Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

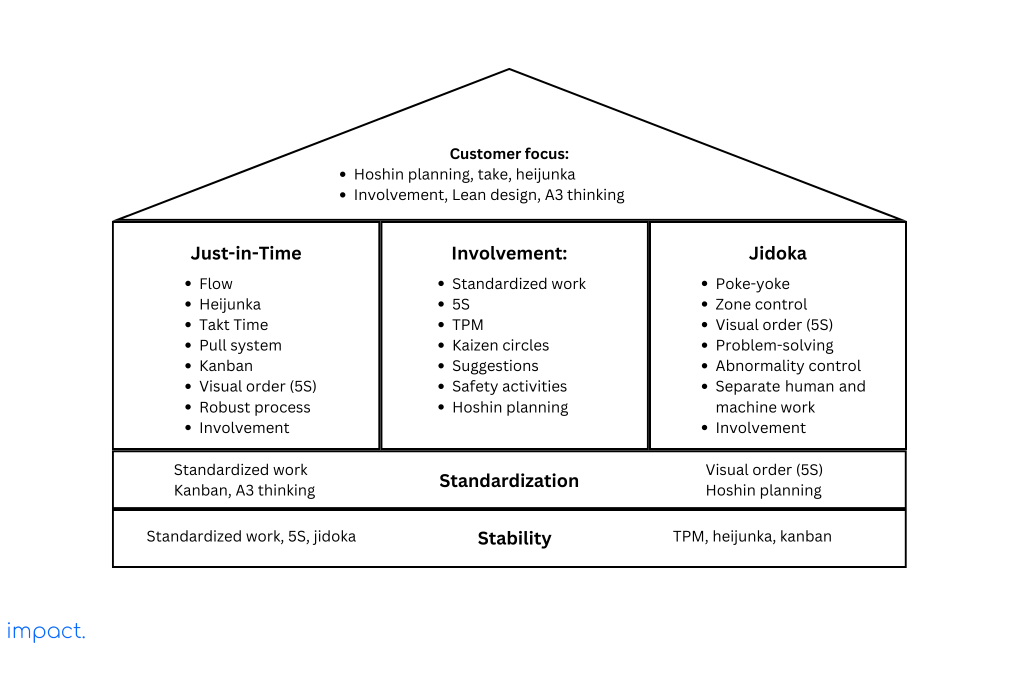

May 17, 2025Total Productive Maintenance (TPM) forms a crucial stability component that lays the foundation of the House of Lean Production. It works hand in hand with 5S, which we discussed in the previous chapter.

TPM, or Total Productive Maintenance, takes a holistic approach to equipment maintenance. Its primary objective is to achieve flawless production by eliminating breakdowns, minimizing downtime, reducing product defects, and preventing accidents.

In practice, TPM relies on visual management to facilitate training and promotion within the workplace.

Now, let’s explore TPM in greater detail and understand how it contributes to creating stability in lean manufacturing.

TPM is a maintenance approach that focuses on being proactive and preventive to ensure equipment works efficiently. When companies implement TPM, everyone in the factory is responsible for maintaining the equipment, which gets workers more involved. TPM helps increase productivity by keeping equipment running, making processes faster, and eliminating defects when used in the right environment.

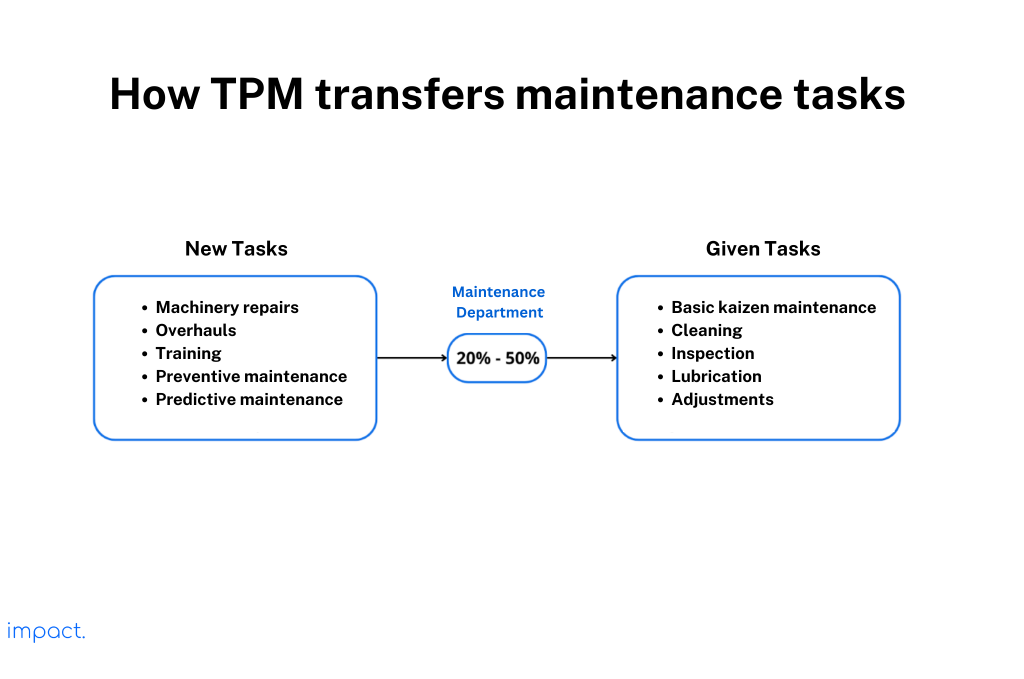

The image above shows how TPM assigns essential maintenance work to production team members, such as inspection, cleaning, lubrication, and tightening. This allocation allows maintenance team members to focus on predictive maintenance, equipment upgrades, repairs, training, and other high-value activities.

The goal of TPM is to achieve zero breakdowns. To achieve this, we take the following steps to maintain production equipment:

| TPM = (Preventive maintenance + Predictive maintenance) – total involvement |

TPM implementation relies on eight supporting pillars. These pillars primarily focus on proactive and preventive techniques to enhance equipment reliability. Here are the explanations of the TPM pillars:

| Pillar | Definition | Function |

| Autonomous Maintenance | The operator is responsible for routine maintenance tasks, including cleaning, lubrication, and inspection. | Operators have greater “ownership” of their equipment.Increases the operator’s knowledge of their equipment.Ensures the proper cleaning of equipment.Identifies emerging problems. |

| Planned Maintenance | Use predicted and measured failure rates to schedule maintenance tasks. | Reduces unplanned stop-time events significantly.Enables planned maintenance during equipment downtime.Improves control over wear-prone and failure-prone parts to reduce inventory. |

| Quality Maintenance | Detect and prevent design errors in the production process. Implement Root Cause Analysis to eliminate recurring sources of quality defects. | Target quality issues by focusing on improvement projects that directly eliminate significant sources of defects.Reduce the number of defects.Catch defects early to reduce costs and avoid unreliable inspections for defect detection. |

| Focused Improvement | Encourage small employee groups to work together proactively, aiming for regular and incremental improvements in equipment operation. | Cross-functional teams identify and resolve recurring issues.Companies combine their collective talents to create engines for continuous improvement. |

| Early Equipment Management | Utilize your knowledge and practical understanding of manufacturing equipment gained through TPM to enhance new equipment designs. | New equipment achieves planned performance levels faster, thanks to reduced startup issues.Simplified and more resilient maintenance is possible through practical reviews and employee involvement before installation. |

| Training and Education | Operators, maintenance personnel, and managers must fill knowledge gaps to achieve TPM goals. | Operators acquire skills to maintain equipment regularly and identify arising problems.Maintenance personnel are trained in proactive and preventive maintenance techniques.Managers receive training in TPM principles and employee coaching and development. |

| Safety, Health, and Environment | Maintain a safe and healthy work environment. | Enhances workplace safety by eliminating potential health and safety risks.Focused on achieving an accident-free workplace. |

| TPM in Administration | Uses TPM techniques to improve administrative functions. | Extend TPM benefits beyond the factory floor by tackling waste in administrative functions.Improve production by optimizing administrative operations such as order processing, procurement, and scheduling. |

The leading indicators of engine effectiveness include:

| Availability = (loading time – downtime)/loading time |

| Performance efficiency = (net operating time – lost time)/(net operating time) |

OEE’s creation is to help TPM initiatives by precisely tracking progress towards achieving “perfect production.

| OEE = availability × performance efficiency × quality level |

Accurate data holds great significance. However, certain managers perceive the time workers dedicate to measure machine performance as a waste. Certain companies only document equipment failure downtime if it surpasses 30 minutes.

Maintenance is all about staying focused. We need accurate records of the equipment’s operation to ensure things run smoothly. It’s not enough to know when things are down. Luckily, technology has made advancements, and we can easily access this data using ERPs.

Most companies can generate valuable data such as Mean Time to Repair (MTTR), Mean Time Between Failure (MTBF), and more with a small investment. By pinpointing hotspots, we can address the root cause of equipment problems by implementing manual processes or adding extra buffers.

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

TPM involves engaging all team members to eliminate six major disadvantages that reduce machine effectiveness. These disadvantages include:

Many companies neglect to track equipment effectiveness, resulting in an average OEE below 50%. The equipment operates at less than half of its maximum capacity.

The leading cause is crashes that result in minor downtimes, which receive little monitoring. Additionally, minor failures that don’t immediately halt operations frequently go unnoticed. One instance of this is when machines operate at lower speeds because of equipment that is worn out or dirty or insufficient debugging during the startup process.

