Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

May 17, 2025Warehouse managers need to be good at running things to make warehouses work better and get more done. They must find ways to make things faster, save money, keep customers happy, and ensure everyone stays safe. That’s why managers need to know all about the different jobs in the warehouse and how they affect the whole business and supply chain.

This article is a continuation of the previous chapter. It talks more about what managers do in warehouses and what problems they might face. It discusses the challenges they will face and the critical qualities they must possess.

These days, warehouse managers spend more time in front of laptops than manually patrolling warehouses. They use laptops to find the latest solutions for cost and productivity.

The job description for a distribution center manager now requires the following skills:

The warehouse manager’s primary responsibilities include:

The job description above outlines the typical expectations for a warehouse manager in today’s fast-paced business environment. This description aims for managers to provide excellent customer service while finding ways to save money by increasing productivity and performance.

Additionally, managers should effectively manage inventory and prioritize the safety and security of their staff, equipment, and stock. To fulfill these responsibilities, warehouse managers must make trade-offs and actively handle various aspects of the job.

To effectively manage a warehouse, it is crucial to adhere to the following fundamental principles:

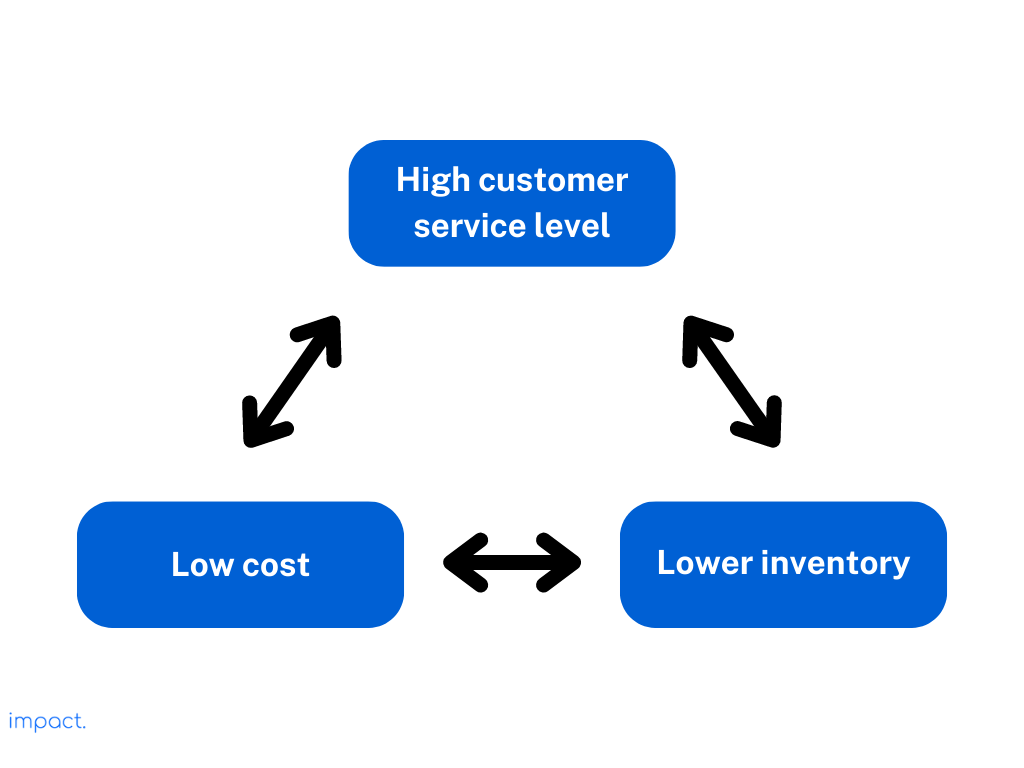

Managing trade-offs in a warehouse is very important for a warehouse manager’s job. The image below shows the leading exchanges.

Warehouse managers need to recognize and balance different trade-offs within the warehouse. Here are some examples:

Read more: 6 Warehouse Performance Metrics & Tips for Choosing Them

Warehouse managers today experience a range of pressures and challenges from different sources, both inside and outside their organizations. Here are the central challenges they face:

Companies want to spend less money on the supply chain. Transportation and warehouse managers face pressure to cut costs and make customers happier. The company must consider outsourcing specific tasks and thoroughly analyze how other companies handle logistics.

The supply chain has recently introduced new Key Performance Indicators (KPIs) called perfect order metrics. Achieving timely delivery without damage and with the correct paperwork defines an ideal order.

These metrics cover many aspects of supply chain performance. If everyone uses the same standards, they can become a leading measure for supply chains and help distinguish one company from another.

Order lead time refers to the time it takes for customers to receive their goods after placing an order. A well-run warehouse aims to minimize lead times, ensuring quality products at a lower cost. Having a shorter waiting time is a crucial factor that sets competitors apart.

