Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

May 17, 2025Picking is when we take the items customers order from the warehouse shelves and send them out. It’s one of the most expensive parts of the warehouse process.

Picking has its challenges. It’s hard to automate, needs careful planning, and mistakes can happen quickly. Most importantly, it affects customer service directly. Despite these challenges, managers want to increase productivity in picking to reduce warehouse costs. They must consider the trade-offs between speed, price, and accuracy.

In the past 20 years, there has been a shift in order taking. Previously, we would gather items in large quantities. However, nowadays, it is more common to pick smaller amounts and have deliveries occur more frequently. Concepts such as Just in Time, the rise of online shopping, and the desire for shorter waiting times have driven this change.

We’ve talked about warehouse management before. This article focuses on picking orders and explaining them in more detail.

The 2009 Benchmarking Survey showed that Aberdeen Group uses specific measures to identify the best picking operations. They present the data in the table below:

| Metrics | Best Practices | Industry Average | Delays |

| Percentage of accurately picked orders | 99.8% | 97.7% | 88.4% |

| Percentage of orders delivered on time and as expected | 99.5% | 95.6% | 88.2% |

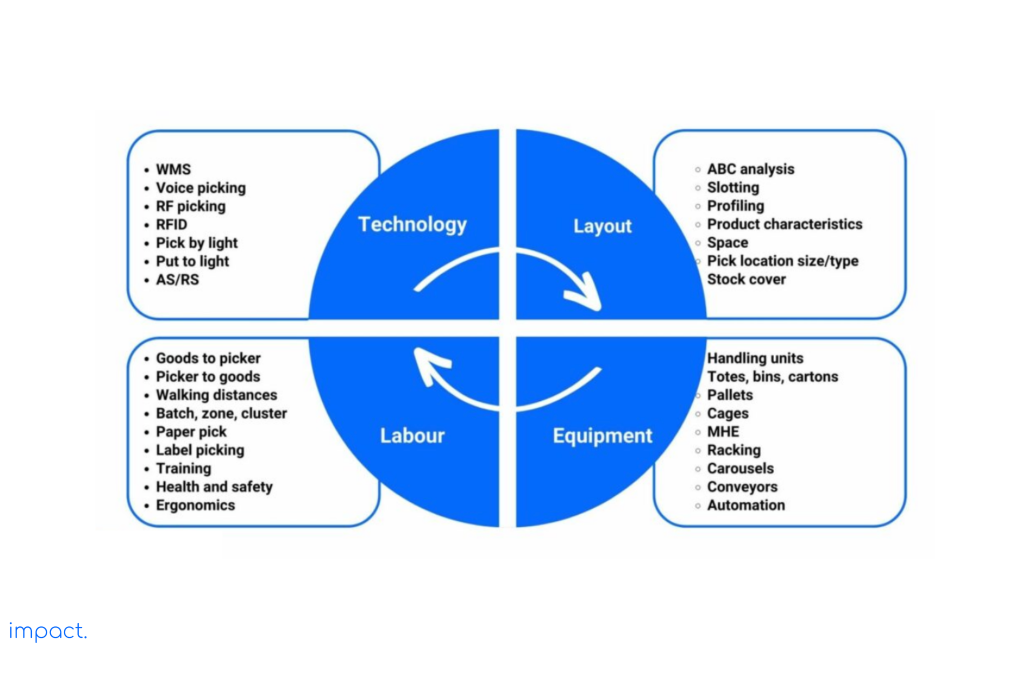

The figure below illustrates how labor, technology, equipment, and warehouse layout interrelate.

Moving between different picking spots is one of the most significant expenses in the picking process. Depending on the method, these charges can account for up to 60% of the time required to complete the picking process. That’s why managers need to choose the right way to do the picking based on the conditions in the warehouse to reduce these costs.

