Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

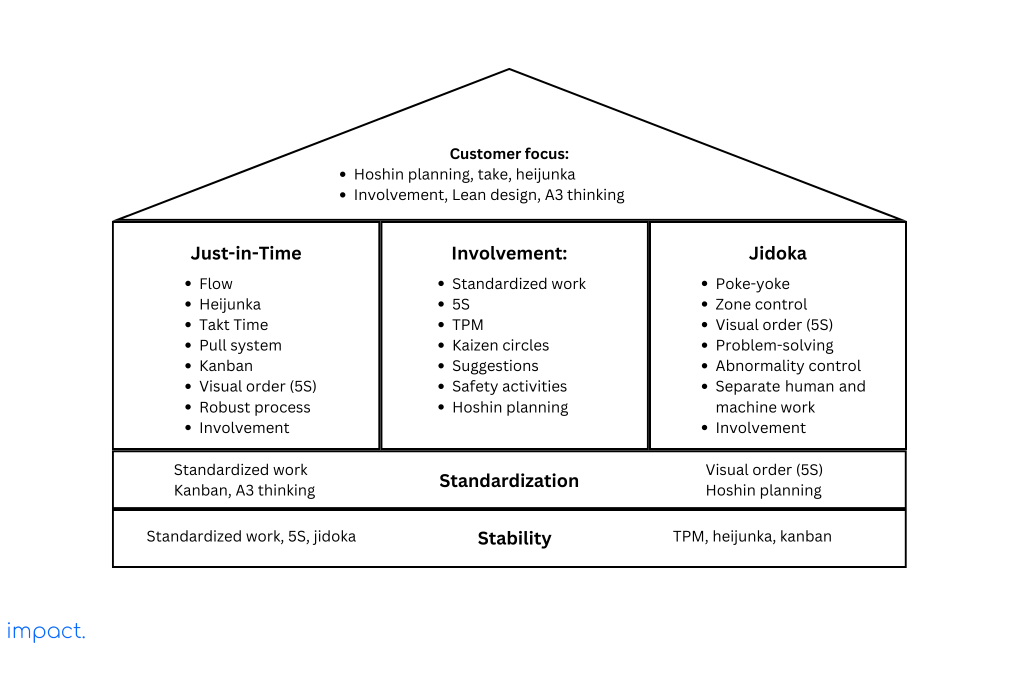

May 17, 2025Jidoka is an integral part of Lean Production, just like the Just-in-Time (JIT) system we discussed earlier. While JIT focuses on product quality, Jidoka ensures quality is built right from the beginning. Without Jidoka, the Lean system could become imbalanced and fall apart.

Jidoka operates on these three fundamental principles:

Let’s look closely at Jidoka, including its meaning, why it’s essential, and how organizations can apply it in practice.

Jidoka comes from the Japanese term “ji-do-ka,” comprising three Chinese characters. Ji represents workers who must stop the production line when they find a mistake and produce a faulty product. Do mean motion or work, and Ka indicates the suffix “-ation.”

Jidoka combines automation and human intelligence, allowing skilled workers and machines to find problems and take appropriate actions to fix them quickly.

Jidoka follows four essential rules to make sure that products are perfect:

Jidoka strengthens the production process by continuously enhancing three key aspects:

In the past, people might not have fully understood the revolutionary nature of Jidoka as an approach to quality management.

Read more: Lean Manufacturing: Definition & 3 Benefits

Sakichi Toyoda, the founder of Toyota, developed the Jidoka concept. In 1902, he made a clever loom that would stop automatically if a thread broke. This invention transformed the industry by allowing one person to handle many looms.

Sakichi’s invention had significant advantages. It reduced mistakes, cut waiting times, and improved productivity. He also suggested it was okay to pause production to find out why defects were happening.

Expanding on Sakichi’s ideas, Shigeo Shingo took the Jidoka concept further. He aimed for “zero defects” and introduced the idea of Poka-yoke. Shingo also developed source inspection to support Poka-yoke. He even showed that it was possible to inspect everything during production without spending too much money.

The high defect rate leads to frequent line stoppages, hindering flow and pull. When this happens, it causes damage to spare parts, leads to wait times longer, and increases production costs.