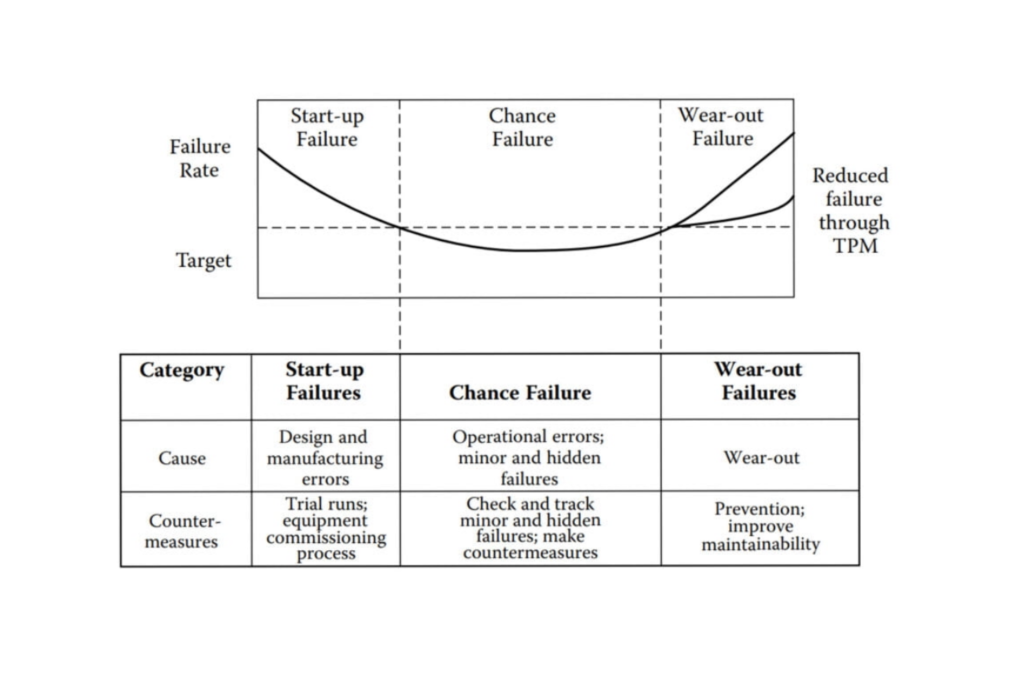

To address this issue, it is crucial to synchronize maintenance tasks with the life cycle of the equipment. The equipment’s life cycle follows the bathtub curve, as illustrated below.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; bathtub curve

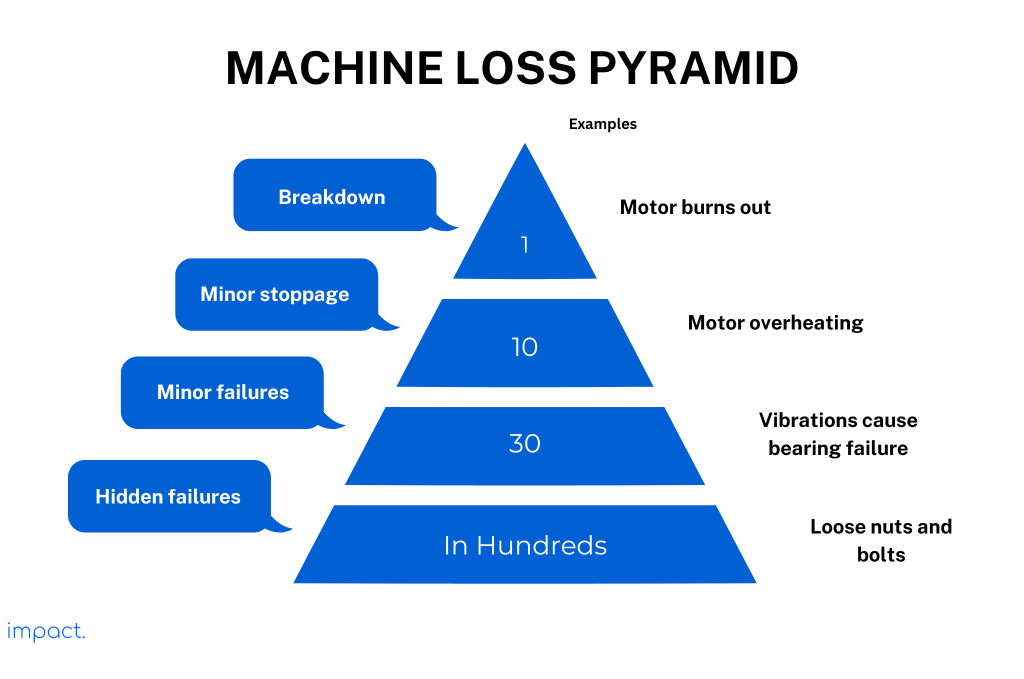

The concept of the Machine Loss Pyramid stresses the importance of spotting small, hidden losses at an early stage. Herbert Heinrich’s book, Industrial Accident Prevention, states that for each severe injury, there are ten minor injuries, 30 incidents of property damage (without personal injuries), and 600 near misses. The same idea applies to machine losses, as illustrated in the following pyramid:

What do the numbers reveal?

Noticing early signs of accidents, like minor, hidden issues, is essential for preventing damage and improving our understanding of the equipment. TPM actively pays attention to these problems and takes action before they become prominent.

Masaaki Imai talks about a production unit at the Tokai Rika plant in Japan where engineers are encouraged to report any small or hidden issues. They keep track of these problems and involve the whole team. Toyota Cambridge also does something similar: Take Action on Accident Prevention. This approach has helped them become a top leader in machine safety and effectiveness.

Involve production team members in checking, reporting, and correcting hidden failures and minor downtimes. Where possible, actively engage the production team in these tasks.

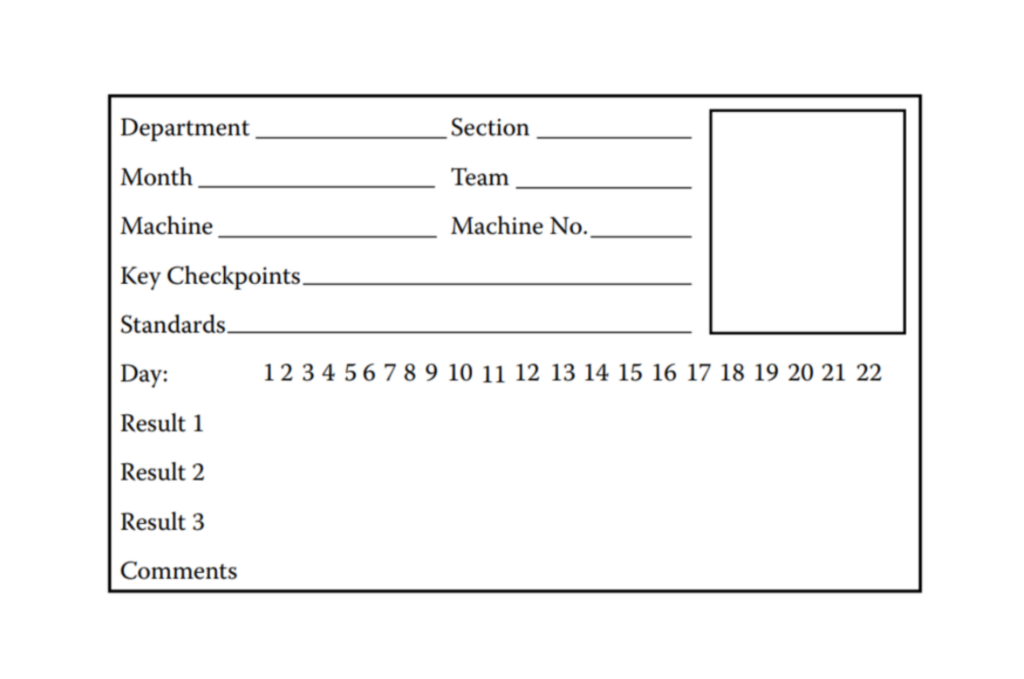

Create check sheets for each major piece of equipment and system to track and display their condition. Refer to the provided image for a generic TPM check sheet.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; TPM Checksheet.

We involve our team members in kaizen circles, practical kaizen training, and other small group activities to strengthen the identified hotspots. This approach enables us to:

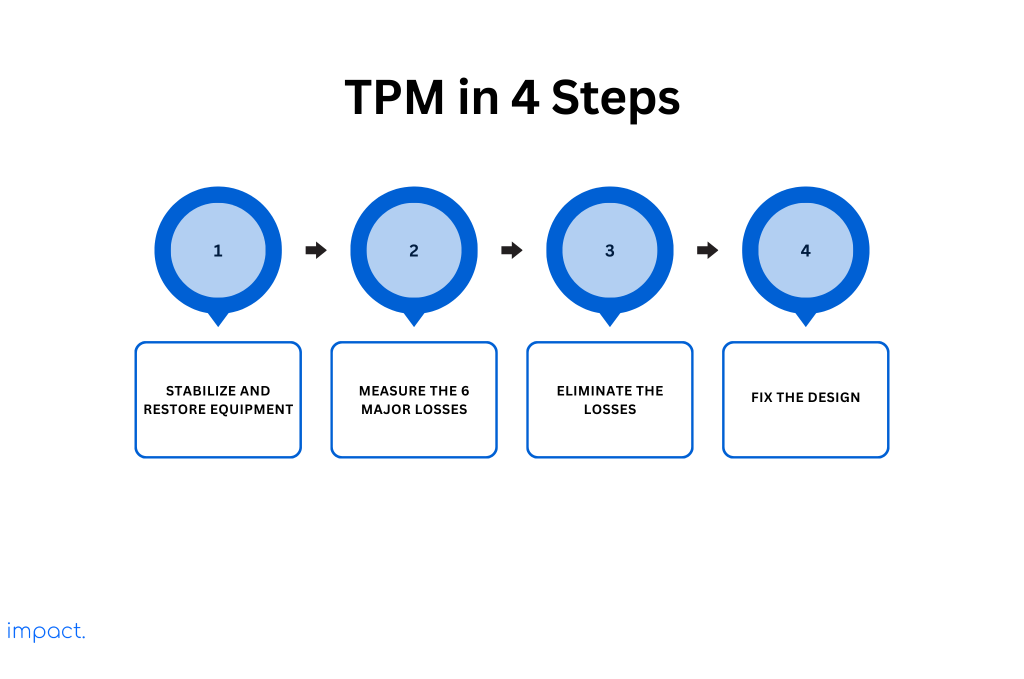

The following figure summarizes the TPM stages, from stabilizing to improving the design. These stages help streamline the production process and enhance its stability.

TPM holds the key to production stability by emphasizing proactive and preventive maintenance. Its primary goal is to maximize equipment operational efficiency and eliminate the six significant losses that hinder productivity.

Companies must actively involve employees in short-term and long-term initiatives to achieve sustainable TPM. They should establish a shared vision for the company’s future and communicate the benefits to employees. In the next chapter, we’ll explore another cornerstone of the House of Lean Production — standardized work.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

Navigating the ever-changing digital landscape can be a challenge. In this chapter of our digital marketing guide, we will explore Search Engine Marketing (SEM) and its essential role in achieving online success.

SEM offers a powerful solution for businesses looking to establish a solid online presence. It’s a vital part of digital marketing that helps you reach potential customers actively searching for what you offer.

This article aims to provide you with the knowledge and tools to succeed in SEM. We’ll cover everything from understanding how it differs from SEO, its components, and how it works. Whether you’re a business owner, a marketing professional, or simply curious, this guide is your go-to resource for effective SEM strategies.

Read more: Unlocking Growth: 19 Traction Channels for Business Success

SEM, or Search Engine Marketing, is a paid digital marketing strategy that helps your business’s products or services become more visible on search engine result pages (SERPs).