Companies use different channels to deliver products and reach more customers. These channels include delivering single products to end users directly, sending specific stock-keeping units (SKUs) orders to stores, and fulfilling bulk orders to retail distribution centers.

Every shipment has different rules for collecting it and what equipment to use. It also takes time to process orders and use other shipping methods.

The just-in-time method and more online sales and initiatives like efficient consumer response (ECR) and quick response (QR) have made smaller but more frequent orders necessary. As a result, warehouse operations need to change from picking full pallets to picking cartons and individual items.

Companies should adjust their strategies to deal with uncertain sales. This adjustment means adding more resources during busy times and reducing operations during slower periods.

Having a wide variety of products is excellent for consumers, but it creates a problem for warehouse managers. They struggle to find the right storage spots that are both affordable and practical. If the picking locations are too high, it becomes difficult for workers to reach the products, which lowers productivity.

Retailers want to stand out by offering different product options. As a result, the company decided to change how they handle inventory in the warehouse. Instead of storing all products immediately, they only hold the basic stock and add more when they receive an order.

Warehouse managers need to find ways to attract new staff. Currently, they have hired workers from other countries to fill the gaps. One approach is to hire supervisors who can speak more than one language.

Another way companies can improve is by offering flexible working hours and shifts. According to Parkinson’s law, work takes up the available time. Lack of time can be a problem in warehouses with little stock. Companies can better match their resources to the demand by using annual hours.

Warehouses create much waste daily. Examples of these wastes are stretch-wrap, cardboard, tape, and pallets. So, warehouse managers must control this waste by saving costs, recycling, reusing, and converting energy. Energy use also affects warehouse products, such as lighting, equipment, and heating.

Supply chains create many data because their main job is to transfer information. Warehouse managers can use this data to analyze and track things. Being able to track goods in the supply chain is very important, especially for food and medicine.

The warehouse supervisor plays a crucial role in warehouse operations. They oversee many staff members, which depends on factors such as the nature of work, warehouse size, and the abilities of their supervisors and staff.

According to a recent survey conducted by Cranfield University (Baker and Perotti, 2008), the average ratio of operators to supervisors is as follows:

In the warehouses we have today, supervisors need to know how things work and be good at managing. According to Ackerman (2000), a good supervisor can encourage people to share their ideas and discuss them with their staff and colleagues. So, supervisors should have these essential qualities:

It’s essential to understand and communicate messages clearly and directly. When there’s miscommunication, it can cause confusion, waste efforts, and generate missed opportunities.

Managers and supervisors should not closely watch over tasks after delegating them, but they should still take responsibility. They need to keep an eye on task progress and give feedback to employees about their performance.

Supervisors and managers should understand their employees and adapt how they motivate and give feedback to meet each person’s needs. It’s crucial to provide consistent feedback to staff, even when they are doing well, just like when they are not meeting expectations.

Problem-solving and decision-making skills go hand in hand. To effectively utilize these skills, you must identify and develop options and take decisive action. As you walk around the warehouse, actively search for staff members waiting for something to happen before they can proceed with their tasks. Determine the cause of the bottleneck and make necessary changes to the process.

In today’s fast-paced warehouse environment, supervisors must be flexible and respond promptly to changes and urgent requests. Additionally, they need to supervise and carry out various tasks actively.

Warehouse supervisors must understand company policies and procedures to train operators effectively and coordinate their work. Supervisors need to be involved in preparing warehouse procedures and processes, as they need to know the administrative and operational steps involved.

Supervisors must share their knowledge with staff to keep things consistent and sustainable. When staff members receive proper training, they have a better chance of becoming supervisors in the future.

Supervisors must actively understand customer preferences and operation management to ensure customer happiness. At the same time, supervisors need to think about the costs and possible trade-offs.

Supervisors should assign company goals to their teams and clearly explain how the team will contribute to these goals.

Read more: Warehouse Cost: 2 Determination Systems & Reduction Tips

Warehouses need an experienced and knowledgeable manager who can train and motivate supervisors and operators to make it run well. However, finding the right employees is challenging due to an aging population.

Managers have to make choices when dealing with these challenges. They have to balance reducing costs and improving customer service. Comprehensive and ongoing training enables managers and supervisors to acquire the necessary skills.

In the next chapter, we’ll talk in detail about the picking process in the warehouse and its related procedures.

Ackerman, K. B. 2000. Warehousing Profitably. Ohio: Ackerman Publications.

Baker P, Perotti S. 2008. UK warehouse benchmarking report. Cranfield School of Management.

Richard G. 2011. Warehouse Management. Great Britain: Kogan Page Limited.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

In the bustling business world, warehouses are crucial as storage and distribution centers for all kinds of products. Whether a small local shop or a big international company, warehouses are vital for keeping things organized and ensuring goods reach their destinations.

