Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

May 17, 2025Barcodes, voice technology, and pick-by-light systems have made picking goods in warehouses faster and more efficient. These advancements are also considered valuable investments.

Today, warehouses use various methods to pick up goods. This article will discuss the most popular picking methods currently in use. We will build upon the information from the previous article, which covered the equipment used in the picking process.

Read more: Understanding Warehouses: Definition and its Importance

When it comes to selecting items from a warehouse, there are several picking methods that companies employ. These methods vary in efficiency, complexity, and suitability for different types of operations. Let’s explore seven typical ways for warehouse picking:

If there is a mistake, write it on the selection list immediately. The supervisor will check it and find another place to get the item if insufficient. Ensure that you write neatly and correctly because you must enter the choice details by hand into the system.

Put the fast-moving things close to where they will be delivered to save time. To do this, people must help and change how things are collected. The people organizing the items will use carts, cages, and machines like forklifts to help them.

The paper with the list of things to collect usually have the order number, code, description, and how many items are needed. The system will show the details of each item in order so that the collection process will be fast and smooth.

We use a list of labels printed on sheets in the pick-by-label method. We organize the tags in the order of item selection. The picker attaches a label to each item and returns any

unused labels. If there are any mistakes, we promptly check them and print more labels if stock is available elsewhere.

People play a crucial role in ensuring the accuracy of the recorded information in this method. As a result, we increasingly utilize technology to enhance warehouse management.

Read more: 9 Vital Warehouse Processes You Need to Know

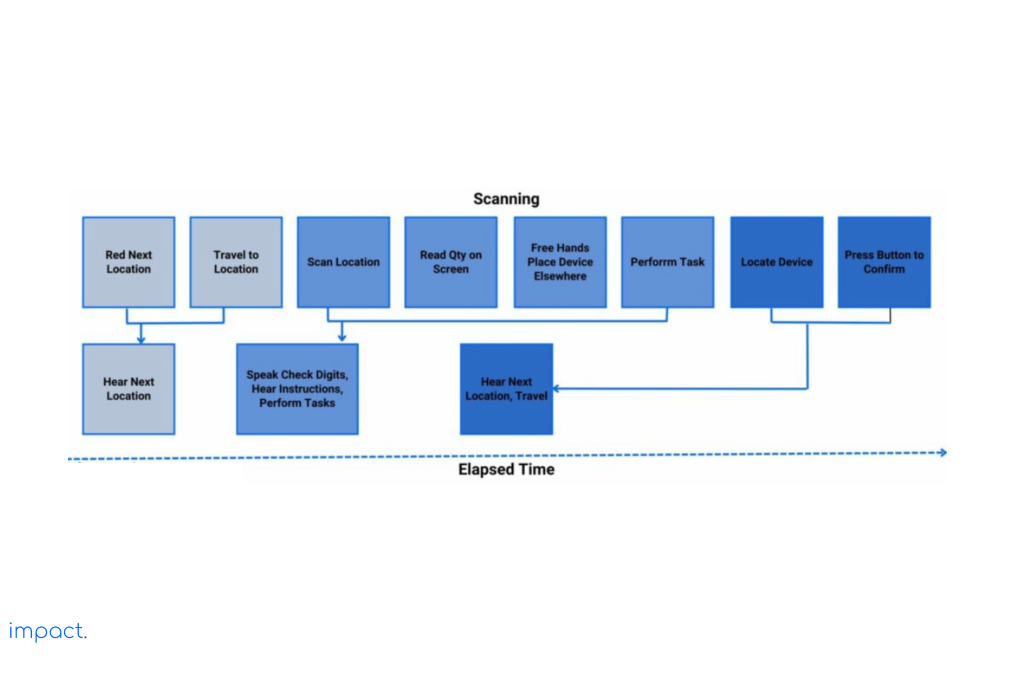

Warehouse management widely uses the pick-by-voice method, particularly during the picking process. Here’s how it works: the operator wears a headset, microphone, and a small computer attached to their belt. The computer receives messages from the warehouse management system (WMS) through radio frequency (RF) transmission.