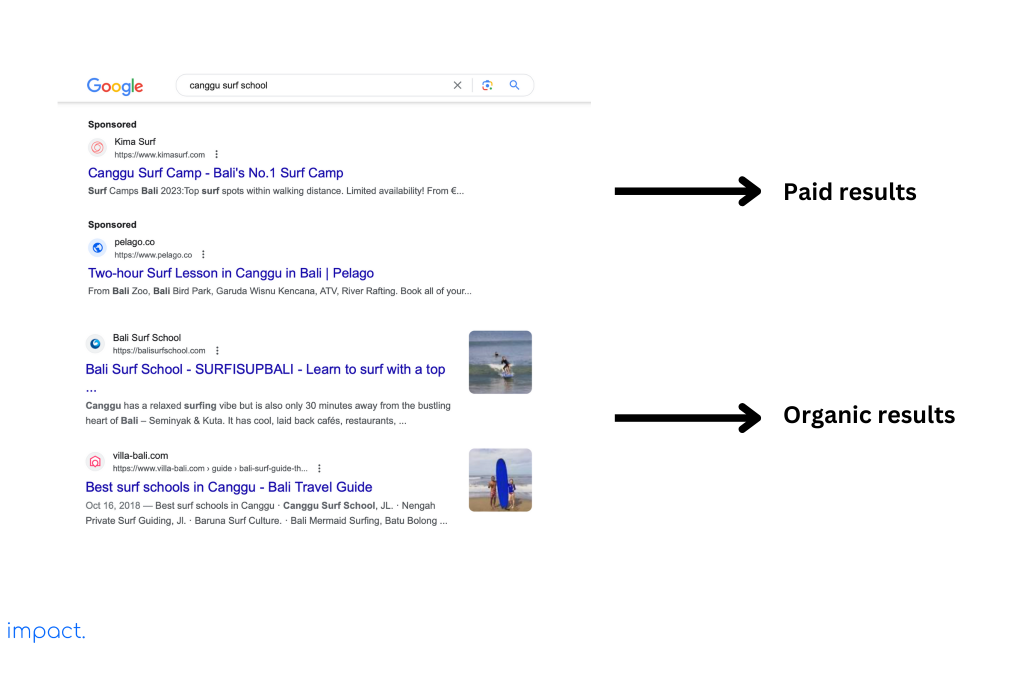

Search engines like Google display two types of results — organic and paid.

These two results differentiate SEM from SEO (Search Engine Optimization). SEO is a specific strategy that aims to improve organic rankings through optimizations and content creation. SEO is trying to gain free traffic on the internet.

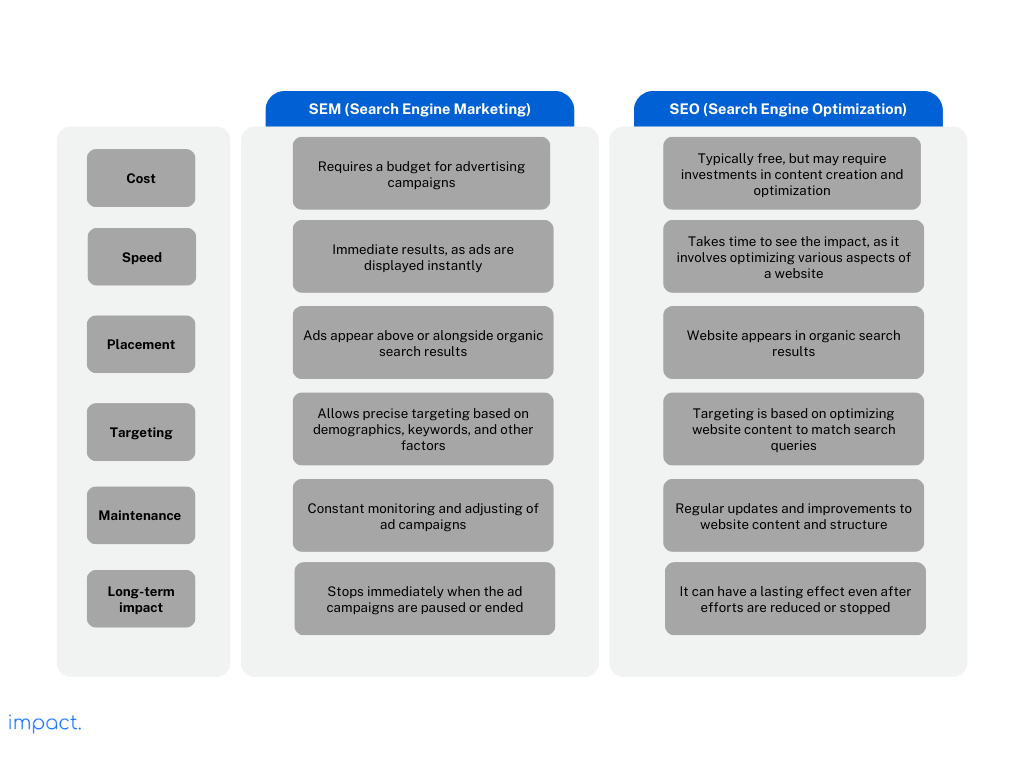

The table below tells you the main differences between SEM and SEO.

SEM enable businesses to target their audience effectively by displaying ads in search engine results pages (SERPs) when users actively search for relevant keywords, increasing the visibility and accessibility of their offerings. In addition to that, SEM offers some other advantages. Let’s look at five of them:

A business should consider using Search Engine Marketing (SEM) in the following situations:

When creating your SEM strategy, the first step is to select a platform that aligns with your business requirements. There are several options available, each with its advantages and disadvantages. Here are three examples of commonly used platforms for SEM:

Google Ads is a popular SEM platform (Search Engine Marketing). It lets advertisers show their ads on Google’s search engine results pages (SERPs), partner websites, and mobile apps.

You only need an account and a minimum budget of $10 daily to use Google Ads. You choose the keywords you want to target, and your ads will automatically appear when people search for those keywords.

The platform can be complicated, especially when figuring out your keyword strategy. However, you’ll get access to powerful tools and lots of data to help you.

Microsoft Advertising (formerly Bing Ads) allows advertisers to display ads on Bing search engine results pages and partner websites, including Yahoo. It generally has lower costs per click (CPC) compared to Google.

You can easily set up campaigns to target different time zones, which is excellent for reaching international audiences. You can customize settings for individual ad groups without changing your entire campaign.

It stands out from Google because Microsoft Advertising provides more choices for budgeting, targeting specific locations, and distributing ads across different networks. These options can help you optimize your SEM campaign effectively.

Yahoo! Gemini is Yahoo’s advertising platform for search and native ads. It combines both types of advertising in one place. Native ads are preferred for building trust and are great for inbound marketing.

Yahoo! Gemini’s native ads include content recommendation boxes and stream ads, which catch prospects’ attention. They target engaged users, making them more receptive to your content.

To choose the right SEM platform, consider the following factors:

Ranking your website higher than organic search results is an effective strategy to attract more customers and increase your revenue. So, how does Search Engine Marketing (SEM) work? As most businesses use Google, we will use it in our explanation.

When you search on Google, there’s a process determining which ads will appear and in what order. This process is called the ad auction. Whenever you search, an auction takes place to decide which ads will be displayed and where they will appear on the page.

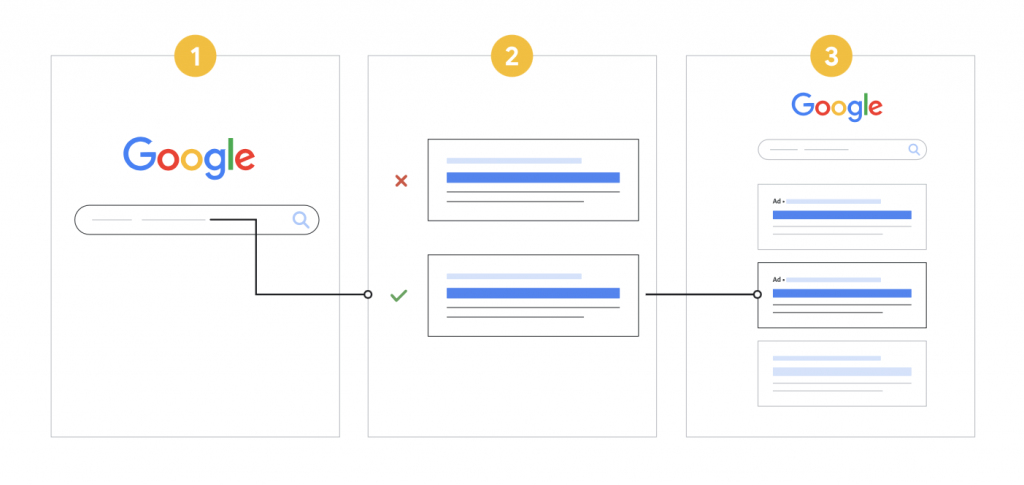

Below are three mechanics to help you understand how Google Ad Auction works:

Source: Google Ads Help: Auction

Google searches for ads that contain keywords related to a search. First, you must focus on the keywords you want to bid on and the maximum amount you will pay for each click. The cost will vary based on the industry your business belongs to.

Google’s system goes through a filtering process to eliminate ads that are not eligible. It ensures that only ads appearing on searches with significant commercial intent are displayed. Moreover, it separates advertisements that target a different country or violates Google’s policies, ensuring compliance and relevance.

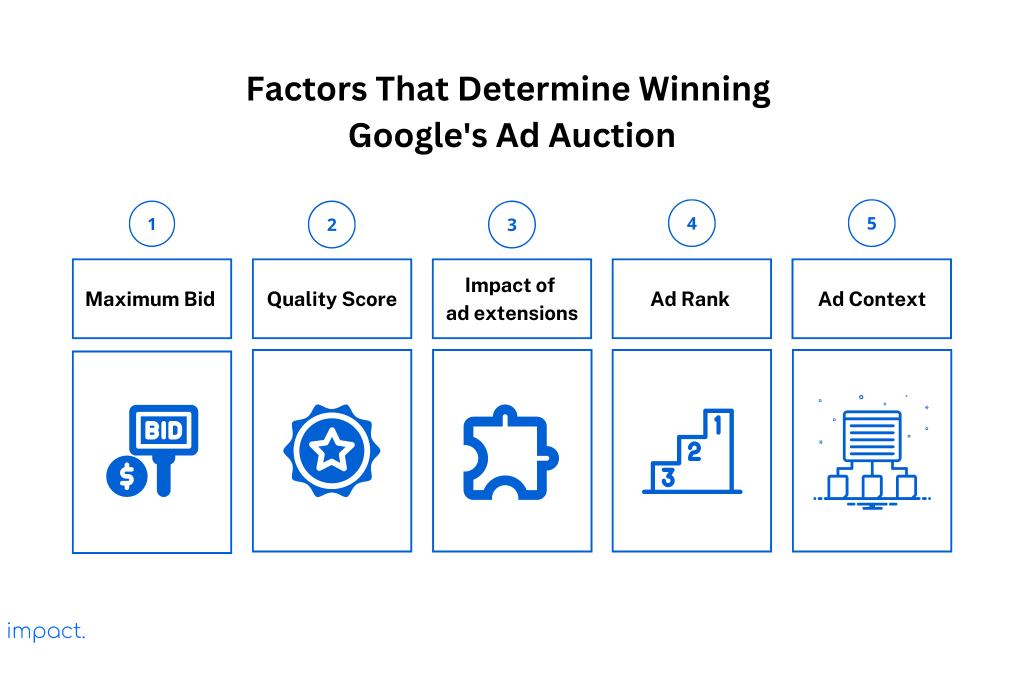

Finally, the ads appear on the search engine. The position of the search is not determined by the highest bid, like a regular auction. Winning the ad auction depends on these five factors:

Search Engine Marketing (SEM) involves various components essential for successful online advertising campaigns. Here are the key elements of SEM:

Keyword research is the foundation of SEM. It involves identifying and selecting the most relevant and effective keywords that potential customers will likely use when searching for products or services. Thorough keyword research helps optimize ad targeting and improve campaign performance.