Understanding what warehouses are and why they matter is essential for businesses aiming to succeed in today’s fast-paced market. This article will explore the definition of warehouses, their various functions, and why they are so crucial in business.

By shedding light on this critical aspect of business, we hope to provide valuable insights into the world of warehousing and its impact on modern commerce.

A warehouse is a place where businesses store their goods. Manufacturers, importers, exporters, wholesalers, and customs use warehouses.

The warehouse plays a crucial role in the supply chain. The supply chain’s main job is to ensure the correct product gets to the right customer, at the right place and time, in the correct amount, condition, and price.

The warehouse has an essential role in the supply chain. Here’s how it contributes:

Historically, we use warehouses to store stock and act as a middleman between producers and consumers.

However, this setup has some issues. One problem is that it’s difficult to know how much stock is available throughout the supply chain, and the flow of information is slow. As a result, companies end up having more inventory than they need.

Warehouses also serve as storage for raw materials. In the past, when land and building prices were lower, it was customary for companies to store large amounts of raw materials and finished products.

Production processes are time-consuming. As a result, companies produce goods with the hope of consumer purchases and often keep more stock than necessary.

Because land, buildings, labor, and energy costs are high, companies are trying to reduce their stock and speed up production. To do this, they use different methods like Just-In-Time, Efficient Consumer Response, and Quick Response.

The way we manage the supply chain has changed. Instead of pushing products into the market, we let the market pull them in.

To make our warehouses more efficient and save money, we need to understand why we stock up in the first place. This understanding is crucial to avoid keeping unnecessary stock.

Read more: Warehouse Cost: 2 Determination Systems & Reduction Tips

Right now, businesspeople must keep stock in different supply chain processes because the community and market conditions are uncertain. Here are the reasons why we need to hold goods:

Suppliers of products like sun lotion and umbrellas will face fluctuating demand due to weather changes. Shifts in the weather directly influence the market, resulting in expected erratic patterns. Additionally, unexpected sales spikes can occur during new product launches or when a team wins a major competition like the World Cup.

The trade-off lies between the cost of holding additional units and the higher transportation costs for smaller batch shipments. Moving products in large quantities generally leads to lower unit costs. Lower transportation costs will require more storage space to be available.

Buyers are attracted to the possibility of lowering unit costs through bulk purchases. However, this approach can backfire if the company fails to sell all the extra products or has to sell them at a loss to clear the warehouse. In such cases, sellers must calculate each item’s lifetime cost before buying more.

Sellers store additional stock in the warehouse because the goods may need to travel long distances, depending on their manufacturing location. The options are to use costlier local suppliers and manufacturers or to spend more on transportation and safety stock.

Many companies and manufacturing businesses temporarily close their operations during holidays, machine maintenance, and stock counts. Retail stores and wholesalers must ensure they have enough stock to meet customer demands before shutting down. Similarly, manufacturing companies increase their inventory of components to ensure uninterrupted production when suppliers are closed.

Modifying production lines to accommodate changes in models, colors, design features, and other factors can be expensive. Balancing the lower costs per unit achieved through longer production runs with the additional storage costs per unit is necessary.

