12 Vital Retail Metrics & KPIs for Your Business Success

Our retail guide’s last chapter explored ways to boost your store’s success through innovative finance,…

Sean Thobias

November 19, 2024Learning about effective strategies for selecting goods is essential to make warehouse picking more efficient.

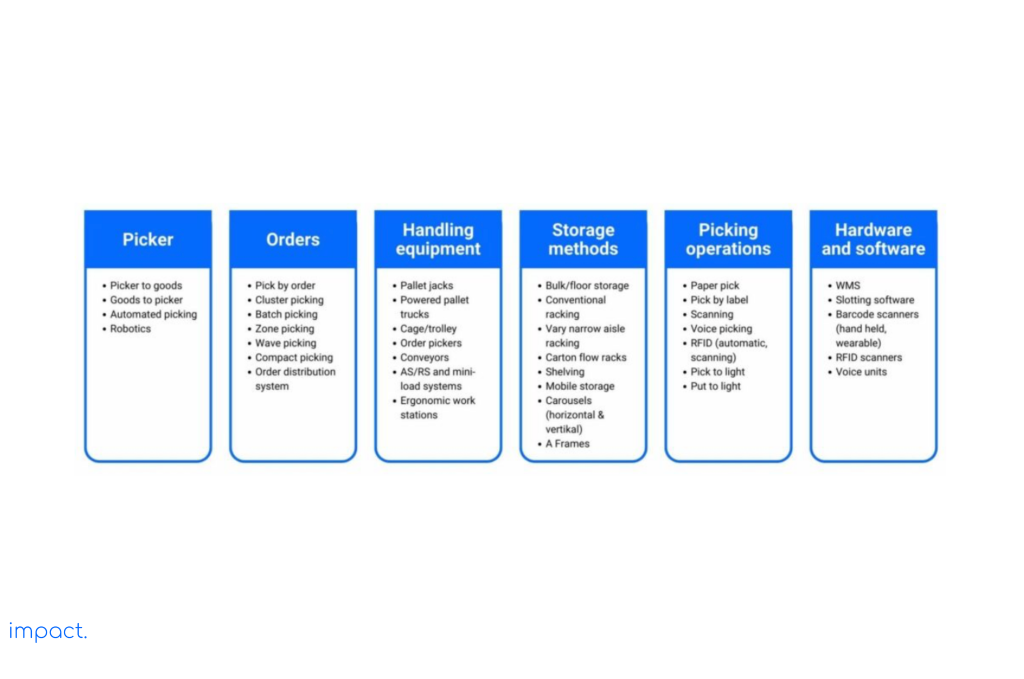

The most expensive part of the picking process is moving between different locations to collect items. It’s essential to have a strategy that minimizes the time spent traveling within the warehouse. The diagram below illustrates how the picking process is connected and presents various options and designs.

Since each company has different needs, they use different picking types and strategies. In this article, we will discuss various picking strategies that your company can consider.

Read more: Understanding Warehouses: Definition and its Importance

When managing a warehouse efficiently, picking strategies are crucial in ensuring that products are retrieved accurately and quickly. This section will explore three primary picking strategies: picker to goods, goods to picker, and automated picking. By understanding the unique features of each process, you can make an informed decision on which one suits your warehouse operations best.

Most warehouses lack automation. As a result, companies still rely on the picker-to-goods strategy to pick goods.

Pick-to-order moves goods from the warehouse to the delivery location with only one handling. The picker takes one order at a time and walks through the warehouse using trolleys, sacks, or forklifts. They follow a specific route by reading a list, using a radio device, or following voice commands. The orders can be individual items, full cartons, or full pallets.

The picker collects the order lines in a specific order and stores them in racks, carousels, or flow racks based on the size of the goods. Individual orders are easier to handle, but orders with multiple items and long distances can cause congestion during picking.

Cluster picking involves selecting individual compartments in trolleys or sacks while handling multiple orders. This method helps reduce travel time. To make cluster picking effortless, we can use equipment like pallet trucks, tugs, or tractors to lift two pallets simultaneously.

In cluster picking, we can also utilize conveyors. Here’s the process: The tote, a container, passes through a barcode reader to obtain a unique ID. Then, the pick-to-light terminal displays all the tote selections on a unique screen. Each terminal instructs us on the number of items to pick and the designated location for placing them.

For instance, if we need to place eight items in compartment B, it will show as “B8” on the screen. Once we pick items for all compartments in a specific area, we return the tote to the conveyor, which moves on to the next room.