It is crucial to create ads that grab people’s attention and make them want to click on them. These ads should be short and easy to understand and highlight what makes your products or services unique. When your ads are well-written, more people will click on them and visit your website.

A landing page is where users land after clicking on your ads. Optimizing landing pages is crucial to ensure a seamless user experience and maximize conversions. Elements such as relevant content, clear call-to-action (CTA), user-friendly design, and mobile responsiveness contribute to successful landing page optimization.

Tracking your SEM campaigns’ performance is essential to measuring success and making data-driven decisions. Performance tracking involves monitoring critical metrics like click-through, conversion, cost-per-click, and return on investment (ROI). Analytics tools provide insights into campaign performance, enabling you to optimize strategies and allocate resources effectively.

Read more: Social Media Marketing: A Guide & 3 Strategies for Success

Regarding SEM (Search Engine Marketing), following best practices is essential for the best results. By using these strategies, businesses can make their ad campaigns more effective and reach their target audience more quickly. Let’s look at some SEM best practices that can help companies get the most out of their online advertising.

When planning your SEM campaigns, it’s crucial to do thorough keyword research. It means finding the right words and phrases that match what your target audience is searching for and are relevant to your products or services. To help with this, you can use tools or platforms explicitly designed for keyword research, such as Google Keyword Planner, SEMrush, or Moz Keyword Explorer.

When conducting keyword research, thinking beyond just the apparent keywords is essential. Consider terms that may attract customers at different stages of the buying process.

For example, think about words that relate directly to your business and terms that intersect with your customers’ problems and expertise. Expanding your keyword choices allows you to reach potential customers at various stages of their decision-making journey.

A/B testing is a helpful method that compares two versions of something to see which works better. In SEM, you can use A/B testing to create different versions of your ads and landing pages.

By comparing elements like headlines, images, calls to action, or even the entire ad format, you can gather data on what your audience likes more. This data-driven approach helps you improve your campaigns by using the versions that perform best and making adjustments to your messaging and design.

SEM campaigns often follow a structured approach that uses tactics like dynamic keyword insertion (DKI) to create specific and targeted ads in large quantities. While this can be effective, it’s essential to go beyond the formula and personalize your ad campaigns for better results.

Research from McKinsey shows that personalized ads can lead to up to 30% greater efficiency in marketing spend. So, it’s worth investing time and effort into tailoring your messaging, offers, and ad formats to match the preferences and needs of your target audience.

Consider essential factors like demographics, interests, and browsing behavior to create ads that feel relevant and captivating to individual users. Personalizing your ads increases the likelihood of grabbing attention, driving more engagement, and boosting conversions.

Adaptability’s essential because things constantly change in the digital world. Monitor search engine updates, industry trends, and how people behave online.

Don’t be afraid to try new tools and technologies to improve your campaigns. Be ready to change your plans and methods as needed. By being flexible and proactive, you can stay ahead and ensure your SEM efforts continue working well, even when things constantly change.

Search engine marketing (SEM) is a continuous process that needs constant tweaking to get better results. To improve your performance:

By consistently making these adjustments based on real-time data, you can make your SEM efforts more effective and efficient.

If you want to take your business to the next level, mastering SEM is crucial. It lets you connect with your target audience when they’re actively searching for what you offer, leading to increased website traffic and improved sales.

It’s important to understand that SEM is different from SEO. While SEO focuses on improving organic rankings to gain free traffic, SEM involves ongoing monitoring, testing, and optimization to achieve optimal outcomes.

In the next chapter of our guide, we will explore content marketing, another vital component of digital marketing.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

Social media has become essential in our daily lives in today’s connected world. Over half of the world’s population, or 4.76 billion people, use social media as of the start of 2023.

We all know what social media is, but do you know how to use it effectively for marketing? It’s important to understand that using social media for personal differs significantly from using it to promote your business. That’s where our guide comes in, inspired by Jason McDonald’s helpful Social Marketing Workbook (2023).

In this article, we’ll explore the world of social media marketing and give you valuable tips and strategies to make the most of this powerful platform. Whether you’re new to social media marketing or want to improve your efforts, our guide is here to help you succeed. So, let’s dive in and discover the secrets to using social media for the success of your business.

Social media marketing (SMM), or digital marketing, uses social media platforms to promote a company’s brand, increase sales, and drive website traffic.

It enables companies to connect with existing and potential customers through social networks and information-sharing platforms.

Social media marketing also provides valuable data analytics that helps marketers track their success and discover new ways to engage with their audience.

Read more: Unlocking Growth: 19 Traction Channels for Business Success

Before we delve into how to market on social media, let’s first understand why businesses use this platform to improve their operations. Here are a few reasons why we use social media marketing:

Businesses can reach a vast audience using social media to promote their products and services. Let’s take a look at the numbers. As of the beginning of 2023, there are around 4.76 billion social media users globally. Facebook has the most significant number of users of all the platforms, with 2.89 billion as of April 2023. TikTok, a newer platform, has also gained popularity and already has a billion users.

Social media platforms are popular among the younger generation and have become integral to everyone’s lives. It’s not just limited to a specific age group or demographic. People from all walks of life have social media accounts regardless of age or background. Whether you’re a teenager, a young adult, a middle-aged individual, or even a senior citizen, you likely have a presence on social media.

One of benefits of social media marketing for businesses is it’s usually free. Social media apps don’t cost anything to use. People enjoy using them because they can connect with their friends, family, and the brands they like. From a marketing perspective, there are many things businesses can do on these platforms. They can go viral, get attention, stay relevant, and interact with the public.

Social media platforms offer many opportunities to promote your brand and connect with your audience. You can share content, run interactive campaigns, offer special deals, host live videos, and talk directly with customers through comments and messages. These activities help you show off your brand, create a community, and make customers more loyal. Using these features, you can engage with your audience and build a strong presence on social media.

In recent years, recommendation engines have emerged in social media. These algorithms work behind the scenes and suggest content to users based on their likings and preference. As users scroll through their feeds, the algorithms tailor the content they see to their interests.

Now, this is where it gets interesting for marketers. These algorithms can help marketers reach new customers by “pushing” their content toward them. It’s like a targeted approach that allows marketers to connect with people more likely to be interested in what they offer.

This technology, powered by artificial intelligence, has changed the game for brands on social media. It allows them to expand their reach and engage with a broader audience more effectively.

Let’s talk about how social media marketing works. It’s like going to a party for the people who want to buy things. When customers go to this party, they do different things and then go home. However, how they feel after leaving can be good or bad depending on the experiences.

Jason McDonald wrote a book called “Social Media Marketing Workbook.” In the book, he says marketers should perceive social media marketing as organizing a party. Here are three ways that social media marketing is similar to throwing a party:

When you plan a party, you need to promote it to ensure a successful turnout. In marketing, promotion invites customers to use or purchase your products and services. Here are what you must consider before starting your campaign.

When we organize a party, we usually take inspiration from other parties we have seen or attended. Similarly, as a marketer, you should watch what other brands are doing. Take the time to conduct competitor research, identify your target audience, and thoroughly analyze how to spread the word about your brand effectively.

As a marketer, you must have a purpose for your social media campaign. What is it that you want to achieve? Do you want to build brand equity or generate more sales?

Setting SMART goals is crucial for the success of your marketing campaign. It provides a clear framework and direction for your efforts. Without clear objectives, measuring your efforts’ impact and return on investment (ROI) becomes problematic. So, make sure your goals are Specific, Measurable, Achievable, Relevant, and Time-bound.

Picking the right platform is essential, just like choosing the perfect spot for your party. Understand the social media channels available and pick the ones that suit your brand the best. Facebook, Instagram, Twitter, and others have unique audiences and features you can use.

At a party, delicious food and entertaining activities make guests stay longer and have a great time. Similarly, in social media marketing, content plays the same role.

Content marketing is a strategic approach that creates and distributes valuable, relevant, and consistent content. The goal is to attract and retain a clearly defined audience, ultimately driving profitable customer action. Remember, the keyword here is “valuable” to your audience. Your content should address their needs, interests, and pain points.

Here are five elements to help you create more engaging content for your audience:

A buyer persona is a profile that represents your target customer. It involves creating a fictional version of your ideal customer by considering their demographics, interests, behaviors, and pain points.

This persona helps you understand who your ideal customers are, their daily lives, their challenges, and how they make decisions. It’s like a character sketch that enables you to empathize with your customers to attract better and serve them. By creating a buyer’s persona, your marketing stays centered on your targeted audience.

How often should you post content? Well, it depends on the platform you’re using. The key is to be consistent. Being consistent keeps your audience engaged and can boost your profits. Consistent brands are valued 20% higher than those with inconsistent messaging.

Find a schedule that suits you and meets your audience’s expectations. Sticking to a regular posting routine keeps your audience interested and eager for your content, whether daily, weekly, or monthly.

Stay up-to-date with the latest trends, news, and events in your industry or related to your audience’s interests to keep your audience interested. When you provide content that is timely and relevant, it builds trust and authority in the field.

However, if your content is irrelevant, it may fail to resonate with your audience. Your audience might perceive it as outdated or unrelated to current needs and interests. People may become disinterested and overlook your content.

Humans love visuals. Did you know that most people, about 65%, learn better through visual content? Pictures, videos, infographics, and illustrations can make your message more impactful.

Visuals catch our attention, help us understand the information quickly, and make content more shareable and memorable. Without relevant and eye-catching visuals, your content may not grab people’s interest or stick in their minds. So, when creating marketing content, remember the power of visuals to connect with your audience and make a lasting impression.

