Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

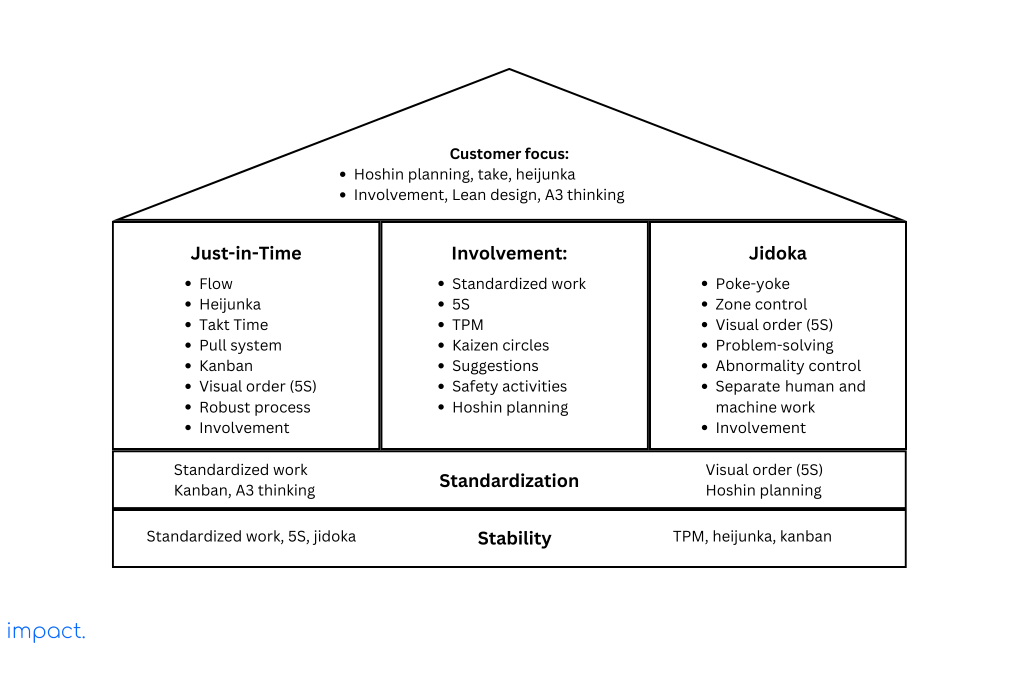

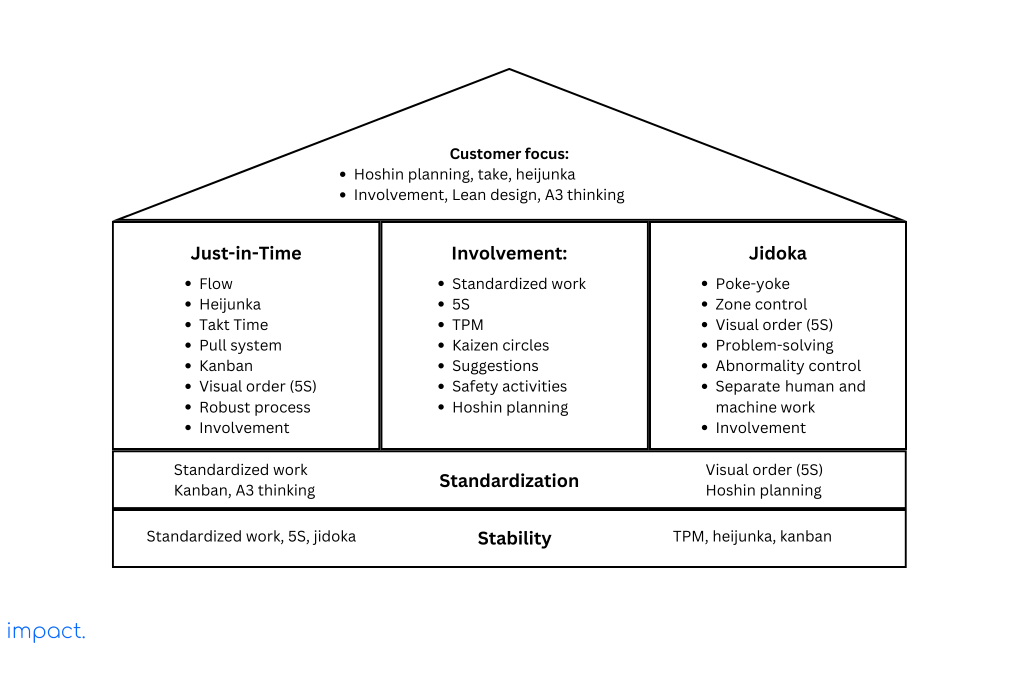

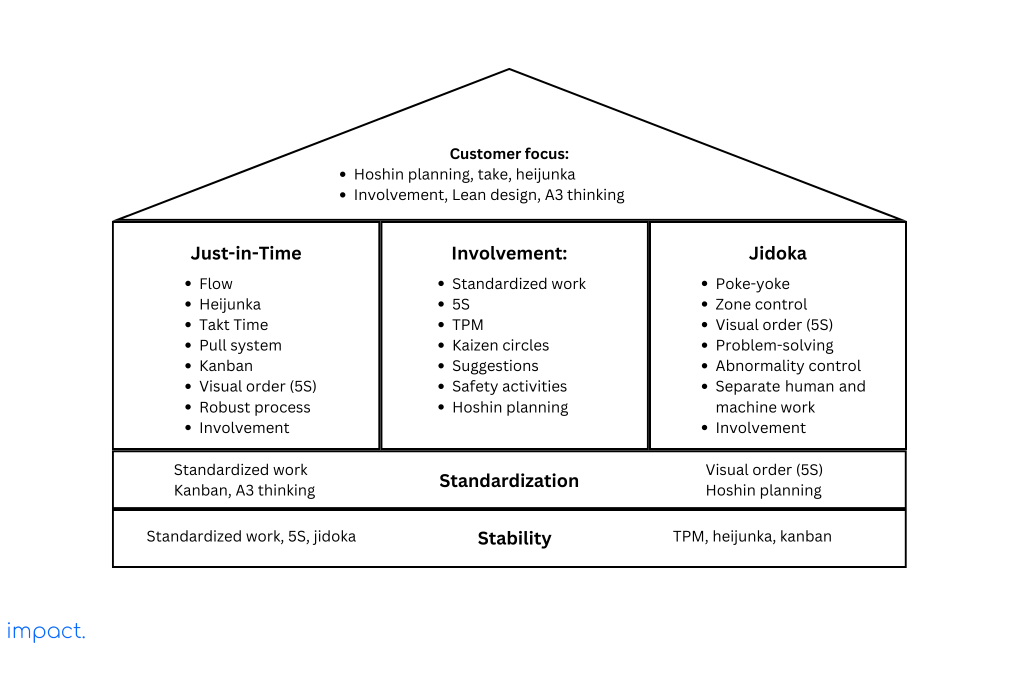

May 17, 2025This chapter discusses another House of Lean Production component: the pull system. As explained in the previous chapter, the pull system is critical in achieving Just-in-Time.

The pull system is a way to control production that helps prevent making too much stuff. It’s one of the main parts of a complete Just-in-Time (JIT) production system, along with Kanban and Heijunka.

In a pull production system, the downstream operations (either in the same or different places) let the upstream operations know what parts or materials they need, how many they need, and when and where they need them. The upstream supplier doesn’t make anything until the downstream customer says they need it.

Now, let’s learn more about the pull system, including what it is, the different types, and the benefits it brings.

The pull system is a technique used in Lean manufacturing to minimize waste in production. By implementing a pull system, companies can start producing a new item only when there is customer demand. The system helps companies reduce costs and better use their storage space.

Apple is an excellent example of how the pull system can be effective. When Apple releases a new product, they create excitement, and customers eagerly buy their products. Apple waits to see how much demand there is; if it’s high, they make more of the product. The level of demand helps Apple use its resources efficiently and operate more effectively.

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

The pull system is a crucial principle of lean manufacturing developed in the late 1940s. It aims to establish a workflow where work starts only upon customer request rather than relying on estimates. By doing so, companies can effectively eliminate waste in the production process and minimize the risk of overstocking.

Furthermore, implementing a pull system enables companies to adopt the Just-in-Time (JIT) approach discussed earlier. JIT is a production model focusing on producing goods to meet actual demand and avoiding excessive production.

In pull systems, companies make and distribute products according to customers’ wants, not based on guesses. They only produce what is needed when it’s needed. This method is best for products with low demand or when it’s more expensive to deal with extra inventory compared to the benefits of excess stock.