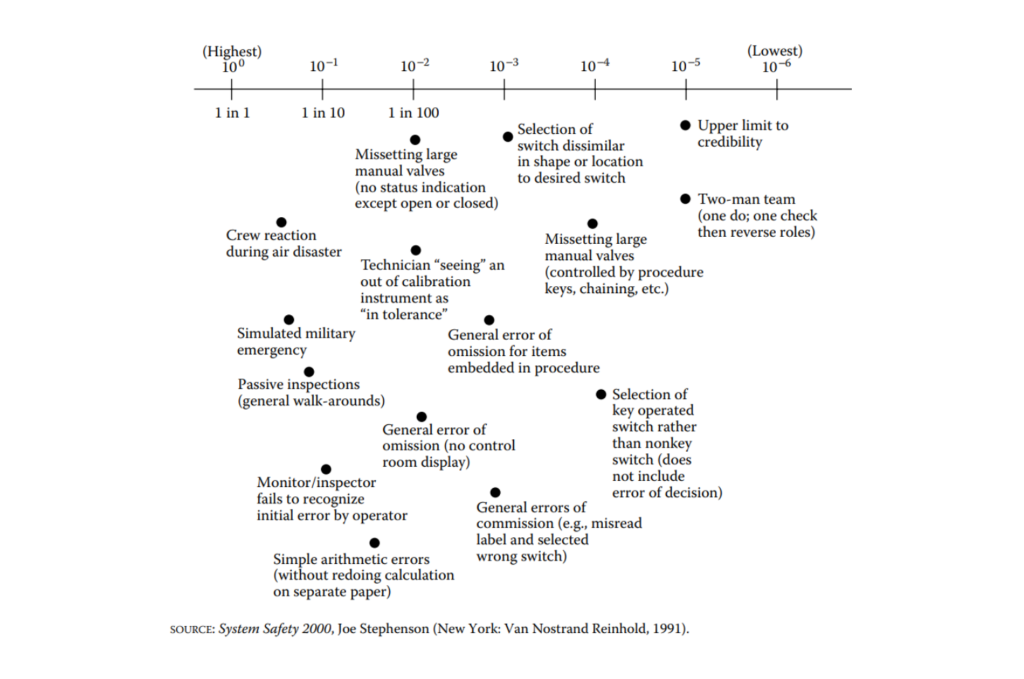

Shingo’s statement holds regarding humans and their propensity for making mistakes. Data from US military and aerospace programs have confirmed that humans often emerge as the least reliable component in complex systems.

The figure below illustrates the typical error rates associated with different human tasks. The left side of the scale denotes the highest error rate, while the right side represents the lowest human error rate.

Source: Dennis, P. (2017). Lean production simplified; Human error rates. (Courtesy of Lean Pathways Inc., Copyright 2014.).

Even extensively trained military personnel exhibit an error rate of approximately 20% during simulated martial law scenarios. The optimal performance level achievable by humans is one error for every 10,000 attempts, equivalent to 100 parts per million.

Based on the data we mentioned earlier about human error rates, it’s clear that we can’t eliminate mistakes made by people in production. So, we need to use different methods to ensure workers are dependable. We discussed these methods in the previous chapter, such as standardized work, visual management, and 5S.

In addition to these methods, Jidoka also uses other techniques to improve worker reliability. Two of these techniques are called Poka-yoke and the inspection system. Here’s an explanation of each:

Poka-yoke means using a simple and cheap device to catch mistakes before they happen or stop them from causing damage.

A good poka-yoke should have these qualities:

The people working on the shop floor usually have the best poka-yoke ideas because they are actively involved in the production process.

Every level of management, starting from the team leader and going up to the supervisor and plant manager, should consider zone control. Let’s take the team leader zone as an example, which includes the team and its work area. The upstream and downstream team zones represent the supplier and customer, respectively.

This way of thinking promotes the development of duplicate controls, which are crucial in reliability engineering. Additionally, Jidoka employs an inspection system to ensure zero defects. Here are some of the inspection systems used in Jidoka:

The purpose of judgment inspections is to prevent defects from reaching the customer or other processes. A different department usually performs these inspections after completing a task. Finding the cause of the problem or providing feedback to those responsible for the mistake is not a significant focus during these inspections. Instead, they focus on determining whether something is good or not.

Informative inspections are all about finding problems, not mistakes, and giving feedback to fix them. They often use statistical tools like sampling protocols and Statistical Process Control (SPC).

Informative inspections are usually better than appraisal inspections, but sometimes there’s a delay in giving feedback and taking corrective action. The most useful informative reviews involve doing self-checks or checking relevant factors one after another.

U-shaped cells help with self-checking by placing the starting and ending processes next to each other. In each check, the following procedures look for defects and give feedback. These repeated checks work best when they cover all the items. The assembly line is a good fit for this kind of inspection.

Source inspections are inspection methods that actively search for faults that can cause defects and give prompt feedback to the source. We can categorize source inspections into two types: vertical inspections and horizontal inspections. Let’s take a closer look at each type:

To inspect this source type, search upstream for the root cause. For example, if there’s a water leak in the assembly, it may be because the paint shop didn’t apply the sealant properly.

Companies can quickly identify and address common problems using a standardized problem-solving approach and implementing a solid feedback loop. This feedback loop operates upstream and downstream and is vital for improving process capability and containment.

In these inspections, we actively search for the root causes of problems within the department. For instance, the lack of techniques to ensure the installation of all required parts often leads to defects and loss in assembly shops.

Toyota actively encourages supervisors in each department to establish feedback loops. These feedback loops enable supervisors to address and correct any defects that arise promptly. They want every supervisor to adopt a mindset similar to that of a small business owner, considering suppliers and customers when making decisions.

To keep improving quality, you need a long-term plan for Jidoka. Here are some essential things to do:

By doing these things, you can keep using Jidoka successfully. Setting yearly goals and having a long-term vision for Jidoka is also helpful.

Include Jidoka in your overall Lean manufacturing plan. When implementing Jidoka, make sure to address the questions mentioned earlier and also consider the following points:

Set annual goals for the following:

Percentage of team members participating in Jidoka activities.

Systems need to foster improvement to maintain jidoka. Start by assessing the company’s process capability level. You can determine the status by assigning scores and ratings to each process.

Ensure the scoring system is straightforward and doesn’t require complex statistical methods. Any team member should be able to evaluate a process and develop improvement ideas. Moreover, the system should offer clear guidance on progressing from one level to the next.

idoka, a concept utilized by Toyota, involves the famous andon process. This process encourages workers to halt production when they identify a significant problem immediately. Jidoka consists of two key elements:

This process allows us to:

Machines are superior to humans in detecting defects and halting processes. However, humans excel in problem-solving, making them better suited for Jidoka implementation.

Read more: Just in Time (JIT): Definition & 8 Application Steps

Jidoka is a concept created by Sakichi Toyoda and expanded upon by Shigeo Shingo. It plays a crucial role in achieving high-quality results at the lowest cost and in the shortest time possible. We can implement Lean manufacturing production by adopting a long-term jidoka strategy.

In the following chapter, we will go into detail about Poka-yoke. The chapter will explore its application and various types.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

See how our ERP provides better value.

Speak with our consultant to explore how we can improve your accounting, processes, and people.