Emotions are powerful motivators that can drive engagement and action. Create content that taps into your audience’s emotions, whether it’s through storytelling, humor, inspiration, empathy, or nostalgia. When your content strikes an emotional chord, it becomes more memorable and encourages your audience to connect with your brand.

The purpose of your social media marketing is to get people to take action. Marketers must include a call-to-action (CTA) in their content. A CTA prompt tells your audience what action to take after seeing your content.

A CTA can take many forms. It could be to visit your website, sign up for your newsletter, buy something, share the content, or join a conversation. By adding clear and compelling CTAs, you can guide your audience toward the desired result and measure how effective your content is.

Comparing social media marketing to a party, simply sending invitations and offering food and entertainment isn’t sufficient for success. As the host, it’s your responsibility to actively engage and work towards making the party a hit.

Don’t overlook the social element of social media. Your active participation is crucial to creating a memorable customer experience as a marketer. Here’s how you can do it:

By adopting these practices, you’ll be able to better connect with your audience, ensure a smooth experience, and lay the foundation for successful social media marketing.

Now that we’ve discussed social media marketing, let’s explore the six popular platforms commonly used in this field.

Facebook is the largest social media platform with a massive user base, making it an excellent choice for social media marketing. Its dynamics encompass all aspects of social media, making it a comprehensive platform for reaching your target audience.

One of the key advantages of Facebook is its algorithm, which rewards engagement. It favors content that captivates and retains users’ attention. It assigns scores to profiles, pages, and individual pieces of content, with higher scores given to content that is engaging or even addictive.

Facebook is great for:

LinkedIn is an excellent platform for business networking because most professionals have a profile on it. You can connect with customers and prospects from different industries. It’s different from Facebook, which is more for close friends and family.

LinkedIn has a business-focused culture where people can share ideas and talk to strangers. Pitching concepts or discussing ideas with people you don’t know is not unusual.

Having a company page on LinkedIn is beneficial. You can showcase your products, services, and company culture to followers. It’s a great way to keep people updated on your latest developments.

LinkedIn is perfect for:

Read more: Using LinkedIn Marketing to Maximize Your Reach in 2024

Instagram is crucial for social media marketing and is often considered more important than Facebook. Its large user base and focus on pictures and videos make it perfect for mobile content. Instagram thrives on user-generated content (UGC), which adds authenticity and fosters a sense of community.

The platform seamlessly integrates with e-commerce, allowing businesses to showcase products, link to online stores, and drive sales. Its visual appeal enhances the shopping experience and encourages conversions.

Instagram is the perfect platform for various marketing goals:

YouTube is a platform where you can share longer videos compared to Instagram. It has many users, so you can reach many people and make your brand more visible. It’s easy for people to find and interact with your content.

You can see how well your videos are doing on YouTube using Google Analytics. It tells you how many views and time people spend watching your videos. You can also learn about your audience’s demographics and how engaged they are. This feature helps you understand your audience better and improve your marketing.

YouTube is an excellent platform for:

Read more: Developing a Successful YouTube Marketing Strategy in 2025

TikTok is a popular social media platform changing how we do marketing. It’s different from other platforms because it’s all about videos. The focus on videos lets brands show off their products and services excitingly. It’s more interesting for users and helps them remember your brand.

TikTok has a unique recommendation system that suggests videos based on users’ liking, so people spend time on the app. That means there’s a better chance for your brand’s content to be seen and liked.

TikTok is all about being relatable. That’s why it’s great for brands to grow naturally. By making authentic content, brands can connect with users personally. The platform helps build trust and makes people more loyal to the brand.

TikTok is great for:

Email marketing is a robust tool that often gets ignored compared to social media marketing. People like your product or service when they willingly sign up for your email alerts. Email is a great way to communicate directly with your audience. You can use their name and send personalized messages based on their interests or preferences.

Email marketing is a winner in getting a good return on investment. It’s affordable and can give impressive results. With a well-thought-out plan, you can get a high conversion rate without spending much money.

One of the benefits of email marketing is that it gives you measurable results. You can track how many people open your emails, click on links, and make purchases. This data helps you see your campaigns’ effectiveness and make intelligent choices for future improvements.

Here are how email marketing fits your overall social media marketing strategy:

Social media is now a crucial part of our daily lives, with over 4.76 billion people worldwide using it. However, when using social media for marketing, you need to do things differently than when you use it personally.

Earlier, we discussed how social media marketing works by comparing it to attending a party for potential customers. Just like at a party, customers do different things and leave with either a good or bad feeling. The idea of social media marketing as throwing a party emphasizes the importance of creating a positive and exciting experience for your audience.

Next, we’ll focus on Search Engine Marketing (SEM) and how it connects with social media marketing. We’ll explore how SEM can work with social media efforts to improve your digital marketing strategy.

McDonald, J. (2022, July 4). Social Media Marketing Workbook: How to Use Social Media for Business.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

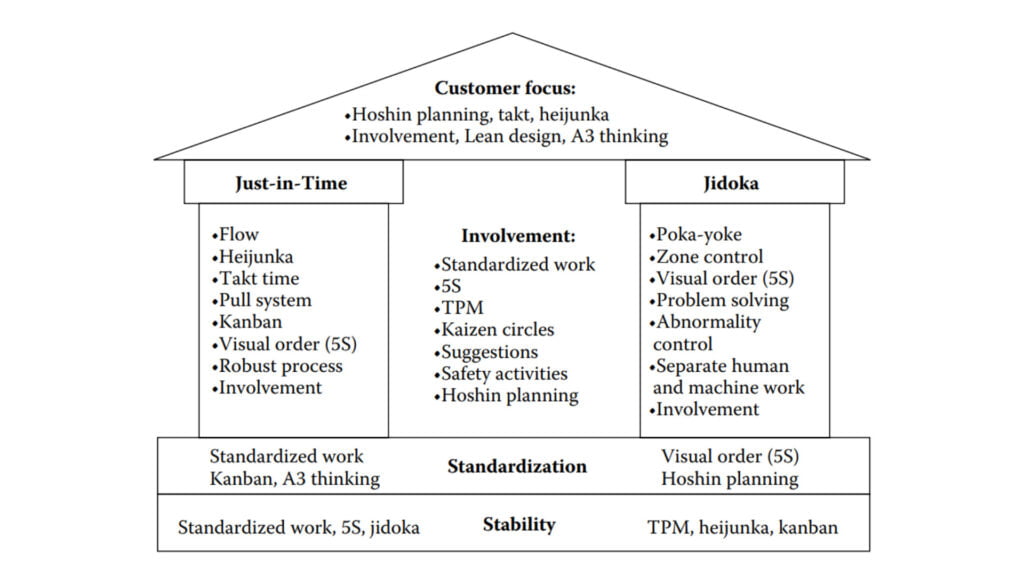

The House of Lean Production relies heavily on stability as its core foundation. Without it, achieving higher performance at Toyota is not possible.

The first step to ensure stability is to implement visual management. Several other elements reinforce it, including standardized work, 5S, Jidoka, Total Productive Maintenance (TPM), heijunka, and kanban. These various components collaborate to foster stability throughout the production process.

Source: Dennis, P. (2017); Lean Production Simplified; Basic Image of Lean Production

This article focuses on 5S and visual management in lean manufacturing, which helps create stability. Let’s dive in and learn more about them.

The production base is the standard expectation. It’s what should occur in the production process. However, Toyota sets itself apart with its distinct approach. They define standards as precise descriptions of the desired conditions.

Standards at Toyota hold great significance. They bring problems to light and motivate the company to address them promptly. Furthermore, Toyota communicates the ideal standard in a straightforward, clear, and visually apparent manner.

Toyota follows a lean manufacturing improvement process, which includes:

In a lean manufacturing system, standards directly link to actions. Let’s explore the three types and their strengths:

Read more: Lean Manufacturing: Definition & its 3 Benefits

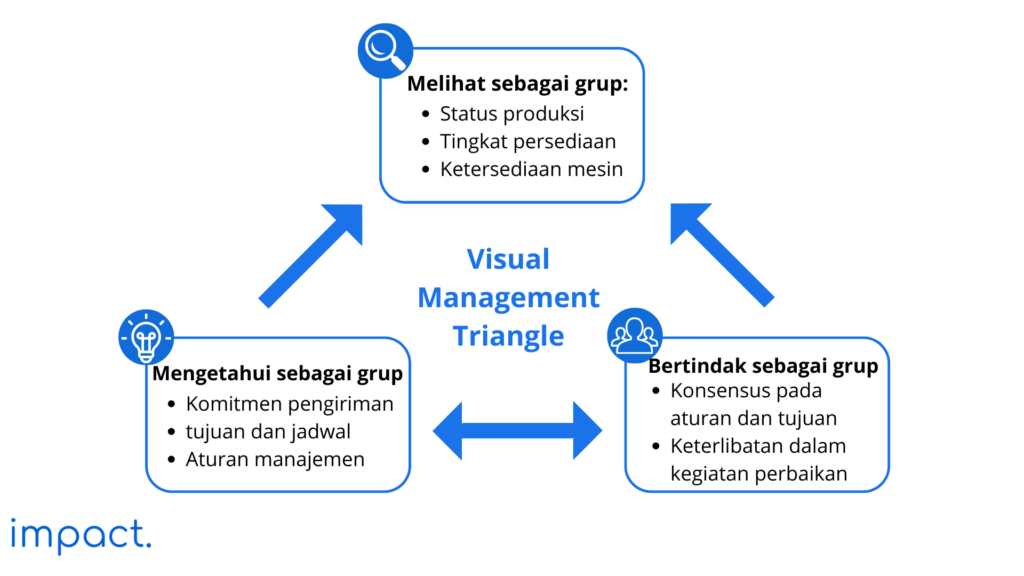

Visual management is a strategy that aims to handle exceptions and achieve excellence. It involves creating a workplace where non-standard conditions can promptly be spotted and fixed.

According to Michel Greif’s book, “The Visual Factory,” the visual management triangle is defined as follows:

The picture reveals that individuals within a group perceive actions, knowledge, and perspectives in varying ways. With their bright displays and visual representations of production and inventory, computers will become more important on the production floor.

There are four levels of visual management in application:

Many organizations limit visual management to Level 1, which involves signs that convey instructions or restrictions.

Level 2 holds more power as it can effectively capture people’s attention and awaken them to something new. A traffic light serves as an excellent example of Level 2 visual management. It signals, “The light is turning green. You may proceed with your journey.”

Having the right tools in the correct position is crucial in manufacturing. It ensures two key things: (a) availability when needed and (b) awareness when they’re not.

In manufacturing, we use poka-yokes to minimize defects in the product. We implement alarms on torque wrenches, electronic lights, and safety devices that disable engines if a team member enters the line of fire. This way, we receive timely notifications when errors occur.