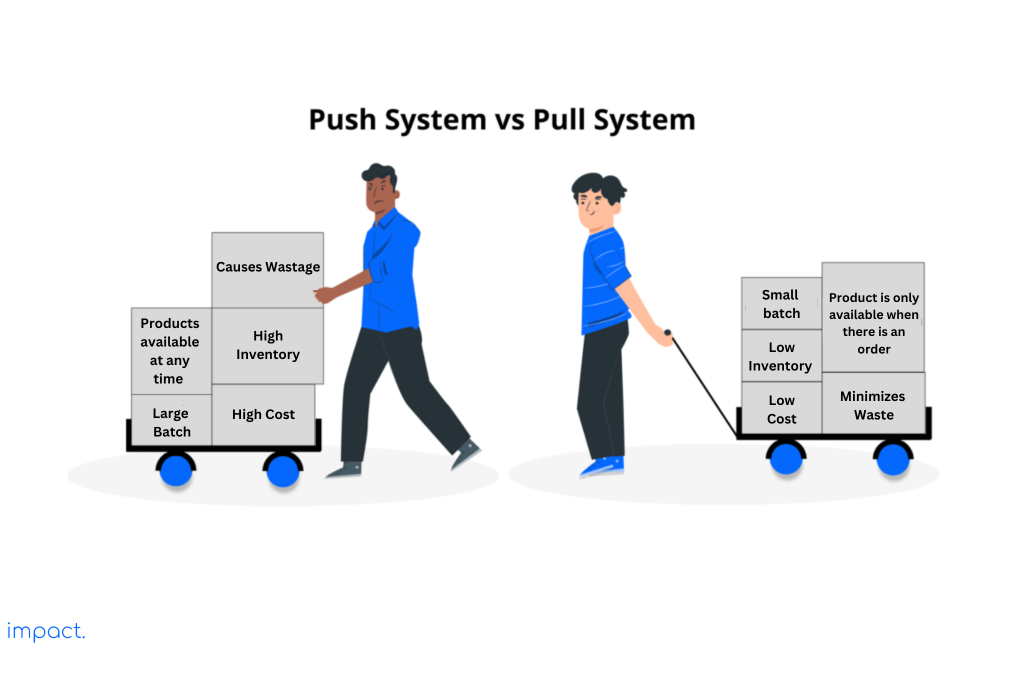

In contrast, push systems rely on estimates of customer demand to determine production. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that demand.

Several factors set these two production systems apart. Here are some of them:

Producers can adopt a hybrid approach combining both systems to achieve mass customization. They can employ the push strategy to stockpile standard products without modifications. Then, towards the end of the production process, they can introduce the pull element, wherein the final adjustments are made based on customer orders.

Selecting the appropriate pull system is crucial when implementing lean manufacturing. Below, we will explain the three types of pull systems:

The type A system, or the Pull System supermarket, is the most commonly used one. Each process has a shop or supermarket holding the company’s products in this type. The company performs production activities to restock the supermarket based on customer demand.

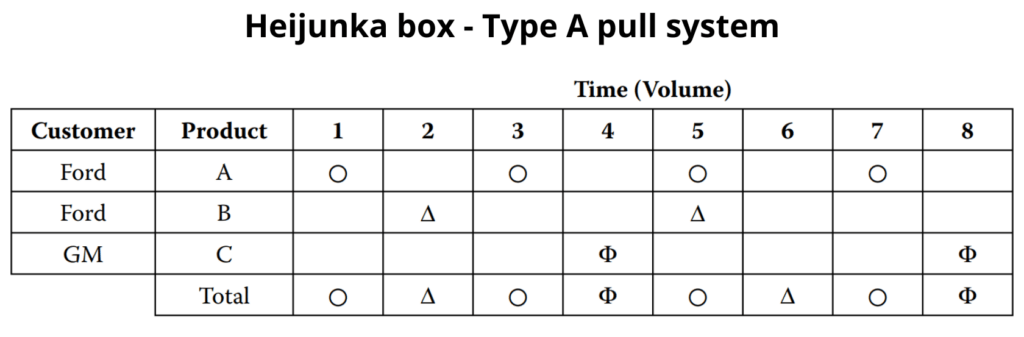

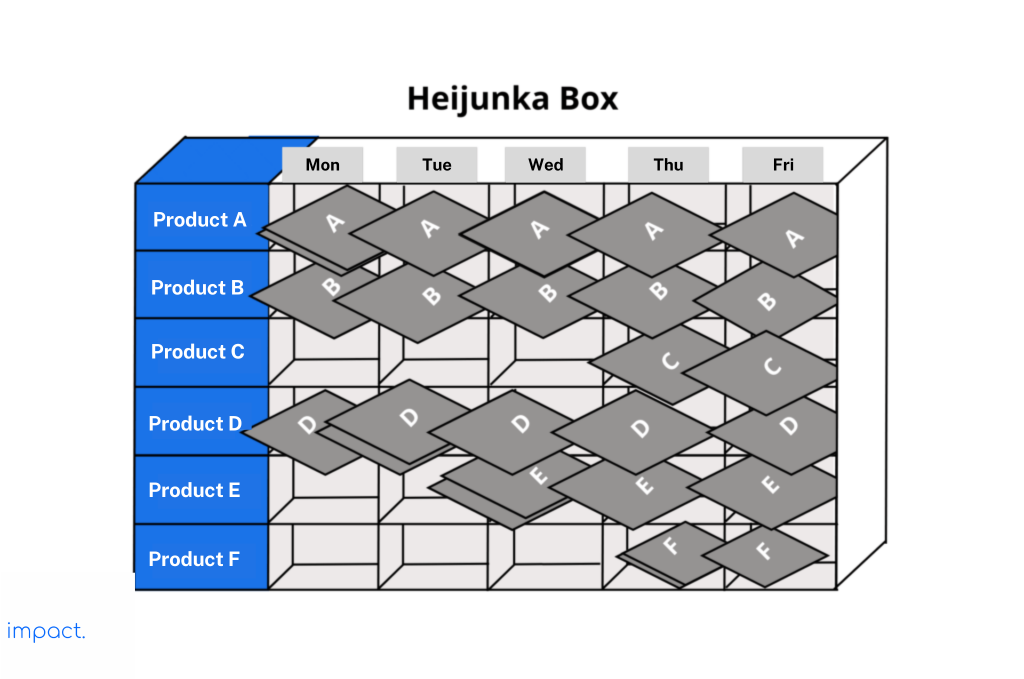

When a customer takes something from the supermarket, a special Kanban card allows production to fill the space. The Heijunka box helps plan the manufacturing process by deciding the order and amount of products needed. The quantity produced depends on the demand and how much customers are taking. In type A, the number of products made by the factory and the time it takes to make them determine the rows and columns of the Heijunka Box.

Source: Dennis, P. (2017). Lean production simplified; Type A pull system.

The type A system works best when frequent customer orders and a short and stable waiting time is needed, like in the car parts industry. It requires having enough finished goods and work-in-progress supplies. The challenge for Type A is strengthening its ability to reduce inventory continuously.

Companies use the Type B or Sequential Pull System when they have low orders and customers have to wait for their orders, such as in custom producers.

Work progresses in a specific order in this system through the FIFO (First in, First Out) pathway. Kanban cards are used to authorize and determine the production sequence through the Heijunka Type B box, also called the sorting box. The company must maintain the order in which they perform and control the work released at each step to ensure a smooth flow in the customs process.

The Type B system avoids stockpiling a large number of finished goods. Instead, it emphasizes the need to maintain short and predictable waiting times. Understanding customer order patterns becomes crucial for the effective functioning of this system. When orders are challenging to predict, minimizing the waiting time for production (less than the time taken) or ensuring adequate storage of finished goods becomes necessary.

The challenge with the Type B system is that it requires strong management to keep it running smoothly, and improving it can be a challenge on the factory floor.

The Type C system combines types A and B, working together. System A handles high-frequency orders, while System B handles low-frequency orders. The Kanban card uses type A and B heijunka boxes to authorize and process orders.

Each type of pull system has its own set of requirements. The Type C system is ideal for manufacturers who produce items with both high and low frequencies.

By using both types selectively, the Type C system allows you to take advantage of the benefits of each approach. You can run these two systems side by side or use them for specific part numbers at different locations.

However, hybrid systems can make balancing work and identifying problems harder. It can also be more challenging to manage and improve processes. So, it’s essential to have discipline and make the combination system work effectively.

Various industries widely use the pull system, including manufacturing, software development, and customer service. It allows professionals to prioritize tasks and prevent team overload in workflow management.

Workers can pull their next task if they can start working on it in a pull system. The system enables better task prioritization and helps the team focus on delivering important work on time.

