Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

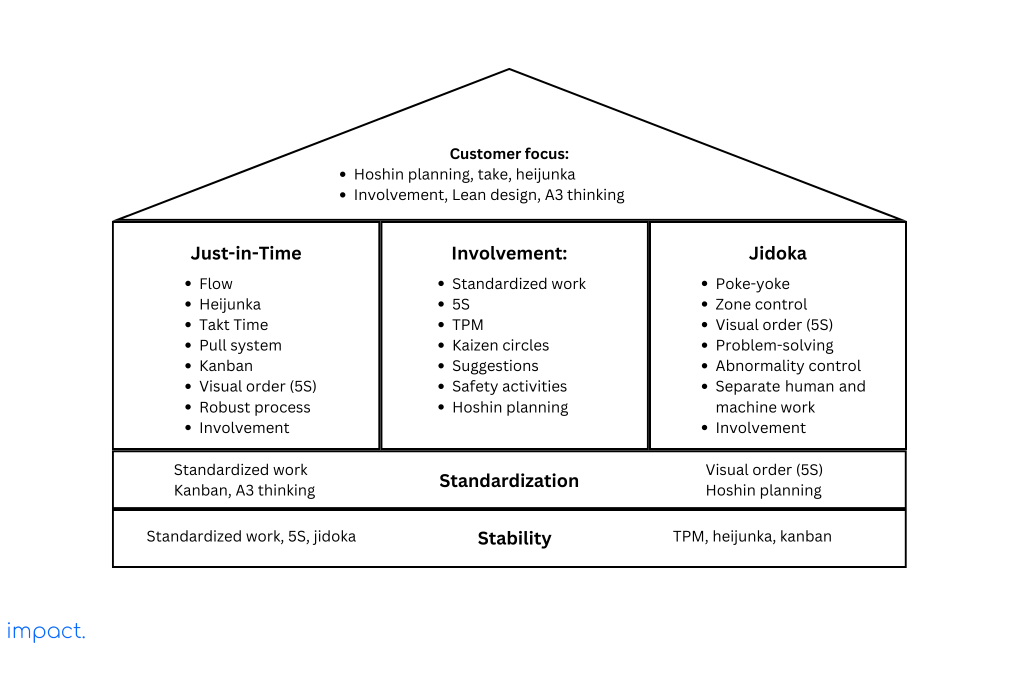

May 17, 2025Total Productive Maintenance (TPM) forms a crucial stability component that lays the foundation of the House of Lean Production. It works hand in hand with 5S, which we discussed in the previous chapter.

TPM, or Total Productive Maintenance, takes a holistic approach to equipment maintenance. Its primary objective is to achieve flawless production by eliminating breakdowns, minimizing downtime, reducing product defects, and preventing accidents.

In practice, TPM relies on visual management to facilitate training and promotion within the workplace.

Now, let’s explore TPM in greater detail and understand how it contributes to creating stability in lean manufacturing.

TPM is a maintenance approach that focuses on being proactive and preventive to ensure equipment works efficiently. When companies implement TPM, everyone in the factory is responsible for maintaining the equipment, which gets workers more involved. TPM helps increase productivity by keeping equipment running, making processes faster, and eliminating defects when used in the right environment.