Read also: Warehouse Manager: Roles and 10 Challenges to Overcome

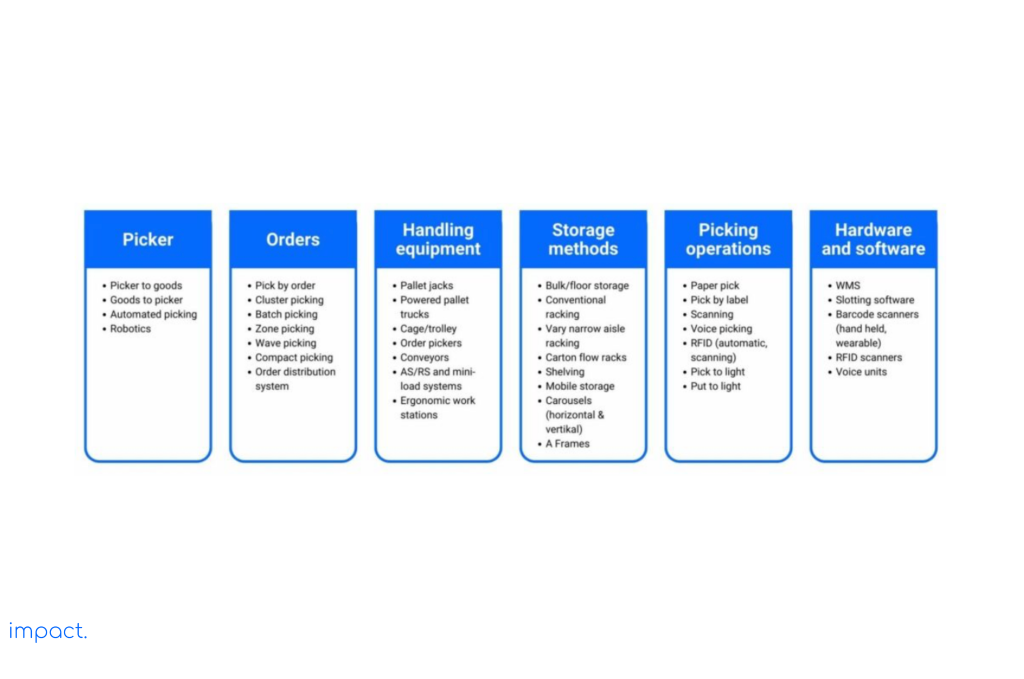

We use various strategies to handle orders, pick items, and determine the necessary equipment in the picking process. The picture below illustrates the methods and tools utilized in the picking process. We will delve deeper into this topic in the following article.

A little preparation can go a long way when it comes to getting your warehouse ready for efficient picking. Setting up the proper layout and organizing your space can streamline the picking process and save valuable time.

According to Frazelle (2002), only around 15% of SKUs are inefficient locations, which leads to higher costs due to increased travel time and unused spaces. To avoid this, you can take some steps before picking items. Start by using the right equipment, setting up a storage system, deciding on a picking method, and conducting an ABC inventory analysis.

Pareto’s Law, or the 80/20 rule, explains the ABC classification. This rule states that:

ABC classification is a way of organizing goods based on their importance using Pareto’s Law. Different companies and market sectors may have their classifications. When it comes to sales, here’s how ABC classification works:

Many companies use ABC analysis to optimize their warehouse layout effectively. Relying solely on traditional ABC analysis has limitations. It only provides a snapshot of the situation based solely on sales levels. As a result, relying exclusively on this analysis can reduce productivity.

Let’s look at an example that compares two products over a specific period using only ABC analysis:

| Product | Sales | Orders |

| Product A | 10,000 units | 4 |

| Product B | 1,000 units | 200 |

Although Product A achieved the highest sales, it received only four selections during that period. In contrast, Product B, despite having lower sales, received 200 orders. This data indicates that Product B demonstrates faster movement and warrants placement near the dispatch bay.

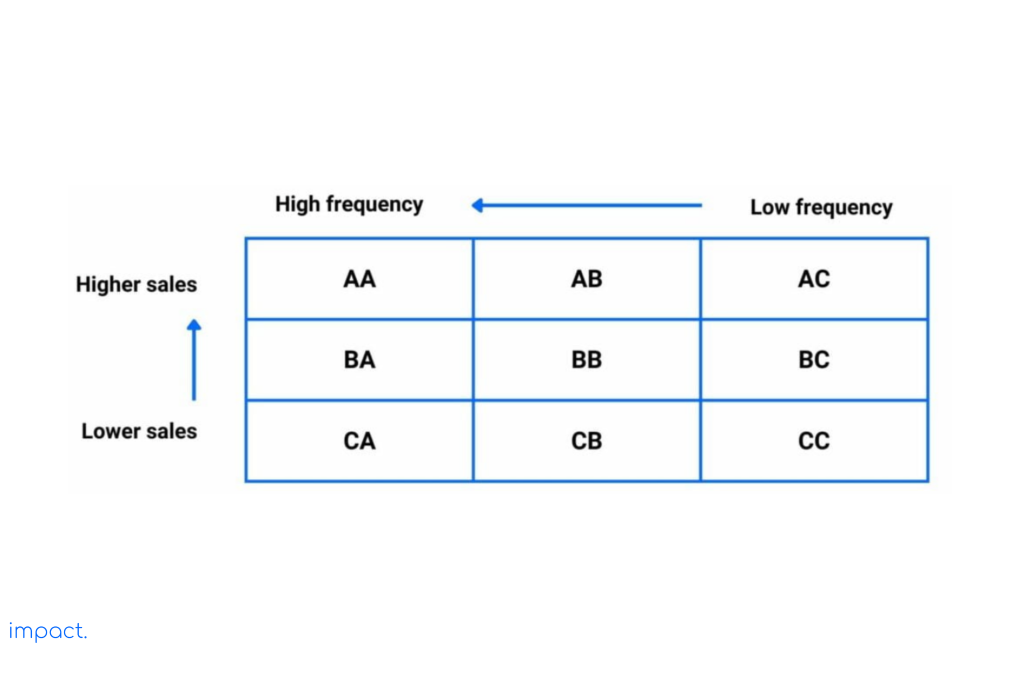

Right now, we have a system called dual ABC classification that combines two categories: volume and frequency. This system helps us create a nine-box lattice, like the one in the picture below.