To achieve higher levels of productivity and workflow efficiency through a pull system, companies must:

Companies should use pull signals to improve their workflow. The easiest way to do this is by creating a visual system that records and tracks essential information. This initial step will help companies understand their work processes better and catch all the critical signals.

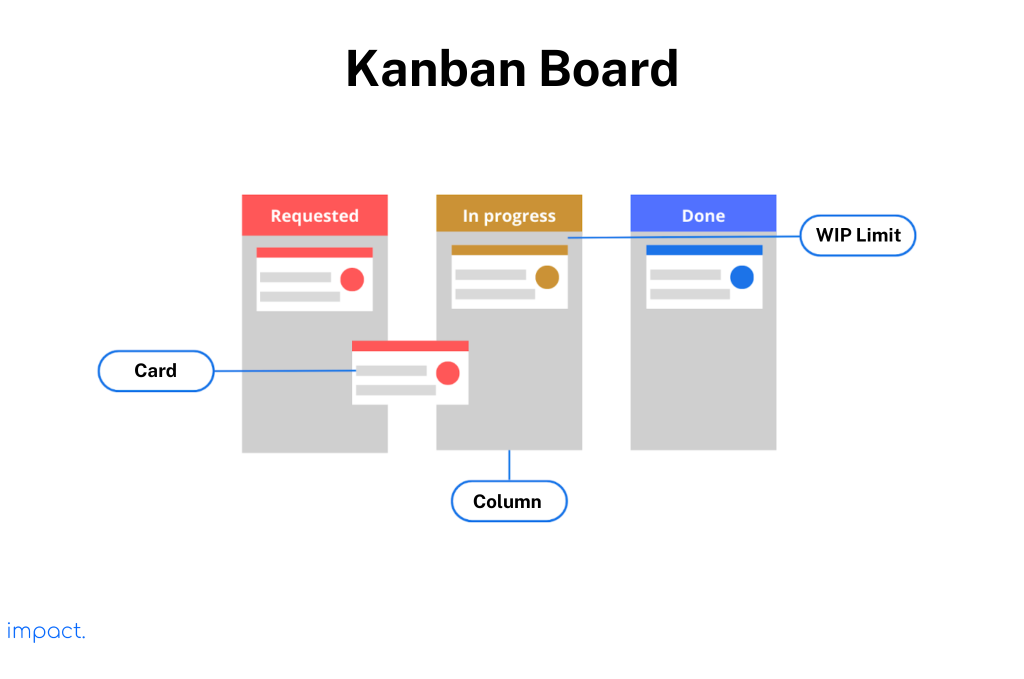

To effectively control a visual pull system, it is crucial to know how to manage it. Limiting work in progress (WIP) is a widely employed approach to handle a pull system effectively, and it stands as one of the fundamental practices of the Kanban method.

Limiting the work on a Kanban board allows for a smooth workflow and easy identification of problematic areas. Kanban boards divide workflow into requested, in-progress, and done stages.

Contrary to the common belief that multitasking increases productivity, limiting the work in progress (WIP) keeps team members focused on a single task until completion.

When focused, your team can achieve excellence and deliver work faster. However, limiting the WIP is insufficient for establishing a continuous pull system. Setting time limits for each task in your system is also crucial.

The time limit may vary depending on the task’s size and serves as a requirement. Neglecting to enforce time limits can result in jobs taking excessive time in the process and decrease flow efficiency.

Read also: Kanban: Definition, 6 Rules, and its Benefits

Pull systems are superior to push systems because they enable team members to concentrate on one task at a time. This approach offers several benefits:

Furthermore, employing the pull system principle enables you to enhance the predictability of your future work. Pull systems empower companies to accumulate historical data on workflow and average task cycle times, fostering a more informed planning process.

The pull system is an integral part of Lean manufacturing. Its main goal is to create a workflow where work begins only when the customer requests it. When implementing the pull system, it’s essential to understand how it differs from the push system. Pull systems generally have three types: A, B, and C, each with advantages.

After discussing pull systems, the next chapter will focus on Value Stream Mapping. This chapter will explain what it means, how it works, and the benefits it provides.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

Heijunka forms an integral part of the Just in Time (JIT) system, which we discussed in a previous chapter. It serves as a foundational element within the House of Lean Production.

Heijunka organizes production that balances daily or monthly work to meet specific targets and requirements. Toyota developed this approach to move away from the traditional method of assembling cars in large batches based on demand.

Here is a detailed explanation of the definitions, methods, and benefits of Heijunka:

Heijunka, or product leveling, is evenly distributing production volumes over time. It helps companies respond to changes in demand and make the most of their capacity.

Some assembly departments prefer sticking to one product for a long time to avoid switching, but this choice has drawbacks. The wait time may be longer if a customer requests something that is not currently available. To improve this situation, the company may consider investing in a pre-made inventory to increase the chances of having what the customer wants.

Using Heijunka, we experience the following advantages:

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

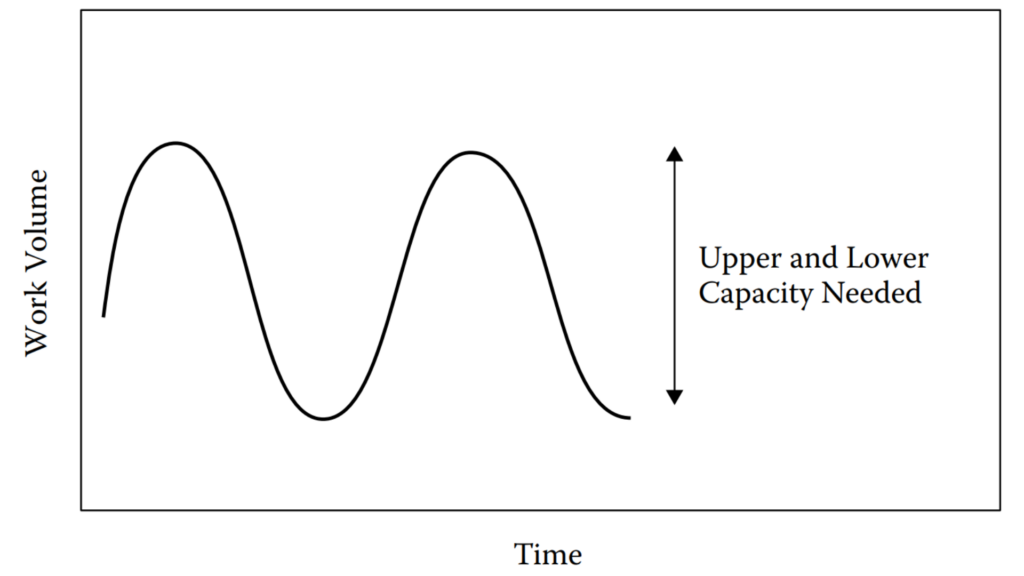

Heijunka helps companies determine how much staff, equipment, and materials they need. Imagine if the number of jobs changes, like in this graph. If we prepare for the busiest times, we won’t fully use our resources when things are slow. However, if we focus on the slower periods, our people, equipment, and suppliers will struggle to keep up during the busiest times.

Source: Dennis, P. (2017). Lean production simplified; Peaks and Valleys in work

Heijunka is a method used in Lean Manufacturing to make production smoother and prevent overwhelming workloads. Using Heijunka, you can create products based on customers’ orders instead of making many items at once. This method helps the company economize by having fewer extra items when there aren’t many orders.

Another benefit of Heijunka is that it keeps things under control when there’s a sudden increase in demand. The processes and teams can work steadily according to the average sales rate so they don’t get overwhelmed.

How does the company adapt to changing customer demands? Here are three preferred options for handling this:

You can use the first two options daily, but they are difficult. It is challenging to adjust takt times when switching operators because it requires changing standard work charts and retraining or rehiring employees. New facilities implementing Lean production may face initial struggles. The company must maintain the new takt time for at least a month.

At Toyota, we handle slight variations in demand by implementing a small amount of daily overtime or occasional weekend shifts. For more significant seasonal variations, we adjust takt times. To be prepared, we develop standardized work in advance for different takt scenarios.

Heijunka helps you provide a steady flow of value to customers and respond to changes in demand. The Heijunka method uses two ways to balance production:

To create a smooth workflow, stop batch processing and concentrate on completing orders, which will help reduce inventory costs. Only start new tasks when you receive orders. If a company gets a steady stream of new orders, it might be more realistic to change the workflow to handle the demand.

Using Heijunka helps you match your production with the average number of orders you get. For example, you usually get 20 orders weekly. Still, the daily numbers change (like three on Monday, ten on Tuesday, five on Wednesday). In that case, you should use Heijunka to make production even by volume.

When you do this, you create a steady workflow that handles five orders daily to meet the usual demand by week’s end. As a result, your operation can run smoothly, even when charges increase during the week, without any extra stress.