The 5S system is straightforward, comprising five key components: sort (seiri), set in order (seiton), shine (seiso), standardize (seiketsu), and sustain (shitsuke). Its purpose is to facilitate visual management, creating a work environment that is self-explanatory, self-regulating, and continuously improving.

Toyota values a clean and organized workplace as the bedrock of improvement. Let’s delve into each component of the 5S system, which defines the ideal conditions at Toyota.

Sorting involves eliminating unnecessary items from the workspace to enhance production efficiency. Accumulated piles of unneeded items impede smooth workflow, increasing complexity and longer waiting times.

To sort effectively, categorize items into four distinct groups:

There are two methods you can use to simplify the elimination of unnecessary items. They are just in case management and red tagging. We will further explain them below.

Just in case management

This mindset is harmful because it ends up increasing production costs. Unnecessary items take up valuable space on shelves and floors. Even though they might have been helpful in the past, they are now outdated and never thrown away. These items make it hard for workers to find what they need.

As a result, companies need more space, racks, pallets, forklifts, and more extensive warehouses. They also need to hire more people to handle operations and management.

Red tagging

Identify your essential requirements and eliminate everything else to meet your production goals. The required method for organizing is through red tagging. Red tag labels provide crucial information about an item’s classification, ID, quantity, reason for red tagging, work component, and date.

Items not needed during sorting need to be red-tagged. Here’s the key to implementing red tagging:

Set in order is the crucial step of arranging everything in a convenient and accessible manner. The process begins only after completing the sorting phase. The main aim is to create a simple and consistent way of organizing tools, making finding and using them easier without unnecessary movement.

To streamline set-in orders, workers should initiate the process based on the tool and material usage frequency in production. Consider the following factors:

To simplify the set-in-order process, you can apply the following methods:

Rationalize location

Select a pilot area and create two maps on large sheets of paper. Depict the area’s description and potential outcomes. Outline the boundaries of the chosen location and use small sticky notes to represent the items within it (maintaining scale).

Attach the sticky notes to the map to reflect the current situation. Utilize red strings or arrows to illustrate the current movement of the matter.

Place a sizable chart beside the map and encourage team members to jot down their concerns, potential countermeasures, and comments. Allow the chart to remain for at least one week to gather feedback.

Then, create a what-could-be map using the same approach. Focus on addressing the identified hassles mentioned by the team members. Acknowledge and respond to each suggestion on the posted chart, minimizing unnecessary steps.

Finally, pick a vacant area in the plant or a parking lot. Grab some masking tape or chalk and draw out your desired layout. Use cardboard to mimic large equipment and colored chalk to indicate material movement. Once you’ve double-checked your design, it’s time to start moving the equipment.

Organize & apply color

For improved organization, align the remaining items following the three dimensions and incorporate color into the workspace. Keep in mind the fundamental principles of organizing: Where? What? How many?

Enhance workflow by rearranging equipment and parts racks. Implement a visual system, such as colored tape, to indicate the number of units, clearly displaying maximum and minimum levels or the required space. Establish consistent color standards and actively apply them in your workplace.

Ensure that everything is easily located and readily accessible. It should be effortless for anyone to find any item at any given time, and non-standard situations should be immediately apparent to everyone.

The company must effectively remove all dirt and maintain workplace cleanliness daily. Our 5S team needs to determine the following: what needs cleaning, how to clean it, who will perform the cleaning, and the level of cleanliness required.

In the 5S system, everyone is responsible for cleanliness. While the cleaning staff can still handle more extensive tasks, employees themselves should take care of the cleaning details. To cultivate this mindset, we must provide staff training and foster a corporate culture emphasizing responsibility.

Cleaning targets encompass storage areas, equipment, machineries, and their surroundings, such as hallways, windows, meeting rooms, offices, and regions under stairs. Create a comprehensive checklist detailing the specific items that require cleaning.

Determine the cleaning methods and ensure suitable equipment is available in a central area. Pack the following supplies at a minimum: broom, dustpan, hand brush, mop and bucket, duster bag, and a large trash can.

Post clear cleaning responsibilities and schedules. Incorporate a “5-minute cleanup” into every job to foster ownership and mutual respect among team members.

In addition, S3 entails equipment inspection, requiring production team members to assess their machinery’s condition regularly. They should receive training to identify minor changes in sound, smell, vibration, temperature, or any other indicators.

Develop inspection check sheets specifically for machines to facilitate these tasks. Lastly, train team members to address underlying causes of hygiene issues.

Standardization is essential for ensuring the consistent and daily implementation of the 5S concept. Clear, simple, and visual standards are critical in this process. Implementing practical solutions to recognize and resolve any uncommon situations is essential.

To establish regular habits, companies can utilize schedules and checklists. The production board, where the kanban is displayed, serves as a standard, providing information on what to create, how many to make, and the deadline.

Standardization involves three steps to ensure consistent and correct implementation of the 5S pillars:

Employees need a clear understanding of their expectations to perform their duties effectively. Therefore, explaining the steps for concisely implementing 5S is crucial. To facilitate their knowledge, we should write their responsibilities on a checklist they can easily access throughout the day.

Properly training employees is crucial to ensure the success of the 5S process. Employees who understand the process are more likely to execute it effectively.

Once you’ve taken these steps, regularly assess performance. You can form a team with employees from different departments or have department supervisors conduct evaluations. Ensure a system is in place to ensure tasks are consistently completed.

To have a successful S1 to S3 process, you must meet the following standards:

Standards for S1 to S3

The S1 standard (sort) must include the following:

The S2 standard (set in order) should include the following information:

The S3 standard (shine and inspect) should include the following:

Adopting a standardized method for assessing S5 status is essential to ensure consistency. We typically customize the 5S scorecard to align with our workplace and regular inspection schedule. Ultimately, integrating 5S into our standard work procedures is crucial.

Engagement holds the key to ensuring the sustainability of 5S as our habitual way of conducting business. Keeping our employees motivated and aligned on the right track is crucial.

To support the long-term implementation of 5S, we can adopt several approaches, such as:

Promotion & communication

Here are some ideas to promote 5S effectively:

Training

Incorporate 5S into the lean manufacturing training plan. Determine the appropriate level of training for each individual and promptly provide it. Here’s a simplified training plan:

Investing in 5S training results in quick returns. It introduces team members to the language of lean manufacturing and serves as the foundation for all future activities.

Before implementing the 5S concept in the company, it’s essential to take specific preparatory steps. These include:

Defining these concrete factors will kickstart the 5S implementation process.

Moreover, active employee involvement plays a crucial role in the success of 5S. Employees should actively demonstrate openness, willingness, and commitment to contribute to the success of 5S projects. Their active support is vital for achieving positive outcomes.

To boost employee engagement, try the following methods:

Visual management and 5S are essential foundations of lean production. Visual management has four implementation levels, from the lowest to the highest.

5S is a system that supports visual management and consists of five components: sort, set in order, shine, standardize, and sustain. Each of them has a method to make implementation easier.

To successfully implement 5S and visual management, companies should involve team members in inspecting and improving equipment. The following chapter will discuss another essential foundation of lean production called Total Productive Management (TPM).

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

Lean manufacturing is a crucial strategy for companies facing fierce manufacturing competition. In this regard, let’s delve into the meaning of lean manufacturing, its benefits, and the different types of waste it eliminates.

Lean manufacturing, also called the Toyota Production System, is a production process that aims to achieve more with less time, space, materials, machines, and human labor. Its objective is to deliver products or services that precisely meet customer needs.

The main goal of lean manufacturing is to eliminate waste and improve profitability. In the modern economy, lean manufacturing is the only effective strategy.

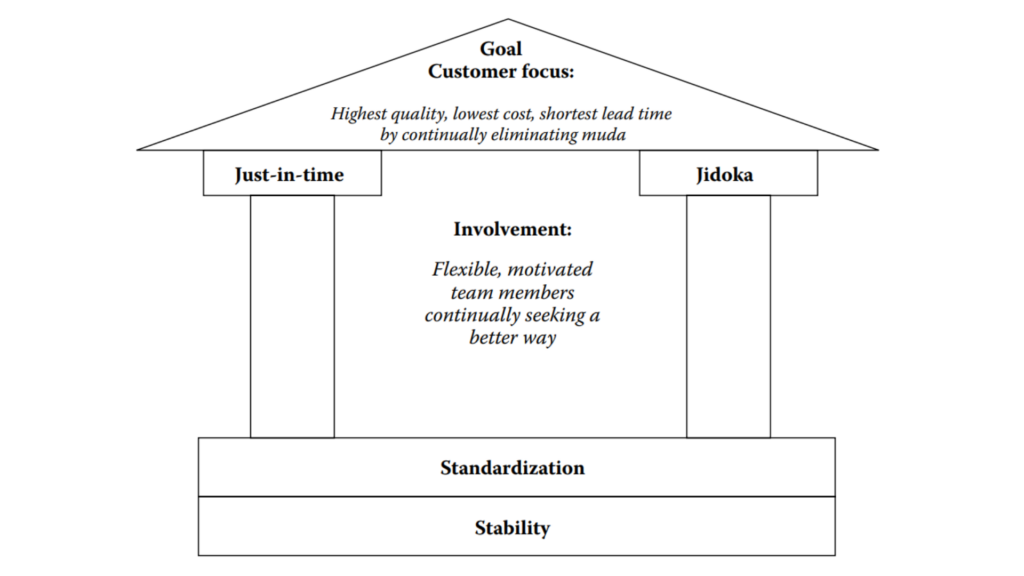

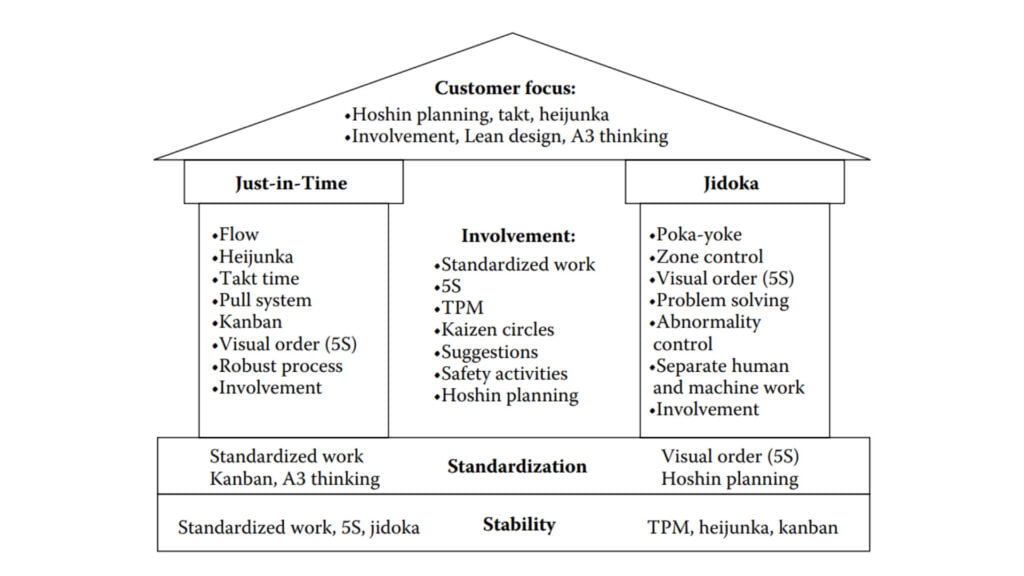

Lean manufacturing activities work together, support each other, and are guided by shared thinking. To help you better understand lean manufacturing, we can use the House of Lean Production, described below.