The figure reveals that AA products have the highest sales and frequent customer purchases. In contrast, CC products have the slowest sales rate. When you visit the picking location more frequently, the number of people present increases. Despite making up only 8% of the product suite, AA products contribute approximately 50% of the total sales.

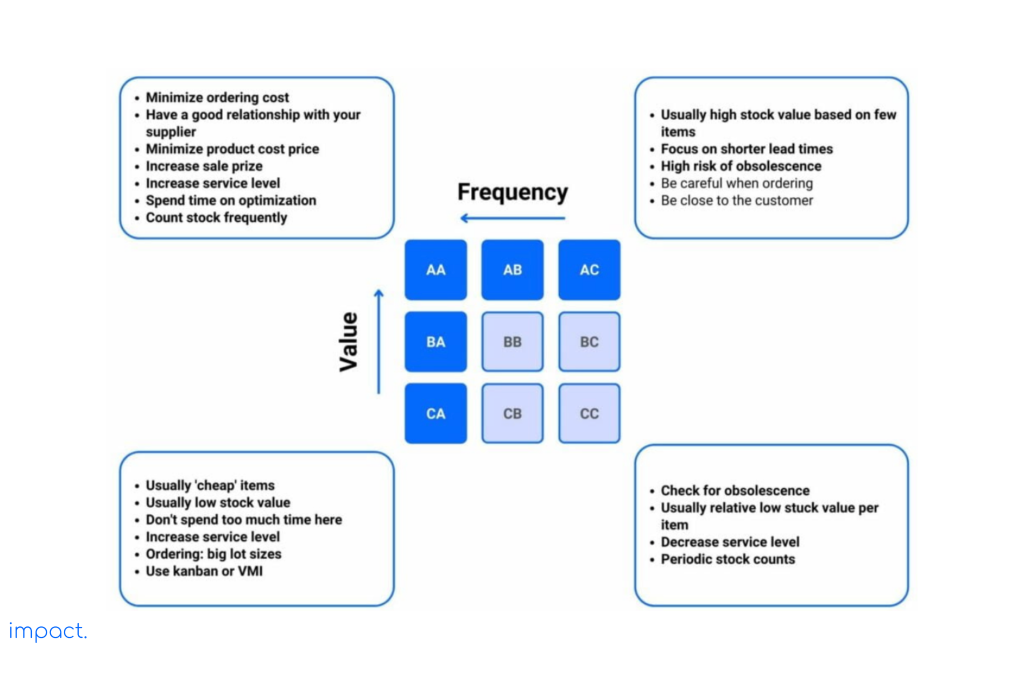

The figure below explains the connection between how often a product sells and its value. It suggests that each sector requires a different approach. The strategy you choose can depend on the level of service, how often and how you order stock, how often you count your inventory, and the relationship between you and your customers and suppliers.

To make your warehouse more efficient, consider a few things.

First, calculate the weighted volume by multiplying the annual demand by the number of products on the shortlist. This calculation helps ensure that you don’t end up with too many products causing delays in the delivery area.

Remember that the more often you visit the pick face, the higher your labor costs will be. Traveling during picking can make up a significant portion of the total picking time. That’s why arranging your warehouse layout is essential based on the number of pick-face visits needed.

Another critical factor is slotting, which determines the best location for each product in the warehouse. It’s not just about placing fast-moving items near the delivery area. It’s also about grouping frequently shipped products together in the pick-face area. This way, you can reduce travel time and make picking more efficient.

Slotting can also help you determine how many pick faces you need for each product line and what size they should be. It’s a good idea to spread high-demand products across the front of the racking closest to the start and end of the picking run. Slotting prevents congestion and keeps things running smoothly.

Additionally, your system can identify small batches of products that can fulfill large orders. By looking at which items are popular and combining that with completed orders, you can allocate a specific area for those products. Slotting can also consider seasonal changes and suggest moving certain products during different times of the year.

This system can calculate other parameters and help determine the collection method by profiling goods and orders. It also facilitates the preparation and storage of products by strategically placing popular items in easily accessible locations.

Calculating the lines per order allows for the analysis of orders. It helps determine the number of orders per product code and the necessary pick-up locations. When a substantial number of items are on a single line, it is crucial to differentiate between standard and backorders. For standard charges, the appropriate method is the batch pick.