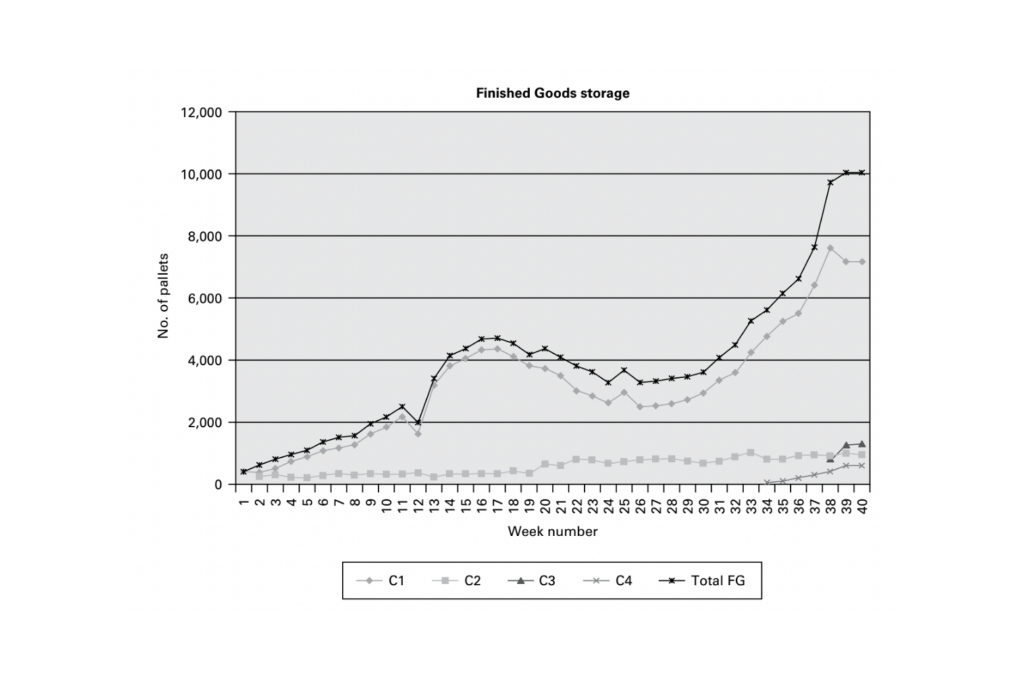

The picture below shows how chocolate manufacturers increased their stock during Easter. You can see that the number of pallets used for storage went up from 500 to 10,000 at its highest point. This image tells us that during certain times of the year, like Easter, the demand for chocolate increases, so they need more stock.

Source: Gwynne Richards; Warehouse Management; The role of the warehouse

Manufacturers must keep spare parts in stock to avoid disruptions in production. While this can be costly, it’s a necessary trade-off between the pieces’ expense, storage costs, and potential damage to the production line and its effects.

Companies are producing more items in preparation for orders. For example, a chocolate maker creates Easter eggs before accepting orders. They will finish the process once they know what type, packaging, style, and inserts are needed.

Read more: Work in Progress (WIP): its Definition and Functionalities

Some products, like fine wines, cigars, precious metals, stones, and fine arts, can become more valuable the longer they are stored.

Both public organizations and private companies must retain documents for a certain period. They must keep these documents as they serve as legal requirements, including invoices, financial records, letters, and more. Additionally, patient forms from emergency services also fall under this category.

Third-sector companies need to store necessary equipment in case of natural disasters. They should keep items like tents and survival kits stored and easily accessible.

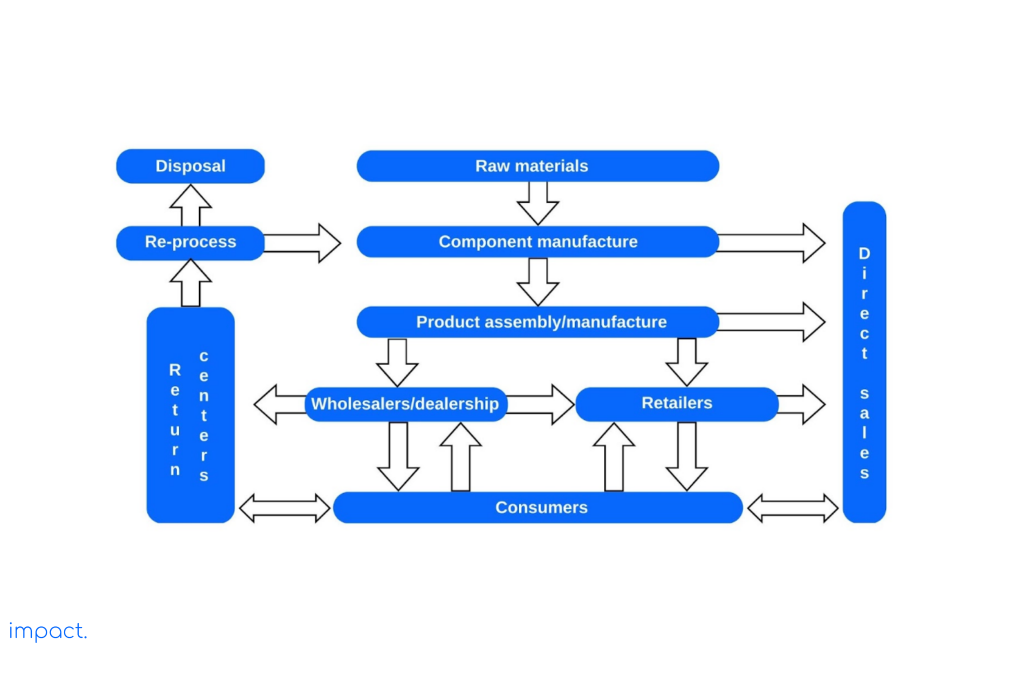

Every warehouse in the supply chain process has a specific job. The diagram below illustrates that raw material producers, manufacturers, retailers, and logistics companies operate warehouses. Here are the different types of warehouses based on what they do:

This warehouse type stores raw materials and components near the manufacturing point.

This warehouse keeps products at different production stages and makes them personalized before sending them to customers. The suspension and sub-assembly tasks include:

This warehouse holds products for manufacturers, wholesalers, and retailers. It serves as a backup storage to help these companies when they need to increase their stock. These situations include product launches, high-demand periods, and seasonal spikes.