Source: Dennis, P. (2017); Lean production simplified; Basic Image of Lean Production

The foundation of the House of Lean is stability and standardization. Just-in-Time (JIT) delivery for parts and integrating automation with human expertise (Jidoka) represents its walls.

The system’s roof aims to prioritize customer focus by delivering high-quality products at low cost and quickly. This system centers around engagement, creating a flexible and motivating environment where each team member constantly strives to improve production methods.

At Toyota, all activities are interconnected and guided by a shared mindset. The strength of the Toyota system lies in continuously reinforcing the core concept of lean manufacturing through various activities, as shown in the figure below.

Source: Dennis, P. (2017); Lean production simplified; Basic Image of Lean Production

The Toyota Motor Company, founded in 1937, began lean manufacturing. In its early years, Toyota encountered a crisis that led to the creation of lean manufacturing principles.

In 1950, Eiji Toyoda, who started Toyota Motor Company, went to Ford’s Rouge factory in Detroit. The Rouge factory was the world’s most prominent and influential manufacturing complex.

The visit aims to understand how to enhance productivity at Ford. Upon their return to Japan, Eiji and Taiichi Ohno concluded that mass production would not be effective in Japan. They explored various alternatives to improve the production system.

Toyota faces the challenge of a small local market that needs different types of vehicles. To solve this problem, Taiichi Ohno created a system called lean manufacturing. This system helps companies with limited capital by encouraging using versatile and right-sized machines and efficient ways to switch between different vehicle types.

Furthermore, laws that prevented firing employees during that time also influenced the company’s perception of its community. As a result, this created a solid foundation for encouraging active employee participation and making it easier to solve problems together.

Ohno worked for 30 years to improve and use the lean manufacturing system at Toyota. Ohno made the Operations Management Consulting Division (OMCD) in Toyota factories and suppliers to strengthen this system. Regardless of the circumstances, this system consistently delivers positive results.

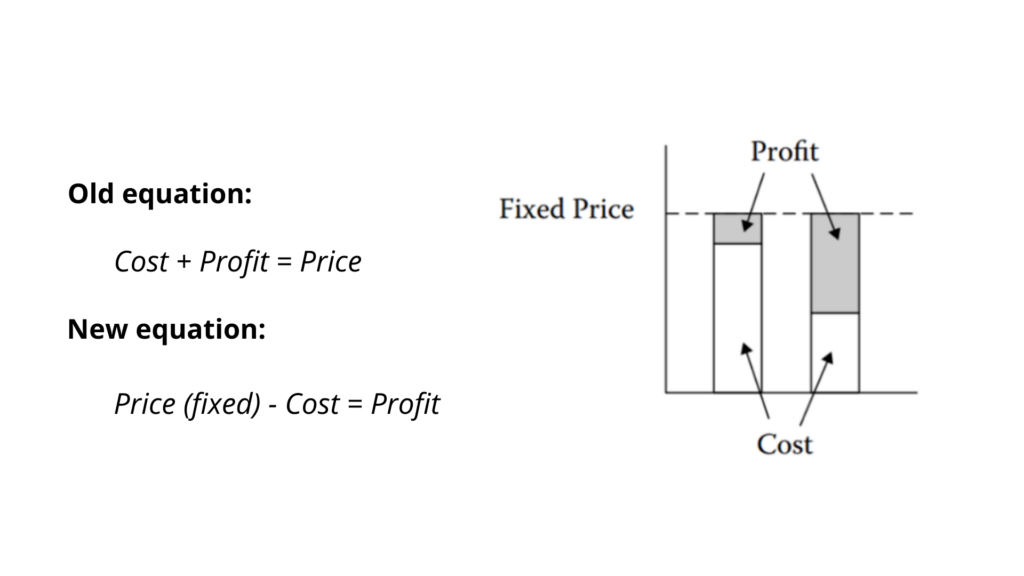

There are essentially three primary reasons for utilizing lean manufacturing, which include:

The biggest challenge of the twenty-first century isn’t just about information technology. It’s mainly about reducing costs. Now, let’s compare the old and new ways of calculating profits:

Source: Dennis, P. (2017); Lean production simplified; Basic Image of Lean Production

Can a company enhance product quality and offer customers more without cutting costs? However, cost reduction shouldn’t involve the following:

A practical cost reduction approach is actively engaging team members in improvement efforts. The Toyota system effectively minimizes waste by involving team members in enhancing corporate standards.

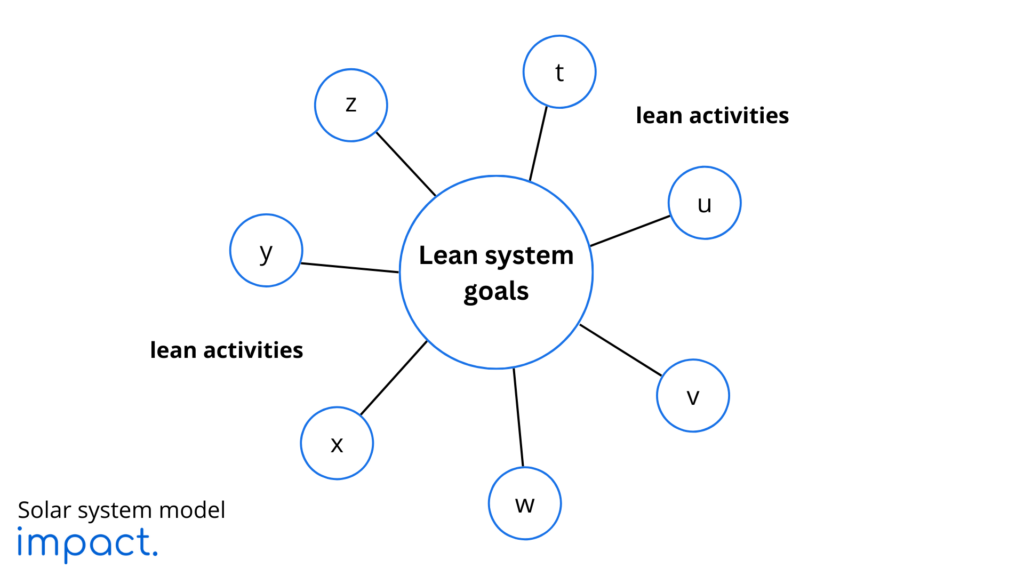

A system is a collection of interconnected parts that work together towards a specific goal. There are several critical characteristics of a system, which include:

We can understand a system better by using a solar model. In this model, the system’s goal is like the “sun” at the center, and the different activities or components of the system are like the “planets” surrounding it. The closer an action is to the “sun,” the more likely it is to help achieve the goal.

The company should focus on the most critical activities when creating this system and organize them accordingly. Keep in mind that the solar system is just an example. Establishing a practical connection between the system model and its real-life implementation is crucial for ensuring the effectiveness of the lean manufacturing system.

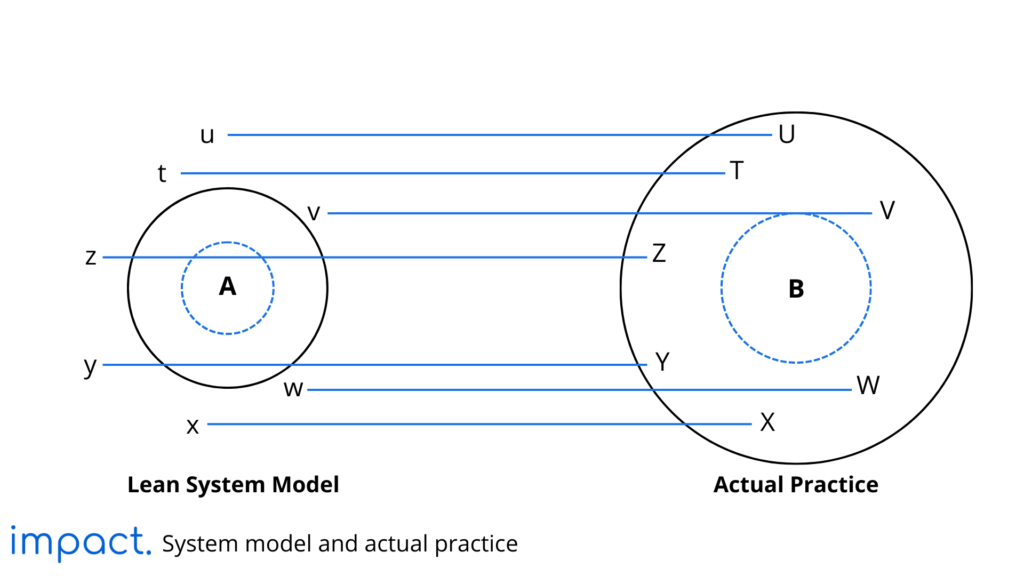

The diagram below depicts how the lean manufacturing system model relates to actual practice. Companies must transform activities labeled as tuvwxyz into actions labeled as TUVWXYZ. However, this can be challenging in a fast-paced manufacturing environment.

Once you grasp the system, system thinking is the next important idea to understand. System thinking involves thinking within a system framework and understanding how to lead a system effectively.

However, learning system thinking can be complex because people often react quickly to immediate threats. It is crucial to take the time to develop a deeper understanding of system thinking to overcome this tendency.

Lean manufacturing leaders emphasize the principle of the “thinking way.” In the manufacturing industry, implementing this thinking approach is crucial for developing the most efficient production methods.

Through promoting self-awareness and regular practice, this approach strives to enhance our thinking and foster the development of improved mental models. These mental models, shaped by our personality, upbringing, and experiences, encompass our beliefs about how things function.