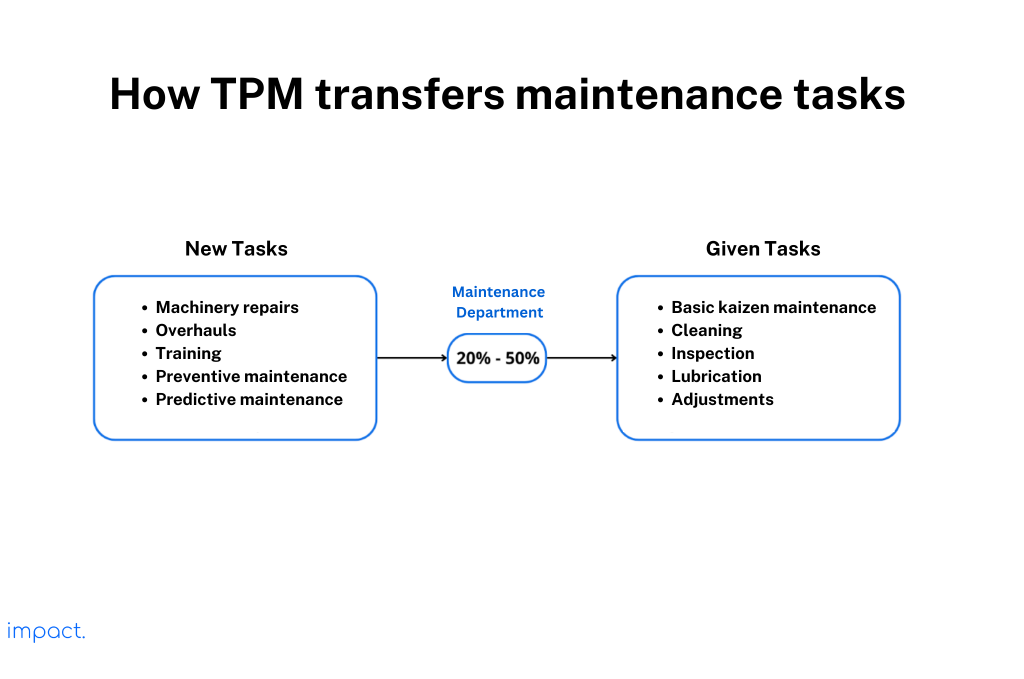

The image above shows how TPM assigns essential maintenance work to production team members, such as inspection, cleaning, lubrication, and tightening. This allocation allows maintenance team members to focus on predictive maintenance, equipment upgrades, repairs, training, and other high-value activities.

The goal of TPM is to achieve zero breakdowns. To achieve this, we take the following steps to maintain production equipment:

| TPM = (Preventive maintenance + Predictive maintenance) – total involvement |

TPM implementation relies on eight supporting pillars. These pillars primarily focus on proactive and preventive techniques to enhance equipment reliability. Here are the explanations of the TPM pillars:

| Pillar | Definition | Function |

| Autonomous Maintenance | The operator is responsible for routine maintenance tasks, including cleaning, lubrication, and inspection. | Operators have greater “ownership” of their equipment.Increases the operator’s knowledge of their equipment.Ensures the proper cleaning of equipment.Identifies emerging problems. |

| Planned Maintenance | Use predicted and measured failure rates to schedule maintenance tasks. | Reduces unplanned stop-time events significantly.Enables planned maintenance during equipment downtime.Improves control over wear-prone and failure-prone parts to reduce inventory. |

| Quality Maintenance | Detect and prevent design errors in the production process. Implement Root Cause Analysis to eliminate recurring sources of quality defects. | Target quality issues by focusing on improvement projects that directly eliminate significant sources of defects.Reduce the number of defects.Catch defects early to reduce costs and avoid unreliable inspections for defect detection. |

| Focused Improvement | Encourage small employee groups to work together proactively, aiming for regular and incremental improvements in equipment operation. | Cross-functional teams identify and resolve recurring issues.Companies combine their collective talents to create engines for continuous improvement. |

| Early Equipment Management | Utilize your knowledge and practical understanding of manufacturing equipment gained through TPM to enhance new equipment designs. | New equipment achieves planned performance levels faster, thanks to reduced startup issues.Simplified and more resilient maintenance is possible through practical reviews and employee involvement before installation. |

| Training and Education | Operators, maintenance personnel, and managers must fill knowledge gaps to achieve TPM goals. | Operators acquire skills to maintain equipment regularly and identify arising problems.Maintenance personnel are trained in proactive and preventive maintenance techniques.Managers receive training in TPM principles and employee coaching and development. |

| Safety, Health, and Environment | Maintain a safe and healthy work environment. | Enhances workplace safety by eliminating potential health and safety risks.Focused on achieving an accident-free workplace. |

| TPM in Administration | Uses TPM techniques to improve administrative functions. | Extend TPM benefits beyond the factory floor by tackling waste in administrative functions.Improve production by optimizing administrative operations such as order processing, procurement, and scheduling. |

The leading indicators of engine effectiveness include:

| Availability = (loading time – downtime)/loading time |

| Performance efficiency = (net operating time – lost time)/(net operating time) |

OEE’s creation is to help TPM initiatives by precisely tracking progress towards achieving “perfect production.

| OEE = availability × performance efficiency × quality level |

Accurate data holds great significance. However, certain managers perceive the time workers dedicate to measure machine performance as a waste. Certain companies only document equipment failure downtime if it surpasses 30 minutes.