The pooling center gets products from different places. It puts them together to send them to customers or the production process. It can also work as a retail warehouse where products from other suppliers are stored and combined for the next shipment. Unlike a cross-dock center, where products can wait for instructions, this warehouse moves things along quickly.

The transshipment center gets products in large amounts from suppliers. Then it splits them into smaller quantities for delivery to different places.

Having operational activities that can swiftly move goods is essential to ensure a quick and efficient consumer response in retail. One such activity is cross-docking, which involves labeling and preparing products for the immediate shipment before sending them to the center. During this process, products are identified and grouped with other shipments.

Cross-docking is especially useful for perishable items that must be transported quickly, such as fruits, vegetables, meat, and fish. The aim is to deliver these products on the same day, which is why cross-dock centers are considered the future of warehousing.

Sorting centers primarily serve companies that distribute mail, parcels, and pallets. They gather items from different parts of the country and send them to sorting centers, where they organize them based on zip or postal codes. Then, the items are assembled and shipped overnight to distribution areas for onward shipment.

Retail is also adopting automated sorting centers. Pallets are stacked using a mini-load system for temporary storage and retrieval when they arrive. This process continues until the final stage of automated manufacturing before leaving the facility.

The rise in online shopping has led to the construction of more customer fulfillment centers. The design of these centers makes it possible to handle large orders of single items.

Instead of picking groceries from the store, people now get home delivery orders from retail grocery fulfillment centers. These centers also handle returns because online shopping has a higher return rate than regular in-store shopping.

Nowadays, companies understand that returning products or getting rid of them can affect their money flow. That’s why they have created special warehouses just for handling returned goods.

Retailers hire third-party contractors to help customers return items they don’t want or have defects. These contractors collect the items and send them to a return center for inspection and actions like repackaging, repairing, recycling, or disposing.

Warehouses support commercial operations and the public sector, including the armed forces and the third sector. With the increase in natural disasters, third-sector organizations are setting up warehouses in strategic locations across the globe. It allows them to be closer to disaster areas and respond more quickly when help is needed.

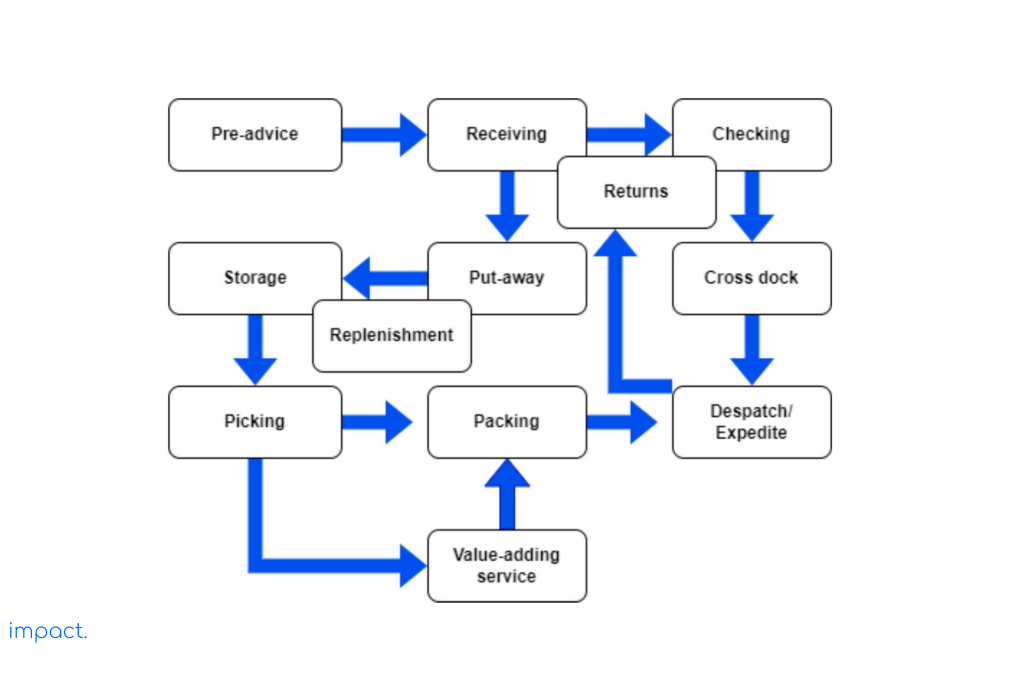

Warehouses have various types based on size, style, function, ownership, and location. Despite these differences, the underlying process remains consistent.

The process involves pre-receipt, receiving, put-away, storage, picking, replenishment, value-adding services, and despatch (delivery). Refer to the image below for a visual representation of the warehouse process.

When companies do things correctly and run smoothly, they can improve accuracy and efficiency in their warehouse operations. They can also make complex tasks more manageable by using new available technologies.