When it comes to manufacturing, nine fundamental aspects highlight the contrasting mental models between lean manufacturing and conventional methods:

| Conventional | Toyota/Lean manufacturing |

| Constantly producing to meet the quota. | Stopping production to ensure it never has to stop. (Jidoka concept) |

| Producing as much and as fast as possible. (Push system) | Producing goods according to customer orders. (Pull system) |

| Produce many items at once and move them slowly through the system. (Batch and queue) | Create one item at a time and move it quickly through the system. (Flow) |

| You must do it! (Leader = boss) | What do you think? (Leader = teacher) |

| We have several standards in place. (Unclear if they’re being followed or where they’re located) | We have a simple visual for all essential things. |

| Engineers and specialists create standards. We all follow their instructions. | The closest to the job create standards and bring in specialists when necessary. |

| Cover existing problems. | Transparent in showing problems. |

| Only workers go to the shop floor. | Leaders see the shop floor themselves. |

| Do-Do-Do-Do! | Plan-Do-Check-Act (PDCA) |

There are three benefits of implementing lean manufacturing, which include:

Lean manufacturing focuses on reducing waste in materials and worker inefficiencies. There are different types of waste, such as unnecessary movement, excess inventory, waiting time, overproduction, and transportation.

To apply lean manufacturing effectively, the production staff must actively participate. The production staff observes the production process and identifies waste sources in the company. Afterward, the company evaluates these findings. When workers actively contribute to improving processes, their suggestions and ideas can be turned into practical initiatives, increasing job satisfaction.

Lean manufacturing aims to reduce waste by prioritizing loyal customers. Meeting the needs of all customers can lead to inefficiency. Building solid relationships with loyal customers increases interaction and ensures stable income.

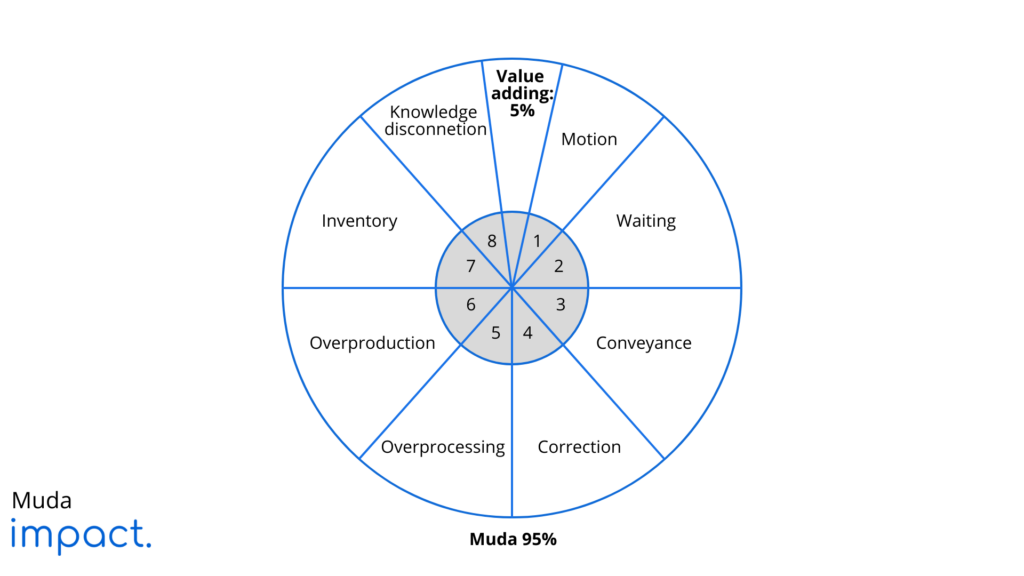

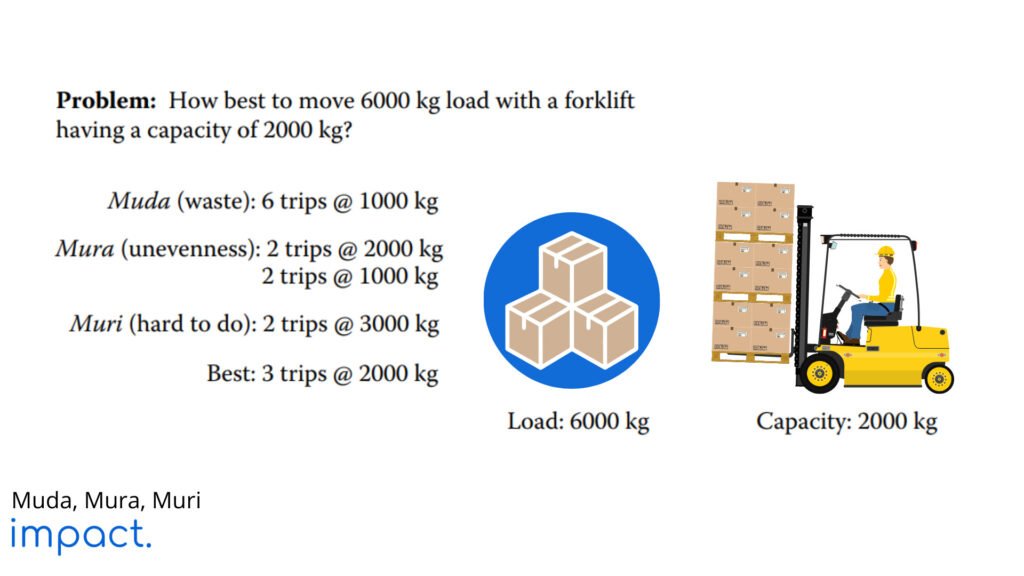

Lean manufacturing aims to eliminate waste and unproductive activities in the production process. It identifies three types of production inefficiencies: muda, mura, and muri. Let’s delve into their explanations:

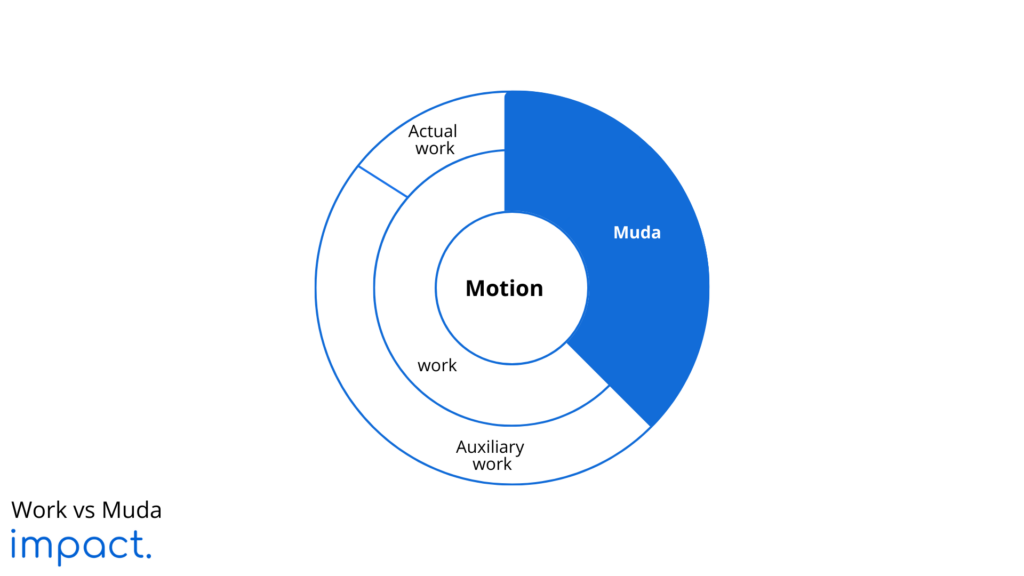

There are three main types of human motion involved in the production process:

Based on these three types of movement, with muda being the only movement, it tends to be detrimental to the company because it doesn’t generate meaningful contributions.

Muda refers to activities in production that customers aren’t willing to pay for. It is the opposite of what customers perceive as valuable, including everything they want to invest in.

In its application, muda divides into eight different types.

1. Motion/movement waste

In the workplace, motion refers to waste when humans and machines are not working efficiently together. When the ergonomic design is not good, it can cause problems with how much work gets done, the quality of the work, and how safe it is.

It is essential to focus on ergonomics to reduce the strain on people’s movements. Research shows that over half of all workplace injuries in North America happen because of ergonomic problems.

2. Delay/waiting waste

Delays or waiting waste happens when employees have to wait for materials to arrive, when a production line stops for cleaning, or when they have to wait for a machine to finish processing a part. These delays and waiting times can shorten the lead and retention times.

Lead time refers to the time it takes from when an order is received to when the customer receives the completed order. It includes the lag time and waiting time throughout the production process. To calculate the lead time, you can use the following formula:

Lead time = Processing time + Retention time

3. Conveyance/transport waste

Conveyance refers to waste when things are transported or moved around. It’s a prominent type of waste that occurs because of inefficient work setups, too big equipment, or old-fashioned ways of doing things.

Conveyance waste, delay waste, and motion waste are interconnected. This relationship arises because employees must transport raw materials to the factory to facilitate work processes.

4. Correction

Correction or repair involves fixing or repairing products that are flawed or defective. This waste includes all the materials, time, and energy used to produce and improve faulty products.

5. Overprocessing

Overprocessing is a type of waste that often goes unnoticed and occurs when production processes exceed what customers need. This particular form of waste is commonly observed in companies that engineering departments primarily run.

6. Inventory

Inventory waste typically arises from storing raw materials, spare parts, and unnecessary work in progress (WIP). This situation occurs when there are blockages in the factory’s flow and production fails to meet market demands. Companies often maintain significant inventory levels when they rely on Material Requirements Planning (MRP) for production scheduling.

7. Overproduction

This waste happens when too much is produced, leading to suboptimal sales of the final product. It results in unnecessary costs such as construction, maintenance, extra parts, raw materials, labor, and energy. This waste also triggers additional types of refuse like motion, waiting, conveyance, correction, and inventory.

8. Knowledge disconnection/miscommunication

This kind of waste happens when there are misunderstandings or a lack of communication within the company. For instance, it can occur between the company and its customers or suppliers. Such situations can block the smooth exchange of knowledge, ideas, and creativity, leading to frustration and missed opportunities for the company.

Mura refers to unevenness or variations in work, often caused by frequent changes in production plans. The goal of the lean manufacturing system is to minimize mura by using a technique called heijunka or product leveling. This technique involves mixing different models on the production line.

For instance, let’s consider a scenario where a production line manufactures a complex model for half of the shift and a simpler model for the remaining half. In such cases, an employee may work intensively on the complex model for half of the day and then switch to the simpler model for the other half.

Muri is a term used to describe challenging work. Muri may result from inconsistent production, inefficient work procedures, uncomfortable or ill-fitting equipment, inadequate tools, and vague instructions. To address muri, the company must assess and improve equipment or product design plans through evaluation.

Implementing lean manufacturing is an effective strategy for cutting waste and boosting company profits. The House of Lean Production provides a straightforward approach to comprehending the practical application of lean manufacturing.

This system targets eight types of waste, known as muda, while also addressing related concepts of mura and muri. Additionally, it enhances positive relationships with both employees and customers. The upcoming chapter will delve further into House of Lean Production’s fundamental aspect – stability.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.