The number of orders we can handle in each cluster depends on several factors. These include the number of lines, the number of items in each order, the total space required, and the capacity of the totes, sacks, or carts.

Read more: 6 Warehouse Performance Metrics & Tips for Choosing Them

Batch picking is a strategy where we simultaneously pick goods for multiple orders by breaking down the orders into product components and combining each product line. There are two options: pick by line or pick to zero.

In pick-by-line, there is a risk of returning excess goods to stock. In pick-to-zero, we allocate the correct number of items to customer orders until we exhaust units and lines.

The advantage of this strategy is that it reduces travel time and improves accuracy because two people are involved. However, it takes longer because there are two stages in the process. Batch picking can also increase the number of lines picked per hour, but we still need to count and check the items.

We can use batch picking in cross-dock processes to pick up and allocate products as soon as they arrive at the warehouse. By using batch picking, we can skip tasks like putaway and backfilling, which helps us work faster and more accurately.

We can group orders in different ways. For example, we can combine mail or e-commerce orders into a single charge. Similarly, we can combine orders that contain similar items. We can do this grouping manually, but many people now use Warehouse Management Systems (WMS) to make the batch-picking process easier and more efficient.

Zone picking is a simple strategy where each picker is assigned a specific area to collect goods. The number of zones given to each selector depends on how busy they are, and the WMS generates the instructions for picking.

Here’s how it works: we move orders from one zone to another until we complete all of them. We use different tools like bags, carts, pallets, or conveyors with rollers or gravity to make it easier to move boxes or totes. We must control the number of orders we send to each zone to avoid delays and ensure everyone has a fair workload.

Usually, each zone has 1-2 pickers, and each can handle multiple zones. Batch picking is practical when there are many different products, many orders, and a moderate number of items per order.

The most widely used strategy in this type of picking is “pick by light.” When an operator moves to the following order, a set of lights illuminates that zone, displaying the number of items to pick. Once the selector completes the picking, they turn off the light and move to the location with the subsequent illumination.

In addition, companies actively scan the product barcode before placing it in the tote to ensure it is the correct item. This scanning process speeds up operations and reduces errors. Companies commonly employ the pick-by-light strategy in their operations, especially when they have separate zones for different product lines, such as medicine, dangerous goods, and food.

We schedule the release of wave-picking orders at specific times, such as in the morning or at noon, to align with vehicle departures, recharge cycles, and shift changes. The timing may vary for different areas depending on the time required to select the orders.

The downside of this picking strategy is that it requires reassembling the partial orders in the next step. However, it also allows a second check on the product code and quantity.

The Goods-to-picker strategy is advantageous for various system configurations. Its benefits, as stated by Dematic (2009), include:

Read more: 9 Vital Warehouse Processes You Need to Know

An example of a goods-to-picker strategy is as follows:

The goods-to-picker compact picking system is excellent for handling slow-moving products in retail and wholesale warehouses. It’s also cost-effective for warehouses dealing with different parts and components, like the automotive industry.

Here’s how it works: the product is taken from storage and brought to the workstation using a conveyor. At the workstation, it’s combined with other items and packed into a cardboard box for delivery.

Read more: What is a Wholesaler? Definition, Benefits, and 4 Challenges

The order distribution system is excellent for businesses with many order lines with only a few different products. Carriers move boxes or containers with a single product to various locations where they assemble the orders using a unique light system. This system works well for companies that sell things through the mail or online.

In both of these operations, the workstation is essential. Vanderlande Industries has made a group of workstations that are good for people’s bodies and come in different sizes. They can handle anywhere from 100 to 1000 order lines every hour. Here are the main things about these workstations:

The Rapid Pick workstation by Dematic helps operators work efficiently and prevents injuries like Repetitive Strain Injury (RSI) and fatigue. Operators can adjust the height of the workstation to fit their needs.

The workstation includes good lighting, controls that are easy to use, and visible buttons. You can adjust the screen on the workstation to a comfortable height and angle. The screen displays essential information such as the item’s size, a picture of the product, and where placement location. This feature helps us create a dependable and secure system for taking orders at every workstation.

The workstation also has a helpful feature that automatically organizes the order of picking items. It has two conveyor lines: one for bringing things to the operator and one for placing completed orders. The workstation presents the items to the operator in an easy-to-reach and handle manner.