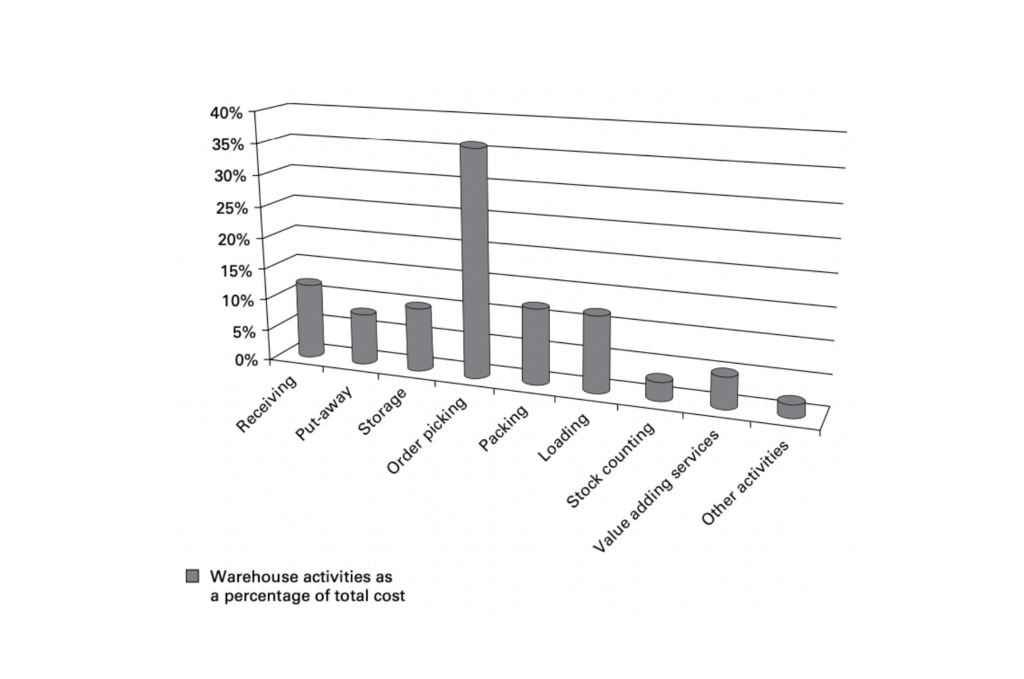

The image below shows that picking orders usually cost the most in warehouses. However, the specific costs can vary depending on the type of warehouse.

Source: Gwynne Richards; Warehouse Management; Warehouse processes: receiving and put-away

Read more: 6 Warehouse Performance Metrics & Tips for Choosing Them

The warehouse plays a crucial role in the supply chain by ensuring the right product reaches the right customer in the right place, time, condition, and price. It is no longer just a storage space but a vital link in the supply chain.

To cope with rising costs, warehouses must enhance their efficiency. It involves closely monitoring the supply chain, improving forecasting capabilities, and optimizing the accuracy and flow of information.

Warehouse managers actively contribute to the smooth operation of activities. In the next chapter, we will delve deeper into the responsibilities of warehouse managers.

In the upcoming chapter, we will delve deeper into the role of the warehouse manager.

Richard G. 2011. Warehouse Management. Great Britain: Kogan Page Limited.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

Company culture starts with the people in it. Human Resources (HR) is crucial in lean manufacturing as the heart and soul. At Toyota, HR is at the center, providing the most essential input for the company: its workers.

HR is also vital in supporting a thriving lean culture within a company. Let’s now explore lean culture in more detail, including its definition, how it came to be, and the factors contributing to it.

Organizational culture includes how team members experience their daily work and what they do. On the other hand, lean culture puts customers first and always looks for ways to get better.

In a lean culture, team members treat each other equally and respectfully. This interaction creates a collaborative environment where there’s no competition between workers.