Maintenance is all about staying focused. We need accurate records of the equipment’s operation to ensure things run smoothly. It’s not enough to know when things are down. Luckily, technology has made advancements, and we can easily access this data using ERPs.

Most companies can generate valuable data such as Mean Time to Repair (MTTR), Mean Time Between Failure (MTBF), and more with a small investment. By pinpointing hotspots, we can address the root cause of equipment problems by implementing manual processes or adding extra buffers.

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

TPM involves engaging all team members to eliminate six major disadvantages that reduce machine effectiveness. These disadvantages include:

Many companies neglect to track equipment effectiveness, resulting in an average OEE below 50%. The equipment operates at less than half of its maximum capacity.

The leading cause is crashes that result in minor downtimes, which receive little monitoring. Additionally, minor failures that don’t immediately halt operations frequently go unnoticed. One instance of this is when machines operate at lower speeds because of equipment that is worn out or dirty or insufficient debugging during the startup process.

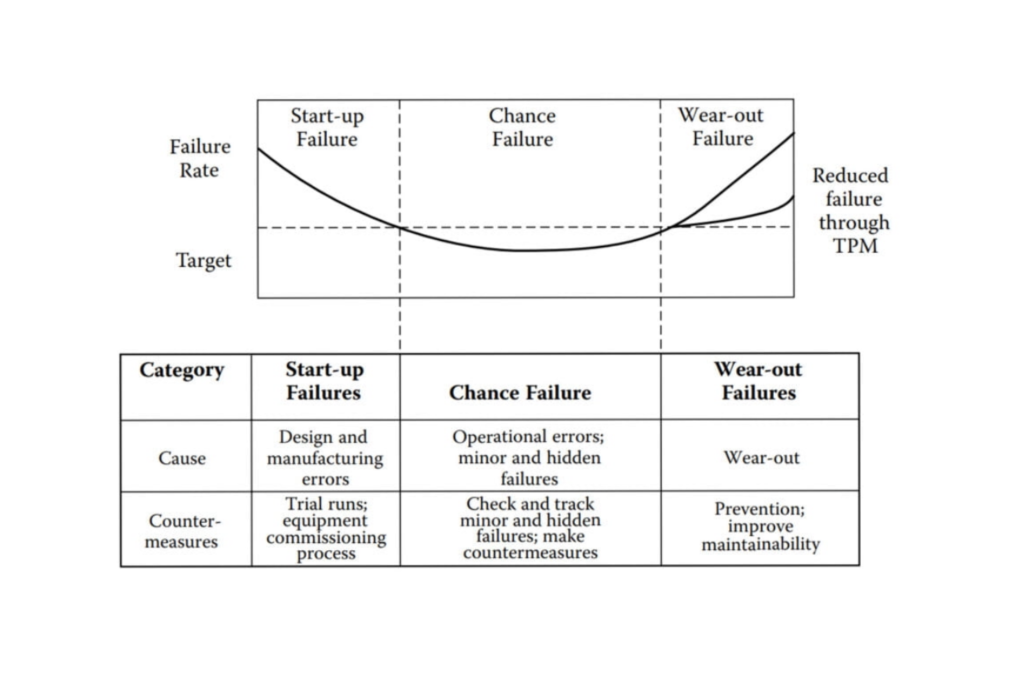

To address this issue, it is crucial to synchronize maintenance tasks with the life cycle of the equipment. The equipment’s life cycle follows the bathtub curve, as illustrated below.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; bathtub curve

