Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

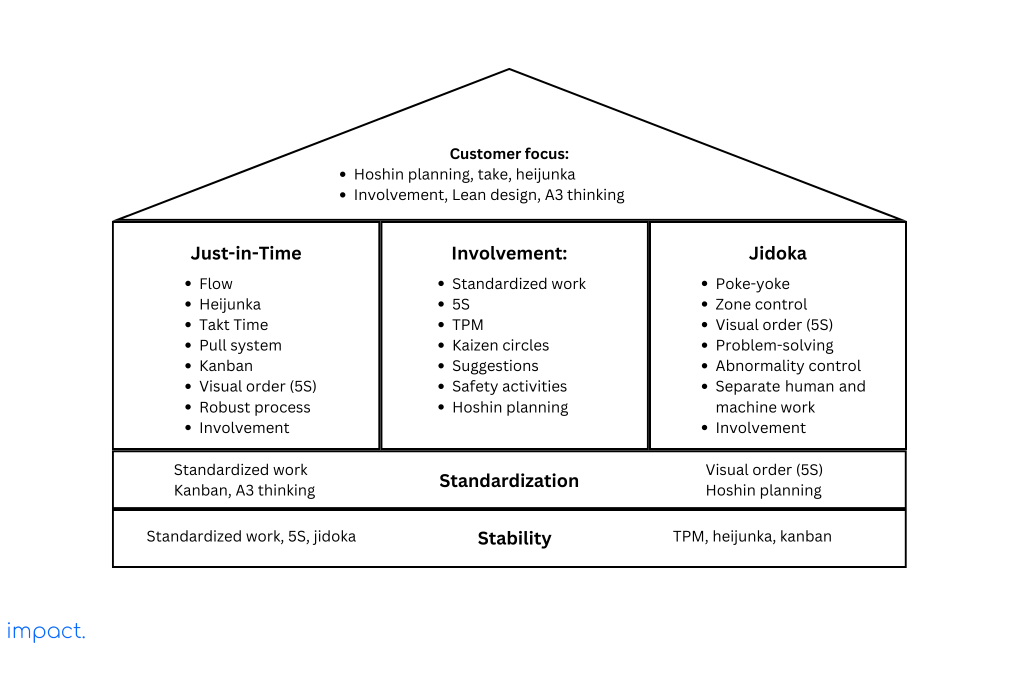

May 17, 2025Involvement is a crucial aspect of the House of Lean Production. When all employees are involved in the company, it becomes easier to spot problems.

Active involvement is crucial in any company and requires careful management, like the production process and product quality. Before implementing it, companies must identify the appropriate method and the skills needed to establish long-lasting engagement.

This chapter will delve into the concept of involvement in more depth, including its definition, purpose, and methods.

Involvement means taking part in an activity. It is crucial to involve everyone in the company to enhance daily operations and find solutions to issues.

Managers used to question whether shop floor workers, who had limited education, could contribute to business decisions. Today, employees are more educated and skilled. That’s why it’s imperative to include them in decision-making. It helps make the company’s outcomes better.

Having a system that is respectful and free from unnecessary difficulties is crucial to maintaining employee engagement. In Lean manufacturing, teamwork involves specific procedures, activities, and behaviors that allow team members to work independently, solve problems, and improve their daily tasks.

When team members are free to work independently, they can continuously improve their skills and contribute the most to the company. This approach also helps boost employee involvement and motivation.

Read more: Lean Manufacturing: Definition & 3 Benefits

The main goal of involving employees is to improve different areas of the company, like productivity, quality, cost, delivery time, safety, environment, and morale (PQCDSM). To achieve this, the company takes the following steps:

In previous chapters, we discussed engagement tools like 5S, TPM, and standardized work. Let’s focus on three main activities supporting company involvement: Kaizen Circle Activity (KCA), Practical Kaizen Training (PKT), and suggestion programs. Here’s a description of each method:

Kaizen, also called continuous improvement, comes from Japan and is a crucial part of lean manufacturing. Its goal is to eliminate waste and inefficiency in manufacturing by regularly making minor improvements.

These improvements include streamlining manufacturing steps, optimizing inventory management, boosting productivity, and enhancing quality control. The Kaizen Circle Activity (KCA) is the most popular engagement activity linked to Kaizen.

KCA has many benefits for employee involvement. Here are a few:

Managers form the KCA and become sponsors when they encounter a problem. A circle typically comprises six to eight team members who convene weekly for at least an hour, spanning a period of six to eight weeks. The team presents their accomplishments and future strategies to management.

The table below outlines the roles and responsibilities of the Kaizen circle. Specific positions may be discretionary. For instance, an experienced team may not require a coach. A seasoned area supervisor can be a facilitator and advisor in such cases.

| Role | Responsibility |

| Circle member | Attend meetings, contribute ideas, select and analyze problems, recommend and implement solutions, and make presentations. |

| Facilitator | Attend training, guide team members through the problem-solving process, attend circle meetings, and complete & submit KCA meeting notes. |

| Advisor | Attend training, provide technical or administrative advice as needed, attend circle meetings, and help coordinate presentations to management. |

| Circle trainer | Develop and conduct training, attend circle meetings when requested, provide problem-solving exercise, and collect meeting notes and management reports. |

| Manager | Encourage circle formation and involvement, regularly check circle progress, provide suggestions, approve recommendations, and attend presentations. |

KCA training usually takes about four hours. To successfully create circles, team members need to undergo training in the following skills:

KCA requires a control department to oversee and handle administration. The main administrative tasks include:

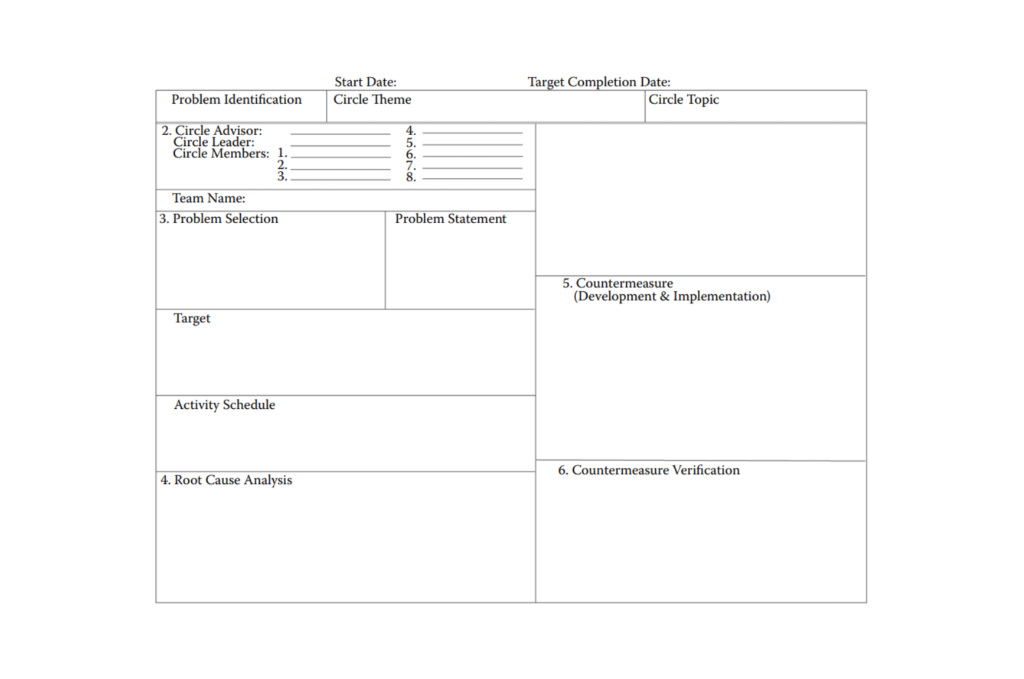

The human resources team can function as the control department for all engagement activities. Here is the general format of a Kaizen circle report:

Source: Dennis, P. (2017). Lean production simplified; Kaizen circle activity (sample report format).

To promote KCA effectively, employ the following strategies:

Managers help promote KCA. They talk to team members daily about important company issues and problems in their area. They also share what management expects from KCA on essential topics.

KCA themes should be simple, like quality or security, when starting. As team members progress, KCA can actively focus on specific company goals, such as reducing certain quality defects or improving assembly processes.

In addition, managers must:

Practical Kaizen Training (PKT) is a one-week intensive program that aims to train team members and supervisors and improve specific processes. Each PKT consists of three to four team members, multiple teams, and PKT instructors or coaches. The training is structured as follows:

Ensure that training for small equipment is readily available and actively encourage workers to participate and develop these skills. The PKT training should specifically address the needs of youth, standardized work, and Kaizen.

Each PKT must provide clear, simple work charts for new design processes or physical changes to achieve the desired outcomes. These charts will promote a shared understanding among all participants involved in these processes.

To achieve success in implementing PKT in companies, companies must focus on the following key factors:

The primary purpose of effective suggestion programs is to involve everyone in the company by directly sending team members’ ideas to management and rewarding their initiative. Management needs to create a positive work environment with specific essential values to make this happen:

Supervisors and area managers should encourage team members to get involved. Here are some simple activities to consider:

Successful suggestion programs possess five key characteristics. These characteristics are as follows:

Make the program rules clear and straightforward. Clearly define the standards for completion time and rewards. A good approach is to assign merit points for each suggestion. Team members can redeem these points as they progress. In addition to cash, we can also give gift vouchers as rewards.

Ensure that the suggestion form is concise and fits on one page. It should include the following information:

Supervisors should assist team members in completing and submitting suggestions. Summarize the program rules and standards on the back of the form. Include both tangible and intangible recommendations.

Set clear standards for feedback, stating, “We will respond to all suggestions within one week.” Having well-defined processes and standards helps us respond quickly. Evaluators play a vital role in reviewing suggestions and recommending appropriate recognition levels.

Make sure each department has enough evaluators to meet the turnaround standards. Companies can also invite evaluators to a special dinner as part of an advisory program and present an award for the “Evaluator of the Year.”

Maintenance groups sometimes have an unfair advantage when enjoying the benefits of advisory programs. Lack of access can lead to resentment and harm the program’s reputation. To prevent this, companies should establish fair rules that treat all groups equally.

Promote advice programs through the following channels:

To measure the effectiveness of promotions, consider the following steps:

Cash and prizes are standard rewards in suggestion programs but don’t provide the strongest motivation. Psychological research suggests that other factors, called intrinsic motivators, may be even more critical. These inherent motivators include:

In suggestion programs, the fundamental principle is “prioritize quantity over quality.” A suggestion program typically takes three to five years to generate a substantial quantity, such as yearly five to ten suggestions per team member. Once the company achieves an adequate volume, it can focus on improving its quality.

We must establish a yearly hoshin culture to set goals for KCA, PKT, and suggestions. The plans for KCA may include the following:

It’s crucial to effectively manage engagement to ensure its long-term sustainability and help companies increase their profits.

Involvement is vital in Lean manufacturing. It helps team members develop their skills and increases the chances of long-term success. Three activities support successful participation in the company: kaizen circle activities, practical kaizen training, and suggestion programs.

Supervisors and managers play an essential role in keeping engagement high. Engagement activities should be fair, easy to participate in, and provide both external and internal satisfaction. To maintain attention, companies can create a hoshin culture. The next chapter will discuss hoshin planning as part of involvement.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.