The operator looks at the instructions on the screen and ensures each item is in the right place in the box by using a machine or pressing a button. Once the operator completes all the orders, the IT system actively sends out the boxes and totes. If the picking process encounters empty totes, the workstation retains them, and the IT system later directs their utilization.

This workstation can handle up to 1,800 units per hour at total capacity, making operations faster and more efficient.

Companies are using system automation to keep up with the competition. They want to be faster, more accurate, and more productive. In 2009, Vanderlande Industries introduced Automated Case Picking (ACP) to lower handling costs by 40%. This system caters to food retailers with high-capacity needs.

The ACP system automatically releases pallets from storage one layer at a time. The AS/RS system stores and transports these pallet layers, reducing the reliance on cranes. To expedite work, companies employ other AS/RS systems.

The ACP system has a lower initial cost and pays for itself quickly. It cuts up to 40% of order-picking expenses, making it a good choice. It also ensures enough stock at the picking area, processes orders fast, and improves service for retail food stores.

Using an automation system offers several advantages, including:

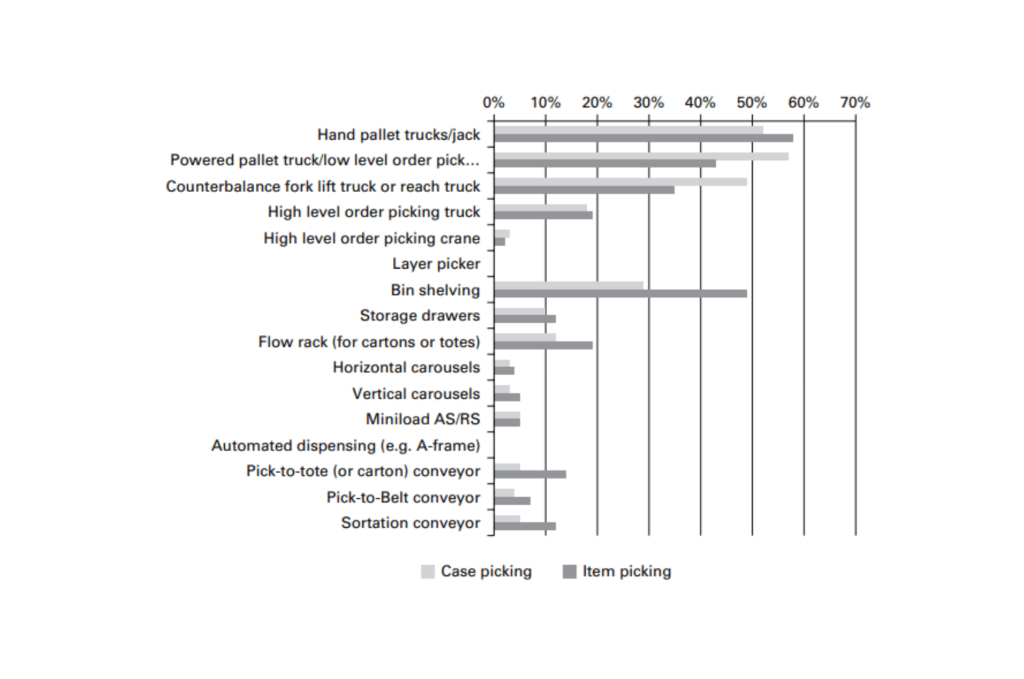

There are still some warehouses that use automation systems for picking. The picture below shows that automation doesn’t have much effect on the warehouse operator.

Source: Warehouse Management; Use of Equipment for Picking

Before switching to automation, ensure operations run smoothly without relying on technology. Once you have achieved this, you can explore using technology to enhance productivity. However, remember that automation necessitates adequate preparation and time for design, evaluation, and implementation.

Here are some drawbacks of automation to consider:

Read more: Warehouse Cost: 2 Determination Systems & Reduction Tips

To work more efficiently, you can use different picking strategies. It’s important to remember that every company has different needs, so their processes and tools will also differ.

The most common picking strategy used in warehouses today is when pickers go to the items. However, there’s another strategy where the goods come to the selector, which can be faster and more cost-effective if automated.

Each company may use different equipment in its warehouse, depending on their specific situation and needs. In the following article, we will talk about the equipment in warehouse operations.

Dematic C. 2009. Goods to Person Order Fulfilment. Dematic CorporationRichard G. 2011. Warehouse Management. Great Britain: Kogan Page Limited.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

75% of digital transformation projects fail. Take the right first step by choosing a reliable long-term partner.