When managing a product portfolio, Heijunka also comes into play. It enables you to balance production by considering the average demand for each product and aligning your work accordingly.

The core principle remains unchanged: you produce enough of each item to fulfill the average customer demand for the product portfolio. For instance, if you receive ten orders per week for Product A, two for Product B, five for Product C, and an average of three for Product D, you should increase your production capacity to meet 20 products per week.

In this scenario, however, Heijunka becomes essential in raising your production level to satisfy each product’s demand. Toyota developed a visualization tool called the Heijunka Box to tackle this challenge. It helps them determine the required number of vehicles to produce for each model.

The Heijunka Box scheduling tool helps you visualize and complete the work items required to meet your average customer demands. It functions by arranging the production order based on the average request for each product order, ensuring optimal flow.

The heijunka box resembles a grid that reveals the products your team must manufacture each day of the workweek. Each row represents a different product, while each column signifies a specific day. The box contains the work items your team needs to complete.

You can visualize the heijunka box in different ways. You can draw it on a wall or window and use sticky notes for the work items. Or you can make an actual box if you want.

Depending on the time available, you might need to place some or none of the orders in each box. In the Toyota Production System, a Kanban card represents each item in a heijunka box, and it progresses through the manufacturing process.

Heijunka is used to distribute and mix production volume evenly over time. It offers two approaches for implementation: leveling by type and leveling by volume. Applying Heijunka can streamline the production process, leading to several benefits.

The upcoming chapter will explore the three types of pull systems in Just in Time (JIT).

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

The production process requires completing several stages. One of these stages is called Work-in-Progress (WIP). WIP is a middle stage that comes before the final product is ready. In Kanban, which we discussed earlier as part of the Just-in-Time (JIT) concept, limiting the amount of WIP is essential.

By setting a maximum number of items allowed in each stage of WIP, companies can ensure that they can handle their workload effectively. Now, let’s take a closer look at what WIP means, how it works, and provide some examples to understand it better.

In production and supply chain management, “Work-in-Progress” (WIP) refers to unfinished work that is still in progress. The WIP figure shows the value of products at different stages of production. However, it is essential to note that the calculation does not consider the worth of unused raw materials.

Work-in-progress includes raw materials, labor, and overhead expenses for products in various production stages. It is part of the inventory asset account on the balance sheet. These costs are then moved to the finished goods account and eventually to the cost of sales.

Read more: Lean Manufacturing: Definition & 3 Benefits

Reducing the number of items in production units will simplify accounting procedures and offer several other benefits for companies. These reasons include the following:

In the production process, there are three main types of inventory and stages:

Three inventory items are categorized based on the product’s completion. Work-in-Progress (WIP) is listed separately when a company prepares its balance sheet. If the amount is minimal, the company can combine it into a single line item.

In accounting, WIP is a type of inventory companies see as a current asset. Companies and accountants work hard to keep WIP inventories low as reporting period gets close. They do this because it can be challenging to determine the exact costs of WIP items.

Companies have different ways to solve the problem. Here are two options:

Accountants use different methods to determine how many units are still in manufacturing. They usually look at the percentage of money spent on overhead, labor, and materials to determine the number of items still being worked on.

The first costs incurred are usually for raw materials because you need materials before you can start using labor. Organizations typically keep track of the total cost of raw materials in a work account ledger.

The following is a rough calculation to estimate the amount of work in progress:

| Initial WIP + production costs – goods production costs = Result WIP |

Companies typically rely on a percentage of their total overhead, labor, and materials costs to calculate the number of partial products or jobs in progress. For instance, a construction company charges its clients based on the project’s progress. This charge could be a fixed percentage, like 25% or 50% upon completion.

Work-in-Process is a term used for goods that are not yet fully finished. They are also called goods-in-process. Work-in-Process usually refers to products that don’t take long to go from raw materials to the final product. Examples of Work-in-Process are things like manufactured goods.

On the other hand, Work-in-Progress refers to assets that take much time to complete, like consulting or construction projects. There are some differences between these two terms:

| Aspect | Work-in-Process | Work-in-Progress |

| Scope of work | There are repetitive steps and smaller production quantities, but more frequently | Represents a large job that was done once and took a long time |

| Industry | Many found in the manufacturing industry | Usually found in the construction industry |

| Financial statements | Included on short-term asset items | Included on long-term asset items |

| Asset liquidity | Easier to liquidate | More difficult to liquidate |

However, this distinction is not the norm. Both terms can refer to an unfinished product.

The stage of completion and marketability of inventories distinguishes WIP and finished goods. WIP represents materials in the process of being developed or assembled into a final product.

On the other hand, finished goods are at the last stage of inventory, indicating that product development is complete and ready for sale to customers. WIP and finished goods signify the intermediate and final stages of the inventory life cycle, respectively.

Typically, what one company considers finished goods may be regarded as semi-finished goods by another. Each company has its criteria to classify items as WIP or finished goods. The difference between work-in-progress (WIP) and finished goods is determined by how much of the completed inventory.

Read more: Just in Time (JIT): Definition & 8 Application Steps

Let’s look at the production process of a tire manufacturing company as an example of Work-in-Progress (WIP):

Work-in-Progress (WIP) is unfinished work that still needs to be completed. It includes costs for things like overhead, labor, and materials. The fewer WIPs there are, the more efficient the company’s production and accounting processes will be.

Once you grasp the concept of Work-in-Progress, the next chapter will

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

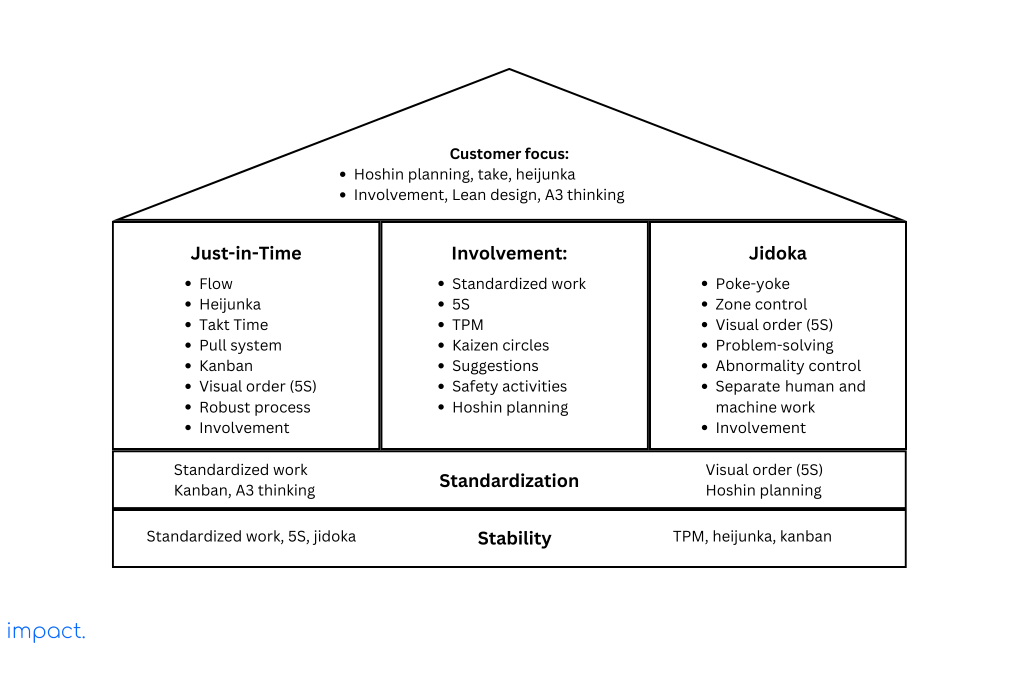

Just in Time (JIT) forms an integral part of the House of Lean Production. It is a strategy to align company supply with demand, avoiding excessive production (overproduction).

Overproduction is a significant issue in the manufacturing industry, particularly in the fashion sector. One commonly employed strategy to address this problem is the Just in Time inventory system.

In 2018, Burberry had to burn unsold products worth US$36 million, and H&M struggled with unsold stock valued at US$4.3 billion. These situations pushed companies to explore different approaches, like using Just in Time (JIT) in their inventory management, to boost efficiency.

Let’s explore Just in Time more thoroughly, including its definition, principles, and advantages.

Just in Time (JIT) is a strategy that helps produce the right products at the exact time and amount needed. It improves efficiency by making what is necessary for the production process. JIT also reduces inventory, simplifies manufacturing processes, and saves manufacturing costs.