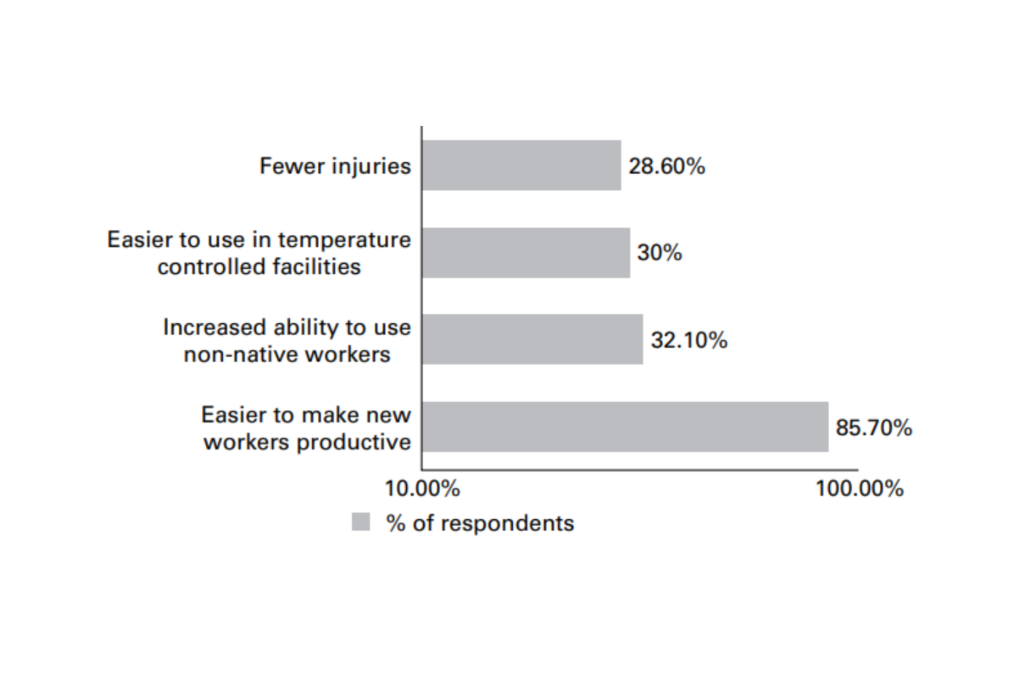

Here are the benefits of using sound technology:

In a survey conducted in 2007 by the ARC Advisory Group and Modern Materials Handling magazine, almost 60% of the people who participated said that using sound technology helped them increase productivity in the picking process by more than 8%.

Additionally, over 83% of the companies that tried this technology reported that it met their goals. The image below shows other advantages of using sound technology when picking up goods.

Source: Warehouse Management; Benefits of voice picking

Pick by voice is now commonly used in the food industry, especially in cold and frozen environments. It offers advantages over paper lists, labels, and barcode scanning because it allows for a hands-free approach. This method of picking goods also improves accuracy for companies.

Improving accuracy can significantly impact your returns. Let’s consider a warehouse that handles half a million cases per week. It has an accuracy rate of 99.8% (resulting in 52,000 errors per year, or 2 per 1000). However, by increasing the accuracy to 99.96% (reducing the errors to 41,600 per year, or 0.4 per 1000), the total savings would amount to £624,000, assuming each error costs around £15.

Companies that have invested in voice systems have seen accuracy rates improve by over 99%. Additionally, they have reduced staff turnover and training time. The image below demonstrates how sound technology can simplify picking, increasing productivity and accuracy.

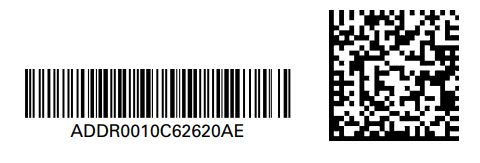

Barcodes comprise different vertical bars in different sizes for letters, numbers, and other symbols. They are commonly used to identify products, mark warehouse locations, label containers (like totes, cartons, and pallets), track serial numbers and organize batches. Two two-dimensional barcodes, like the one shown below, can store more information in a smaller space.

Barcode scanners come in different types: handheld, static, or wearable. Handheld scanners have screens and triggers that decode barcodes, store the data, and send it to the computer. They can read different types of barcodes, and some PDAs and cell phones now also have barcode scanners.

To access the scanner’s data, you can connect it to a computer using a USB cable. Alternatively, you can transfer data in real-time using RF technology. Using handheld scanners helps warehouses collect data faster and more accurately, which boosts productivity.

However, handheld scanners have some drawbacks. Operators must set up the scanner, and placing the scanner on a surface often leads to errors. This movement can cause mistakes in item counting or misplaced items. Companies use stationary scanners that read barcodes as they pass through a conveyor to address this issue.