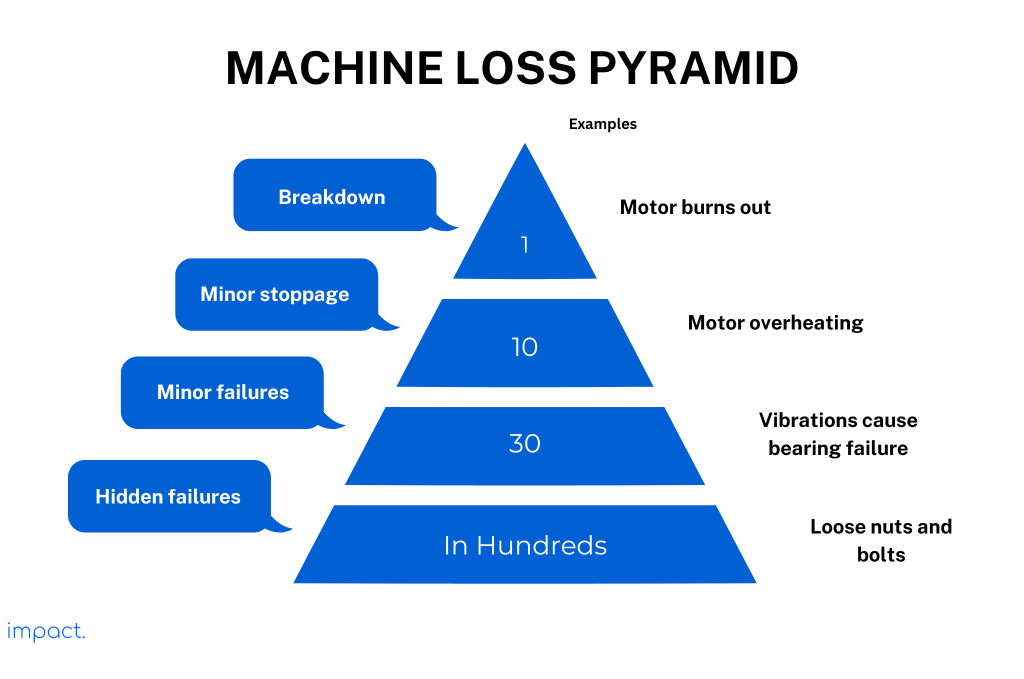

The concept of the Machine Loss Pyramid stresses the importance of spotting small, hidden losses at an early stage. Herbert Heinrich’s book, Industrial Accident Prevention, states that for each severe injury, there are ten minor injuries, 30 incidents of property damage (without personal injuries), and 600 near misses. The same idea applies to machine losses, as illustrated in the following pyramid:

What do the numbers reveal?

Noticing early signs of accidents, like minor, hidden issues, is essential for preventing damage and improving our understanding of the equipment. TPM actively pays attention to these problems and takes action before they become prominent.

Masaaki Imai talks about a production unit at the Tokai Rika plant in Japan where engineers are encouraged to report any small or hidden issues. They keep track of these problems and involve the whole team. Toyota Cambridge also does something similar: Take Action on Accident Prevention. This approach has helped them become a top leader in machine safety and effectiveness.

Involve production team members in checking, reporting, and correcting hidden failures and minor downtimes. Where possible, actively engage the production team in these tasks.