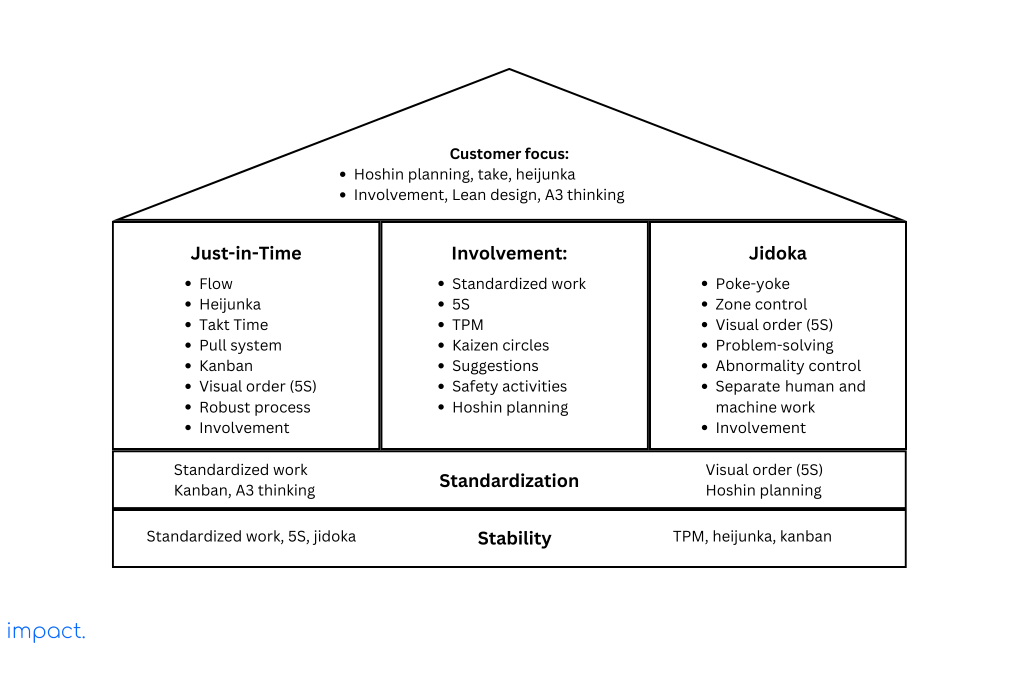

Four pillars form the foundation of lean culture. These pillars are:

Read more: Lean Manufacturing: Definition & 3 Benefits

We need everyone to spot and remove waste to create a lean culture. It means working together and sometimes changing how we think. However, more importantly, it’s about agreeing on what we consider wasteful or valuable. Here are two things to remember when building a lean culture:

Leadership in a company has a significant impact on things. Managers must take charge, start conversations, and show good examples. In a lean culture, the manager’s job is to handle the work, not the people. By managing the workflow, we can create a team where everyone works together to achieve the goals.

The cultural framework is essential for both new employees and existing team members, who sometimes wonder how they should act. It provides guidelines and expectations for everyone in the organization. When companies create a framework that lists standards and desired behaviors, it brings clarity and agreement on how to do things. The framework helps everyone understand their expectations.

Six supporters drive the formation of a lean culture and are actively present in companies that embrace lean principles. Here is a breakdown of each type:

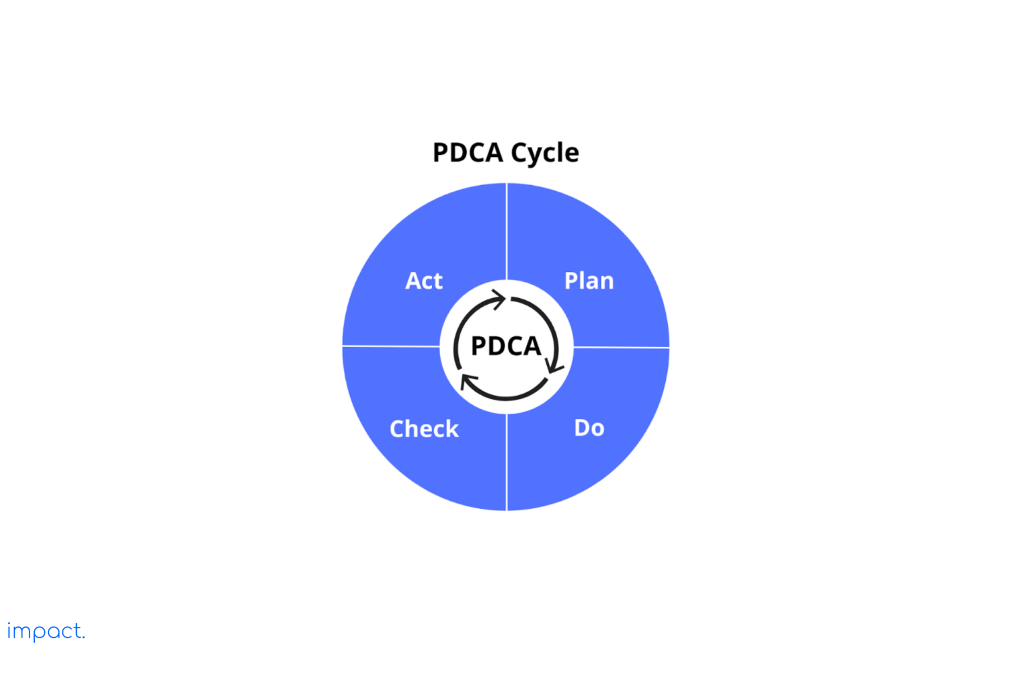

PDCA is a simple four-step method that helps avoid mistakes and improve business processes. It’s an essential activity for managers. Here are the key points:

For effective learning of PDCA, practicing it under the guidance of an experienced mentor is recommended. The HR department should also consider how to support mentoring in our organization.