When picking goods, they are placed in smaller containers and combined in a designated area. The Cube per Order Index (COI) is a strategy that calculates the ratio of product line space requirements to the number of daily picks. This ratio helps determine the position of the picking run, with lower COI, indicating better utilization of product space.

Combining these factors enables us to determine the most suitable picking method for the warehouse. We can pick up small cube orders using roll cages or trolleys, while larger ones require trucks or pallet jacks.

By analyzing demand variations, we can determine the pick face size and the quantity to hold for each product type. This analysis ensures we maintain an adequate stock level to meet a day’s demand and reduce refills’ frequency. Calculating the average daily direction and standard deviation allows us to obtain demand figures for each item.

Ensuring sufficient space in the picking area is crucial to accommodate the required stock quantities is vital. The space calculation considers the total warehouse capacity, floor area, and reserve stock storage requirements.

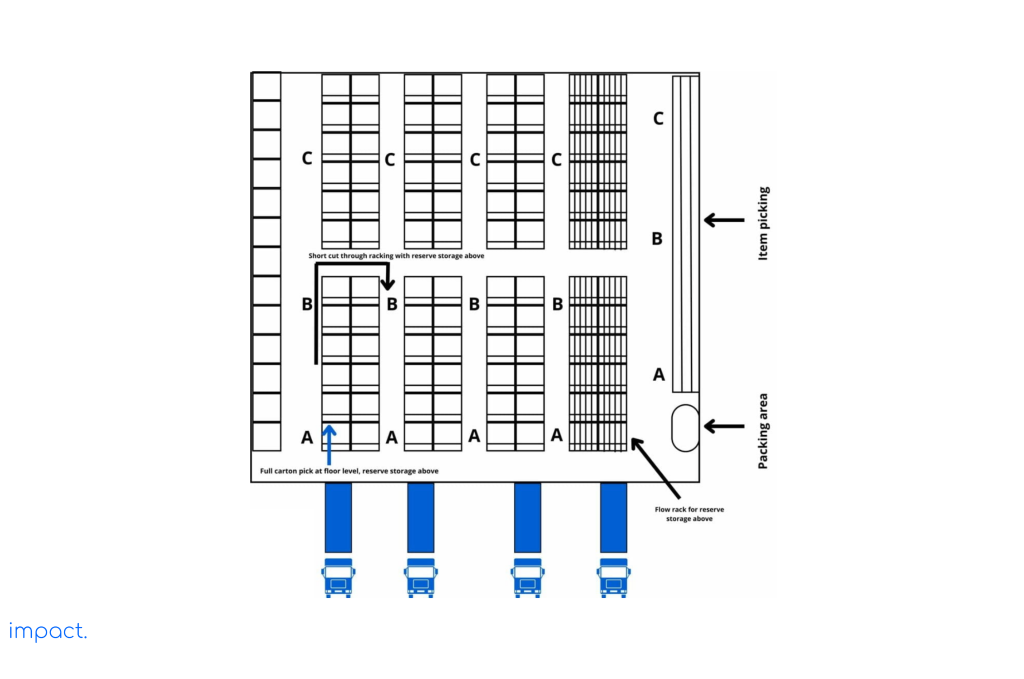

Take a look at the image below. It shows a simple layout that uses ABC analysis from a pick-face visit. To make the warehouse run better, we need to minimize the number of trips when picking orders.

When choosing picker routes for order preparation, consider the following:

Warehouse layouts typically include racks or freestanding storage areas for spare pallets. The positioning of these storage areas depends on the number of different products and the available floor space. It is vital to avoid having pickers retrieve full pallets from the picking area since they require replacement.

Creating a separate area in the warehouse specifically for these product parts is more cost-effective when multiple orders require them. This approach simplifies picking individual items, especially when small quantities are needed, and provides a designated space for storing unused items.

To improve the picking process:

When planning the warehouse layout, thinking about the space needed for other services like labeling, packaging, and packing things together is essential. That area should be near where items are picked and delivered to avoid long trips. It’s also necessary to think about the people working in the warehouse and choose equipment and work areas that are safe and comfortable for them.

To figure out the best picking system, you’ll need the following information:

Once you’ve gathered this data during profiling, you can choose the most effective retrieval system.

We must make essential preparations to ensure an efficient and productive picking process. These preparations involve understanding the products and sales patterns and using available data to analyze them using ABC analysis.

By placing the products in the right spots, we can reduce the distance the operator needs to travel and make their job less stressful. This method will increase productivity and save money overall. So, we have to consider how to arrange the warehouse layout carefully.

The next chapter will discuss the picking process in more detail.

Aberdeen Group. 2009b. Warehouse Operations: Increase Responsiveness through Automation. Boston: Aberdeen Group

Richard G. 2011. Warehouse Management. Great Britain: Kogan Page Limited.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.