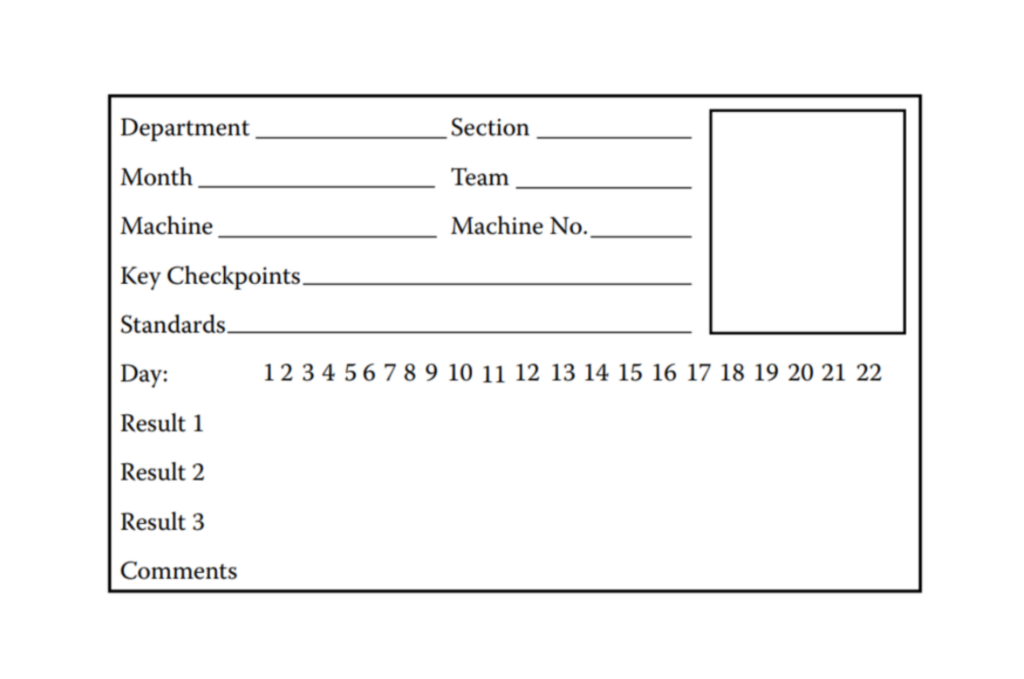

Create check sheets for each major piece of equipment and system to track and display their condition. Refer to the provided image for a generic TPM check sheet.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; TPM Checksheet.

We involve our team members in kaizen circles, practical kaizen training, and other small group activities to strengthen the identified hotspots. This approach enables us to:

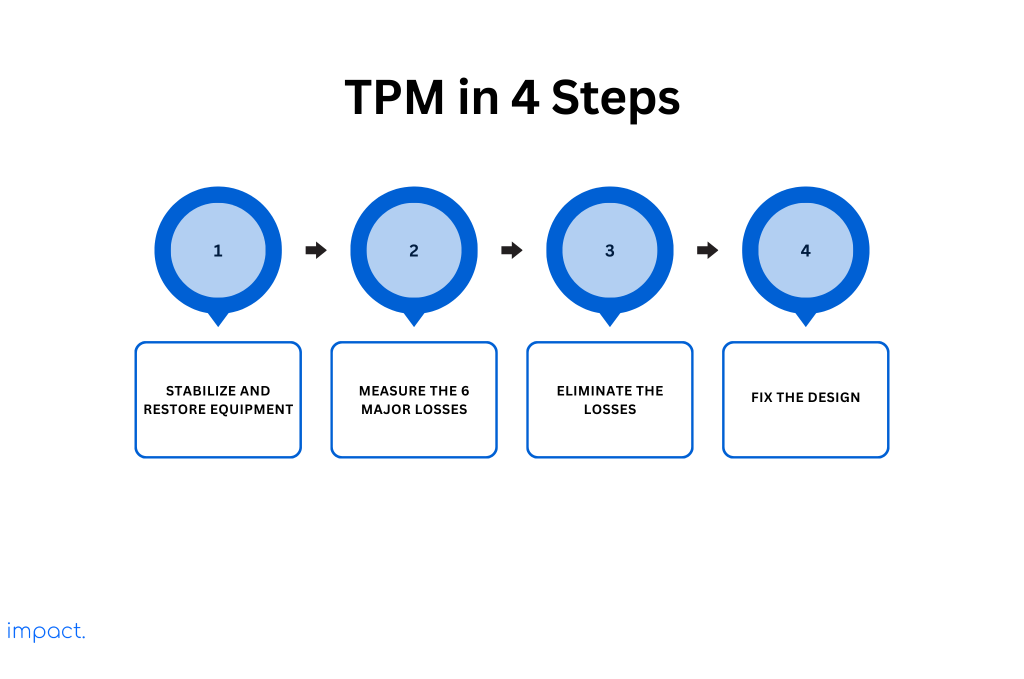

The following figure summarizes the TPM stages, from stabilizing to improving the design. These stages help streamline the production process and enhance its stability.

TPM holds the key to production stability by emphasizing proactive and preventive maintenance. Its primary goal is to maximize equipment operational efficiency and eliminate the six significant losses that hinder productivity.

Companies must actively involve employees in short-term and long-term initiatives to achieve sustainable TPM. They should establish a shared vision for the company’s future and communicate the benefits to employees. In the next chapter, we’ll explore another cornerstone of the House of Lean Production — standardized work.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.