Advancements in technology allow operators to use both hands by holding a barcode scanner, paper, or roll labels simultaneously. Wireless-enabled computers help operators receive instructions in real-time. These computers, with screens and tiny keyboards, are usually worn on the wrist.

Companies favor wearable equipment that workers can easily adjust and install. The wearable devices are lightweight, ensuring they do not cause discomfort. Utilizing wearable devices speeds up the picking process, reduces errors, and enables significant cost savings.

Let’s say there’s a warehouse with 20 pickers who handle 100 cases per hour (based on eight hours/day, 253 days per year). With an accuracy rate of 99.5%, would be 20,240 errors in a year. However, if the accuracy improves to 99.8%, the number of errors decreases to 8,096. Assuming each mistake costs £15, that adds up to annual savings of £182,160.

Computers can also have user-friendly touch screens and dual imaging. Some can even be voice-activated, which improves picking accuracy. Barcode scanning offers other benefits, too, such as better customer service, shorter training time, fewer accidents and damages, increased employee satisfaction, and more. However, it’s important to note that barcodes can be damaged easily, which makes scanning difficult and may lead to inaccurate information.

RFID (Radio Frequency Identification) is a way to identify items using radio waves. It involves exchanging data between tags and readers using specific frequencies. Library books, toll tickets, and identity cards commonly use RFID.

There are two types of RFID tags: passive and active. Passive tags don’t need their power source, can store limited data, and can only be read. They also have a limited range. On the other hand, active tags have their power source, can store more data, can be read and written to, and have a more extended range.

Passive tags store basic information and rely on a database for more detailed data. For example, in a sorting system, they can identify items and get instructions from a database about where to send them. Active tags have more capacity and can update an item’s status after completing a task. Still, they have a shorter range for writing data.

Regarding cost-effectiveness, it’s better to use RFID for identifying groups of items rather than individual items. Tracking things like roll cages, pallets, and reusable packaging (totes, barrels, and trays) becomes more accessible and affordable with RFID.

One challenge with RFID is that barcodes are cheaper to produce, so they’re still widely used for item identification. Additionally, the cost of running an RFID system depends on factors like the specific application, size of the installation, frequency used, and the number of tags needed.

To implement the RFID application, you will need the following items:

However, there are some drawbacks to using RFID:

Pick to light, also called pick by light, uses light indicators attached to racks, flow racks, pallet racks, or other storage locations. The process starts by scanning a barcode on the tote or shipping carton to indicate the order number. Then, the system sends a message to the operator’s zone, and the pickup location lights up according to the instructions.

Implementing pick-to-light boosts productivity and requires simple training, making it easy to adopt. Many companies already use portable pick-by-light methods to move goods efficiently in the warehouse. Regarding system integration, pick-to-light is uncomplicated; you must download a file with the order number, product code, location, and quantity.

However, this type of goods picking has some downsides. A potential issue is that the scanner needs to be positioned accurately by the operator, as scanning surfaces that are not even can lead to errors.

This drawback can result in the picker going to the wrong location or miscounting items. To address this issue, we now use stationary scanners to read barcodes as they pass through the conveyor, which reduces these challenges.

The Warehouse Management System (WMS) gathers all store orders based on location or delivery time from the distribution center (DC). The goal is to ensure that each store group receives equal products. The staff can adjust the number of locations they handle based on the daily volume.

The required product lines are gathered in large quantities to fulfill store orders and given to operators. Operators use baskets, pallet trucks, or conveyors to move the items. They know where to place items with the aid of a flashing light.

The system immediately sends the confirmed ‘put’ results, updating the information in the WMS in real-time. When using pick-to-light or put-to-light methods, setting up a central processing area to create new layout designs and introducing additional equipment if needed is essential.

To utilize put-to-light technology, you must combine orders and select products in batches. If you don’t receive complete cases of products, you must return pallets or casings to stock. The pack or put-to-light approach can effectively integrate with cross-dock operations, where you receive, place, pick up, and ship goods on the same day if needed.