Toyota introduced Just-in-Time (JIT) in the 1950s as a direct response to specific problems:

Toyota depends on the entire Lean Manufacturing system to back up JIT. They have consistently improved how they use JIT. In the 1980s, JIT, along with quality circles, Statistical Process Control (SPC), and other Japanese innovations, were introduced to North America.

Conventional manufacturers adopt a system where they “push” their products, disregarding actual demand. They rely on a projected need to create a master schedule. Each department receives daily orders for the final assembly of the required parts. This approach often leads to long changeover times and the production of large batches.

However, this method hinders effective inventory tracking. Parts shortages are frequent, prompting the need for “just in case” supplies as a protective measure. Consequently, companies require larger spaces or facilities and an increased workforce. The use of extensive facilities and batches isolates workers and hampers communication.

Companies have developed various systems to facilitate the implementation of Just in Time, which helps solve problems and encourages more efficient innovation. In the 1970s, computerized Material Requirements Planning (MRP) replaced manual scheduling. This change significantly improved the process. A sound MRP system can keep track of inventory, order materials, and give instructions to each department for what they need to do next.

Even though there have been some improvements, we still face a few problems, such as product defects, equipment downtime, unexpected replacements, and other unforeseen events. As a result, our production schedules often struggle due to too many or too few parts — posing challenges for downstream operations.

During the 1990s, it transformed and became a robust Enterprise Resource Planning (ERP) system. This system could handle various company tasks, including production, logistics, maintenance, quality, and human resources.

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

JIT manufacturing follows a simple principle called pull production. It means making products based on customers’ needs, not just guesses or forecasts. This principle helps manufacturers quickly respond to changes in demand, avoid making too much or storing unnecessary items, and better control their inventory.

Another critical part of JIT manufacturing is the focus on continuous improvement. Manufacturers keep looking at their production processes to find and fix any problems or inefficiencies. By doing this, they can make things faster and produce higher-quality products.

JIT production has a few basic rules:

Womack and Jones defined the concept of supporting continuous flow and pull. Now, we will explore the definitions of these ideas:

Companies can improve the flow of their operations by implementing the following approach:

Most managers say that goods and services go through the system, and management reduces complex systems’ performance variations. The current system needs to be scrapped entirely and rebuilt with a focus on providing value to customers.

Pull refers to the condition where upstream producers cannot produce goods or services until downstream customers make specific requests. Companies cannot manufacture unless customers actively order their products or services.

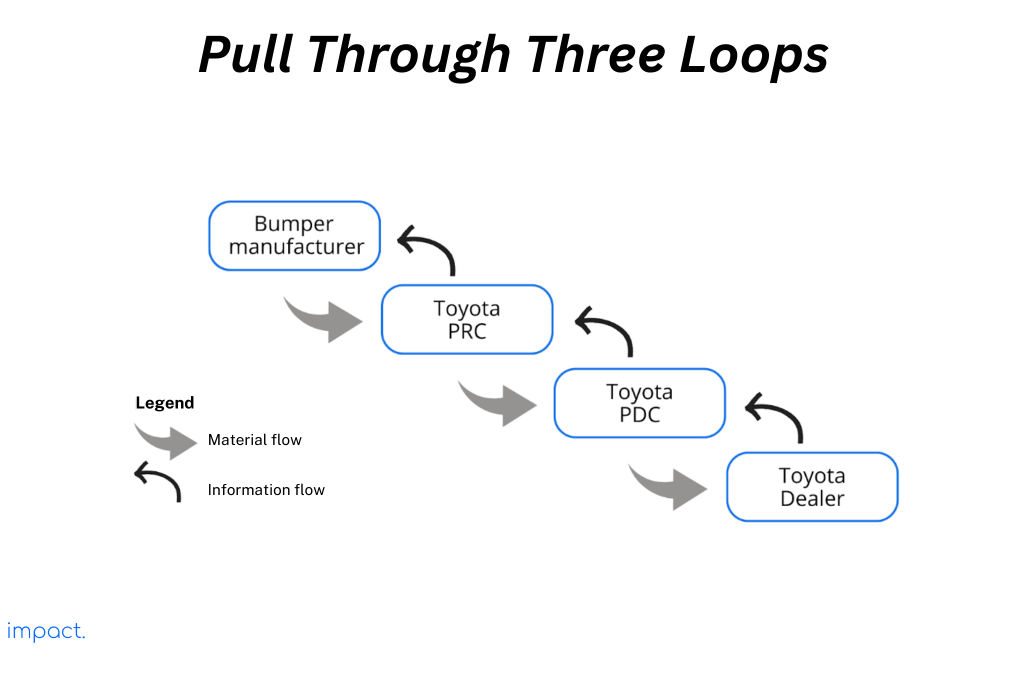

For example, you accidentally back up your blue Toyota Camry 2000 into a mailbox, damaging your bumper. You would head to your local Toyota dealer for assistance in such a situation.

The dealer would promptly install a replacement blue Toyota Camry 2000 bumper, which would, in turn, create a space in their shop area. This gap would signal the nearby Toyota Parts Distribution Center (PDC), requesting a blue Toyota Camry 2000 bumper to replace the one they installed on a customer’s car.

PDC ships new bumpers to dealers and works with the Parts Redistribution Center (PRC), where Toyota suppliers send their parts. PRC requested that the manufacturer produce a blue bumper for the 2000 Toyota Camry and then forwarded it to PDC.

The bumper manufacturer sets aside specific time slots for making blue bumpers. The table below shows the three steps, or “pull loops,” to get the bumper from the manufacturer to the dealer.

If dealers didn’t have a pull system, they would need to stock multiple parts shops. It would require PRC and PDC to maintain large warehouses at a significant expense from an early stage.

Tracking parts becomes increasingly difficult as the size of the warehouse grows. If you place a custom order for a bumper, you might have to wait several weeks for the manufacturer to build it and ship it to the dealer.

Dealers can use the money freed up by the pull system to invest in more repair shops, better diagnostic equipment, or training to enhance shop mechanic skills. Similarly, dealers can use the money saved through PDC and PRC to strengthen the company further or boost profits.

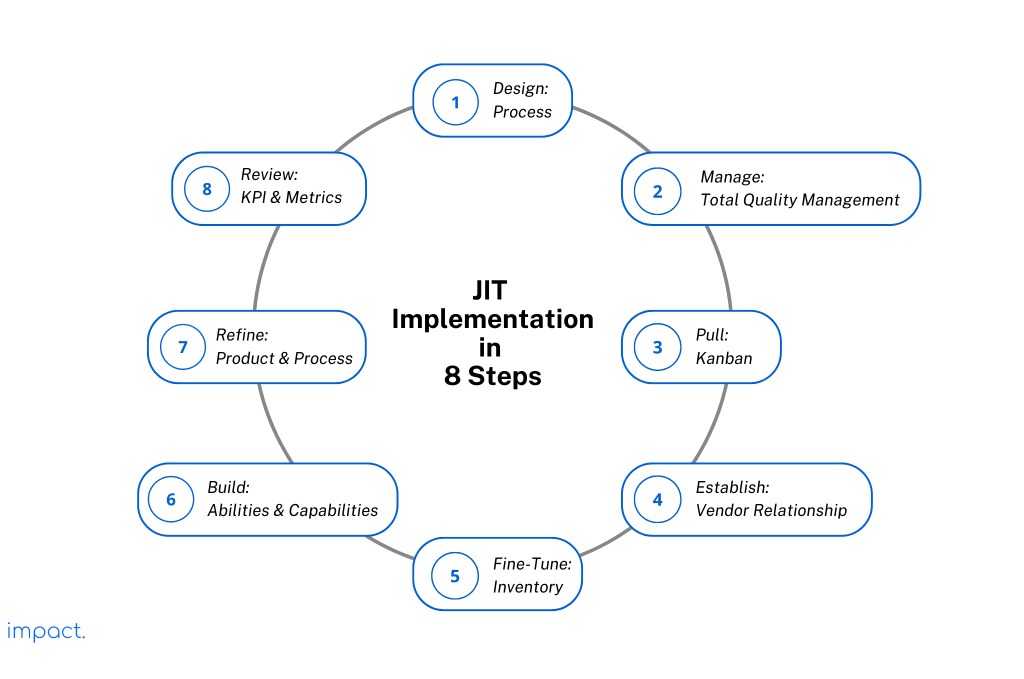

To implement a Just in Time (JIT) inventory management system for companies follow these eight steps:

Toyota’s goal with Just in Time is to ensure a smooth flow of value for customers to order their products. The critical components of a JIT system include:

Kanban and heijunka rely on the following factors:

A. Implementing standardized work is crucial for kaizen. It involves applying jidoka to minimize imperfections.

B. Capable workers are problem solvers with multiple skills and actively engage in improvement activities.

C. Capable machines utilize TPM and 5S activities to eliminate the six significant losses: equipment breakdowns, setup and adjustment delays, minor downtime, speed drops, process defects, and throughput issues.

Implementing Just in Time (JIT) in companies helps make production more efficient. However, there are downsides to using JIT. Let’s take a closer look at the benefits and drawbacks of implementing JIT:

Many big and small companies widely use the Just in Time inventory system. It’s a popular choice because it helps improve cash flow and reduce the amount of money tied up in inventory. This system is standard in manufacturing industries, such as car companies, clothing, aerospace, automotive, construction, fast food, health care, publishing, and retail.

Here are some examples of global companies that have adopted the JIT system in their business processes:

Just in Time (JIT) is a production strategy that focuses on delivering the exact amount of goods at the precise moment customers demand. The goal of implementing JIT is to ensure a continuous production flow, leading to improved company efficiency.

JIT has been successfully utilized by renowned companies like Dell and Apple, demonstrating its effectiveness in optimizing the production process.

JIT comprises various components, including Kanban and Product Leveling. The next chapter will explore these components in detail.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

This chapter will delve into another essential House of Lean Production pillar: standardization. The main focus will be on standardized work.

Standardized work comes into play once we have established stability in the production process. Achieving this stability is made possible through the implementation of 5S and TPM.

Standardized work (SW) is the cornerstone of continuous improvement, relying on consistent work processes. It reduces waste, improves work time and efficiency, and increases job satisfaction. In the following sections, we will dive into the definition, elements, charts, and benefits of standardized work.

Standardized work ensures safety, ease, and optimal performance. At Toyota, workers are responsible for designing their work, as there is no one-size-fits-all approach. Moreover, standardized work serves as a foundation for driving improvements.

Even the most efficient processes contain waste, which is why standard work is in a constant state of evolution. Regrettably, standardization has become another rigid command and control management tool in numerous organizations.

Frank and Lillian Gilbreth built upon Fred Taylor’s concept of the “single best way” and devised a method that continues to be employed by industrial engineers to this day. Industrial engineering practice relies on unspoken assumptions, namely:

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

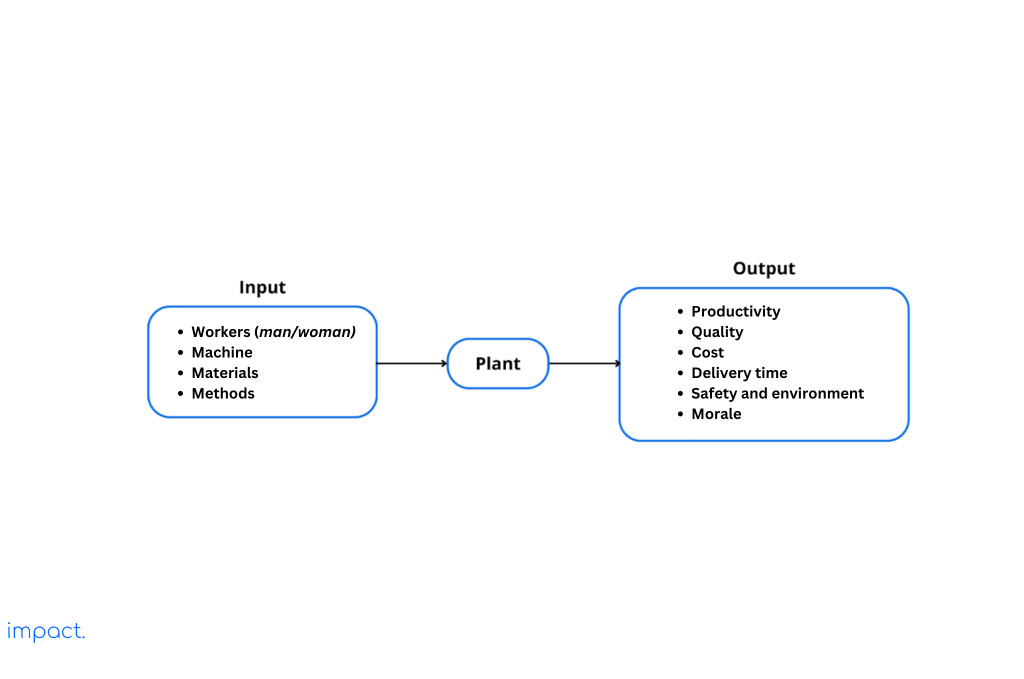

The company aims to meet the expectations of both the company and customers by providing the required output in terms of:

Standardized work is a helpful tool for creating, confirming, and improving how we do things in a company. The 4 Ms – People, Machines, Materials, and Methods – are the essential tools used in work.

People refer to the team members, Machines are the equipment like conveyors, Materials include the raw materials and parts from suppliers, and Methods represent the work process. Methods are the way workers, machines, and materials come together.

A process consists of clear goals and a sequence of steps or actions. It involves informing team members of their tasks, timing, and order. Let’s look into how this system operates within the production process:

Most companies think that the way to become more efficient is by using machines more. However, we need to understand that to make the most of devices, we have to:

This approach produces additional waste, so Toyota wants to maximize human skills. Machines provide more benefits than human flexibility. For example, an operator can:

As a result, companies favor small and straightforward machines over larger ones. They are typically more affordable, powerful, and adaptable to changing demands. For instance, if there is an increase in demand, a company can add another small machine.

Companies should focus on creating processes that prioritize the well-being of their employees and ensure smooth and safe operations. The efficiency of these processes can be measured using a metric called labor density, which is defined as follows:

| Labor density = Work ÷ Movement |

Implementing standardized work brings numerous benefits to companies. Here are some of the key advantages:

To meet standards, companies must avoid constant line stoppages and slowdowns. Here are familiar sources of instability:

To ensure machine stability, implementing 5S and TPM is crucial. Jidoka helps improve the quality, while the Just-in-Time (JIT) technique helps address spare parts shortages. Additionally, implementing 5S, TPM, and standardized work can enhance safety. Incorporating lean activities is essential for promoting stability, quality, and security.

Standardized work consists of three elements:

These elements provide a baseline for assessing a particular process during production. The following further explains each component:

Takt time is a formula that informs companies about the frequency of demand or how often we need to produce a product. Here is how to calculate takt time:

| Takt time = Daily operating time ÷ Quantity required per day |

Takt time and cycle time are distinct. Takt time is the interval between initiating one unit and commencing the next. In contrast, cycle time represents the duration needed to complete a process.

A company aims to align takt and cycle times as closely as possible. This alignment enables the integration of processes into cells, which facilitates the achievement of individual production objectives. Additionally, takt time provides a quick overview of the company’s production conditions.

The work order defines the precise sequence of tasks within a process. For instance, team members might need to follow these steps:

Clearly define each job action’s optimal method and sequence to ensure efficient job performance. Toyota uses illustrations to show:

Toyota prioritizes its people and utilizes the visual nature of standardized work as a powerful tool for enhancing safety and ergonomics.

The operator needs a minimum number of unfinished workpieces to continue working without standing at the machine. This element is called “in-process.” It’s essential because work can’t proceed without a certain quantity of goods available. Companies should increase their stock in process in the following situations:

Setting a standard for in-process stock clarifies issues and establishes the Work-in-Progress (WIP) per process.

To create standard work, team members should collaborate with engineers and other experts when needed. You can use these three different charts for this purpose:

Each chart serves as a tool to analyze and define a process while identifying areas for improvement.