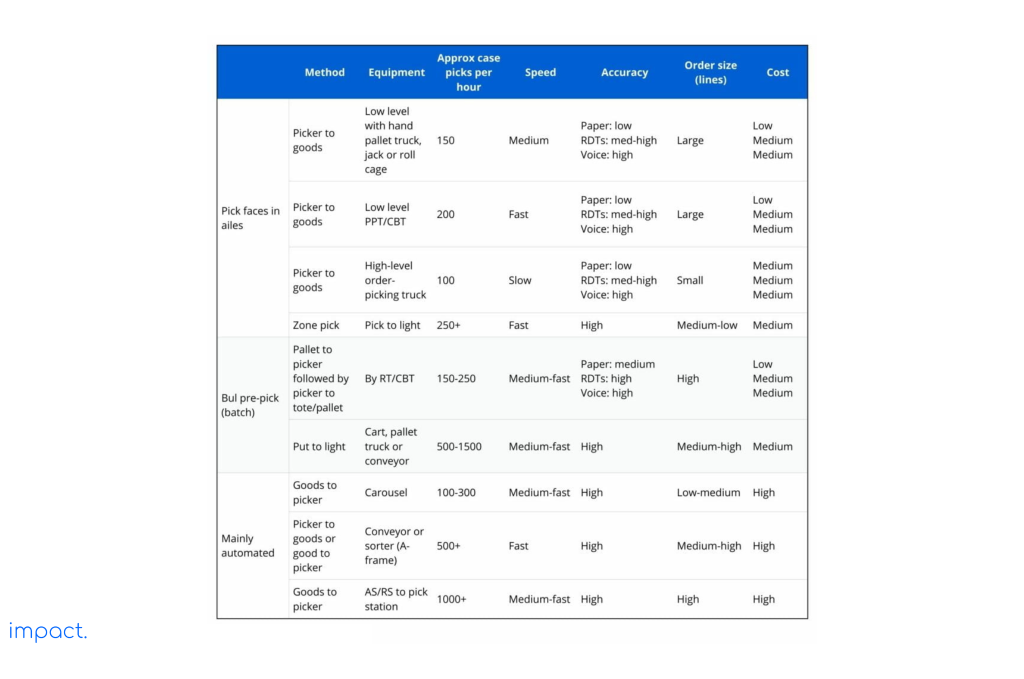

The table below shows different picking methods in warehouse management. In Part One, there is a single-picking process where the picker collects all the items for an order and then moves them to ship. The picker can choose items from a lower shelf or, if there are many different items, from a higher shelf.

In Part Two, there are two main steps. First, we gather a large number of products, like a batch. Then, we sort them into individual orders. Even though it’s a two-step process, we have a high success rate in finding the right items. We also double-check to make sure everything is accurate. To speed things up, we use put-to-light picking to collect all the items needed for a specific order at once.

We use tools like carousels, conveyors, flow racks, and the AS/RS system in Part Three. These tools help us improve accuracy and handle many different products.

Managers have to think about labor, productivity, accuracy, and service level when deciding how to pick items. Here are the things to think about when choosing which picking methods to employ in the warehouse:

A significant amount of money invested will impact the decision between choosing automation or a more hands-on approach. It’s reasonable to expect a three-year payback period when investing in warehouse operations.

Ergonomic problems are also significant when deciding which goods to choose. We need to consider worries about energy use and the potential for taxing equipment that is not environmentally friendly.

The company’s long-term plan will affect the investment in new equipment. Suppose there’s a possibility of moving the business, changing the products, or altering the distribution channels. In that case, we need to think carefully about investing in automation. The cost of taking apart and putting back together the equipment will be prohibitive because it’s a significant amount.

The period before Christmas is not the right time to automate everything. iForce, a fulfillment center in the UK, has decided not to invest significantly in automation. The company’s Managing Director, Mark Hewitt, believes that the large quantity of a few items during the busiest times can make the technology less useful.

A large and stable workforce of skilled and unskilled operators, who receive reasonable wages, plays a crucial role in determining how much automation we can implement. This available workforce helps us gain benefits like increased operations flexibility, lower investment costs, and improved cash flow.

Simulation software enables the comparison of picking solutions like pick-to-light and pick-by-voice. It assesses essential performance indicators such as how quickly operators can pick items and the overall efficiency of order processing. The software recommends the most cost-effective picking method by analyzing the obtained results.

Read more: Warehouse Manager: Roles and 10 Challenges to Overcome

Every company has different warehouse management needs, so they use other methods to carry out operations. To ensure everything runs smoothly, warehouses need the right picking method. There are seven methods to do this:

Barcode scanning is the most commonly used of these options because it’s easy and affordable. Different types of barcode tools can be used depending on the product.

In the following article, we will discuss replenishing stock for shipping.

Richard G. 2011. Warehouse Management. Great Britain: Kogan Page Limited.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.