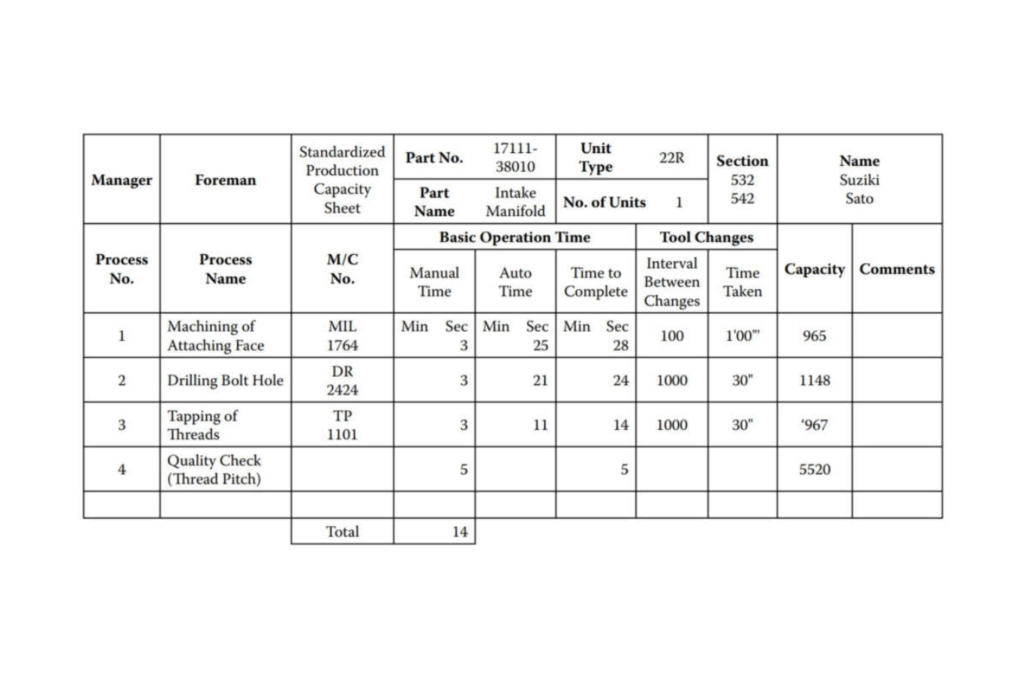

This chart determines the capacity of the machine in a process. It aids in documenting device and manual time, enabling companies to identify bottlenecks quickly. To calculate the production capacity of a specific device, use the following formula:

| Capacity = Operational time per shift ÷ (Processing time + Setup time/interval) |

Setup time is the time it takes to switch from one machine setting to another. A punch press involves changing dies, adjusting machine settings, and loading new steel coils. Conversely, interval refers to the frequency of tuning based on the number of parts.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Production Capacity Chart

The graph above shows the production capacity calculation for the drilling machine used in process 2. Here are the relevant details:

To calculate the capacity, divide 27,600 seconds by (24 + 30/1000). The result is 1,148.5 parts. Therefore, the drill machine has a power of 1,148 parts per shift.

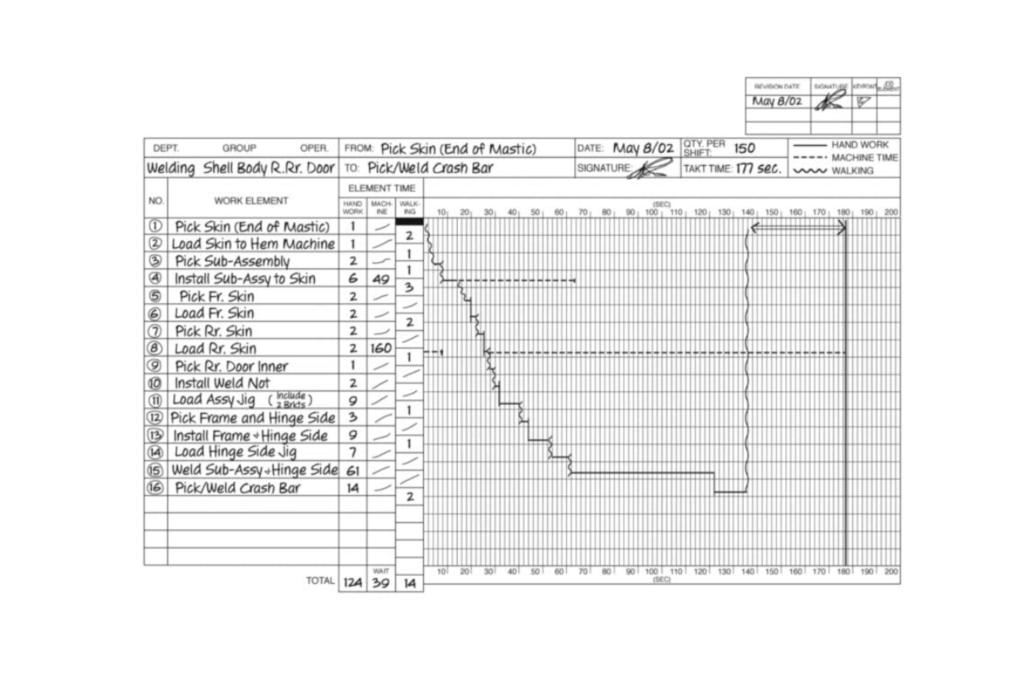

This chart presents the order of work tasks and the time needed for each job. It also shows the time spent by the operator and the machine and any interactions between the operator and the device or among different operators.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Standardized work combination table.

These charts simplify building kaizen by breaking down operator movements and connecting them to machine times.

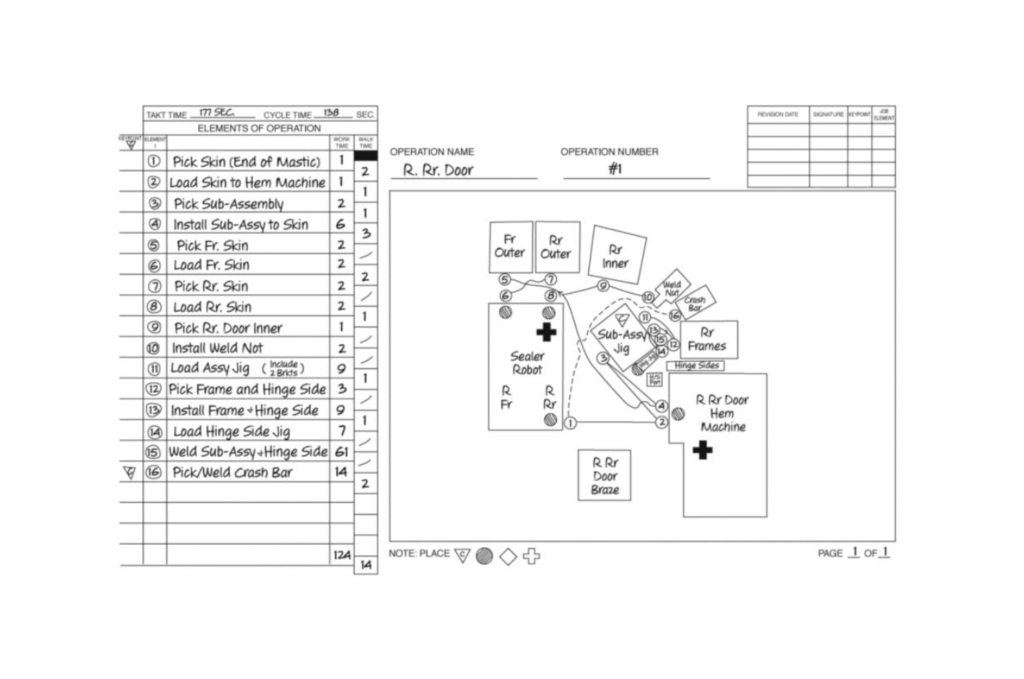

These charts serve to rationalize layouts and train workers by including the following components:

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Standard work analysis chart.

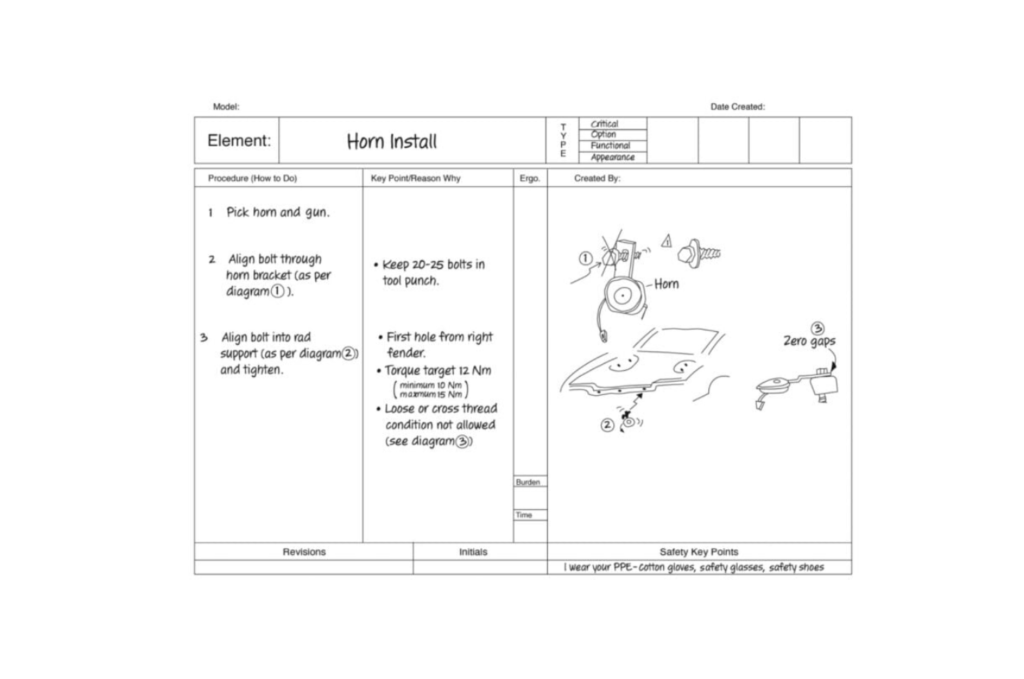

Job elements comprise the important actions or action groups needed to progress a process. The Job Element Sheet (JES) is a concise, one-page document that provides specific information, including:

Team members have accumulated valuable work records and learning points over the years, making JES an invaluable tool for recording them. JES serves as an essential intermediate step toward achieving standardized work. The image below displays the actual form of JES.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Job element sheet.

Break down the process into its elements to measure time and count each element’s start and stop times. Here are the required steps:

At Toyota, time measurement can give valuable insights into the current state of the workplace.

Standardized work tools increase efficiency by identifying the value and waste in a process. Typically, people define efficiency as:

| Efficiency = Output ÷ Labor |

At Toyota, reducing the workforce is the sole means of improving efficiency since the customer determines the results. Toyota subsequently transfers the available force resulting from these reductions. The following elements contribute to efficiency:

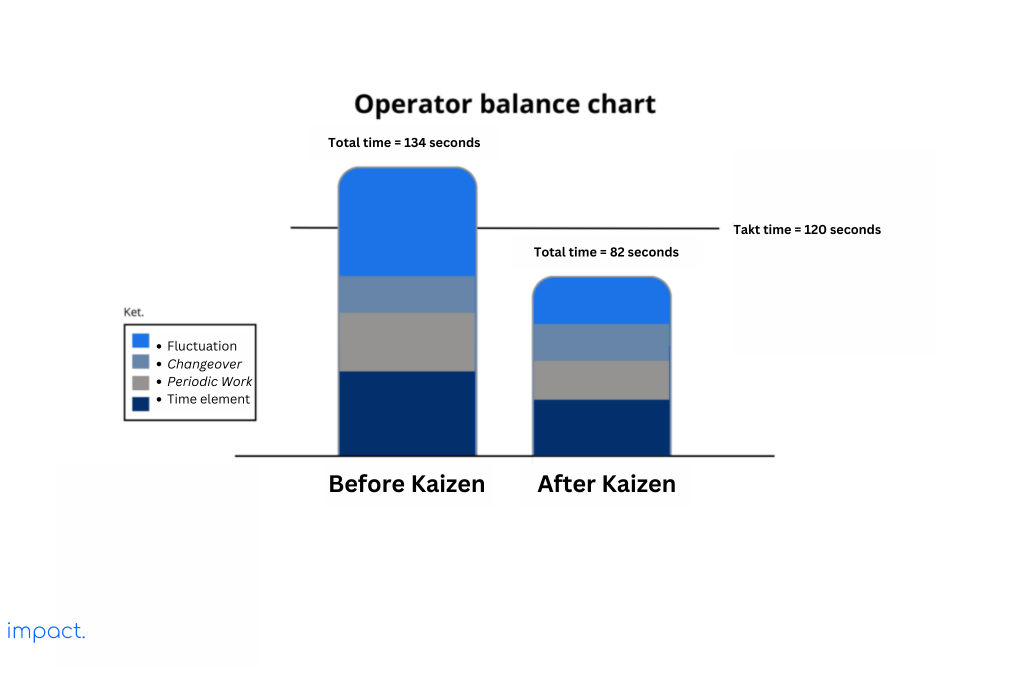

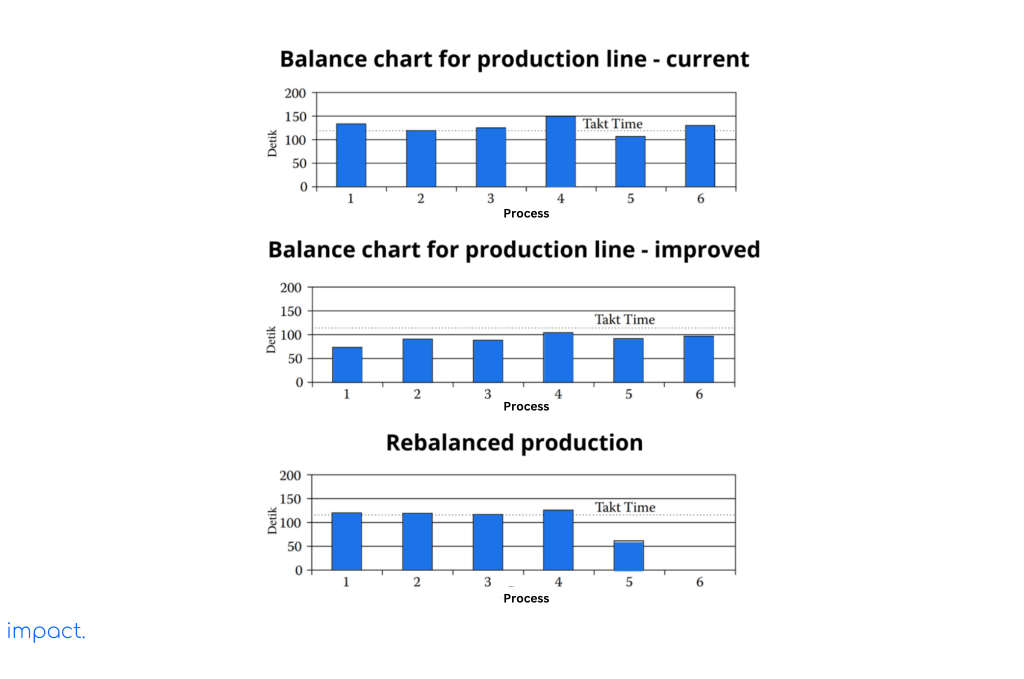

This image shows a helpful tool called an operator balance chart for pre-and post-repair processes. The improvements are due to a deep understanding of what’s happening in each process. By making changes through kaizen activity, the time for this process drops from 134 to 82 seconds. The second and third pictures display the operator balance charts for teams.

The last image shows how we can spread the work to reduce the labor needed. As you can see, we have left out process 6. Do note that processes 1 to 5 are already working at their maximum capacity, meaning they take the same amount of time as the pace of production.

However, process 5 takes up about half of the takt time. By rearranging things, we can show how long it takes to complete tasks and inspire kaizen.

| The remainder in # operatorsrequired calculation | Target |

| < .3 | Minimize wastage and incidental work. Avoid adding extra operators. |

| .3 – .5 | Evaluate whether the waste and incidental work can be eliminated after two weeks of operation and kaizen. Do not add operators. |

| > .5 | If necessary, add more operators and continue minimizing waste and incidental work to eliminate the requirement for operators. |

The image above is a guideline for determining the required number of operators.

Standardized work plays a crucial role in developing an efficient process overall. It enables us to outpace neighboring methods, resulting in a young inventory as work-in-progress builds up ahead of slower processes.

However, specific processes are inherently easier to perform than others. So, how can we foster cooperation between processes in production areas? The solution lies in designing standardized work specifically for production areas. Some key areas to focus on include:

Organizing work like this improves efficiency. The processes in a manufacturing plant rely on each other and can be affected by unpredictable changes. In “The Goal,” Eli Goldratt vividly shows the challenges faced by this kind of system:

Goldratt emphasizes the importance of identifying, exploiting, and raising bottlenecks. We can effectively reduce bottlenecks by organizing processes to encourage team members to assist each other.

Standardized work is crucial for achieving kaizen. It focuses on continuous improvement through small but sustained positive changes that can lead to significant improvements.

Failure to update standardized work can result in setbacks. It is the leader’s responsibility to uphold favorable conditions. Addressing excessive workload and irregularities (mura) becomes imperative. The following section explains these targets and their significance.

Commonly used layouts in standardized work include:

Process islands are separate from each other. Forklifts move stacks of inventory between islands. Workers in each area often focus on building quickly without considering the demand.

Conveyors or parachutes connect the islands, but there is no way to control the inventory on the conveyor. Workers typically construct as quickly as possible.

Conveyors or parachutes link the islands. Visual tools keep track of inventory between processes. The upstream process stops making more when the downstream process is already complete.

The machines are positioned side by side with minimal inventory between them. The goal is to create one section at a time. Once a piece is processed, it immediately moves to the following process. The four situations depicted in the following images illustrate this workflow.

Standardized work identifies muda and involves team members to drive development. It differs from lean production and engineering methods in its approach.

Companies can boost labor density by increasing value-added work through standardized work. The ultimate aim of standardized work is kaizen.

The next chapter will examine another pillar of the House of Lean Production — Just-in-Time (JIT). We’ll cover JIT’s definition, principles, and operations.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.