The company must establish its direction and goals to create a plan. It should then provide different ways to achieve those goals. A good plan should include the following:

The critical planning results are Gantt charts, backup plans, and control panels or dashboards.

Do has its own PDCA cycle, emphasizing the importance of trying things out before fully implementing them. Conducting successful trials helps us strengthen and validate our plans.

PDCA requires assessing team members’ abilities objectively to avoid any skill gaps. Human Resources must clearly understand what “capability” means to evaluate the current situation and take appropriate actions accurately.

Companies must make several decisions when it comes to checking and confirming information. They need to determine whom to check with, what to check when to check, how often to check, and how to conduct the checks. This process enables companies to gain a comprehensive understanding of all the events taking place within the company.

The “go-see” approach is crucial because it accurately accounts for what occurred and eliminates the risk of errors by merely checking

Acting involves thoughtful consideration of a situation and subsequent action. It encompasses two key aspects:

Experience has taught us the importance of being prepared. We use temporary measures to address minor issues and permanent solutions to the root causes. Companies should also stay focused on taking action while considering future gaps in skills and training needs.

The previous chapter discussed how standards are crucial in Lean manufacturing systems. They are a powerful tool for continuously finding better ways to do things.

Companies have the freedom to create their standards. Rather than constantly reprinting documents with changes, it is more efficient to maintain a record of the changes and their corresponding dates. It’s essential for the standards to clearly state what is considered normal and what falls outside of that.

Let’s take a messy workplace without standards as an example. It’s difficult to spot problems like equipment leaks in such a place. On the other hand, if the workplace is clean and has clear standards, any abnormal conditions can be quickly identified and fixed.

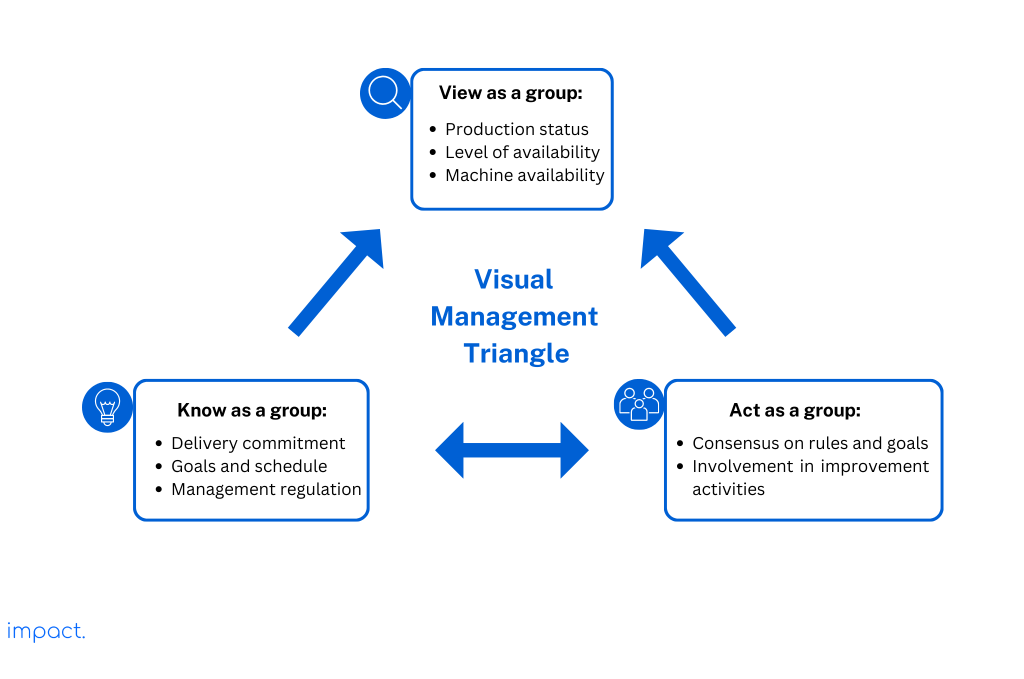

Visual management is a technique that utilizes images and minimal text to achieve the visual management triangle. The accompanying image demonstrates this concept.

Visual management is a way to show and explain how the company’s work system operates. Toyota treats visual management like a play, organizing events on the shop floor to make problems easy to see. Here are some of the events they do:

Working together as a team is crucial for achieving goals. Here are some ways to improve teamwork in a lean culture:

Read more: Employee Involvement: Significance & 3 Supporting Factors

Lean manufacturing is full of unique and exciting paradoxes. Paradoxes are things that go against common beliefs. Here are some examples of the paradoxes in lean manufacturing:

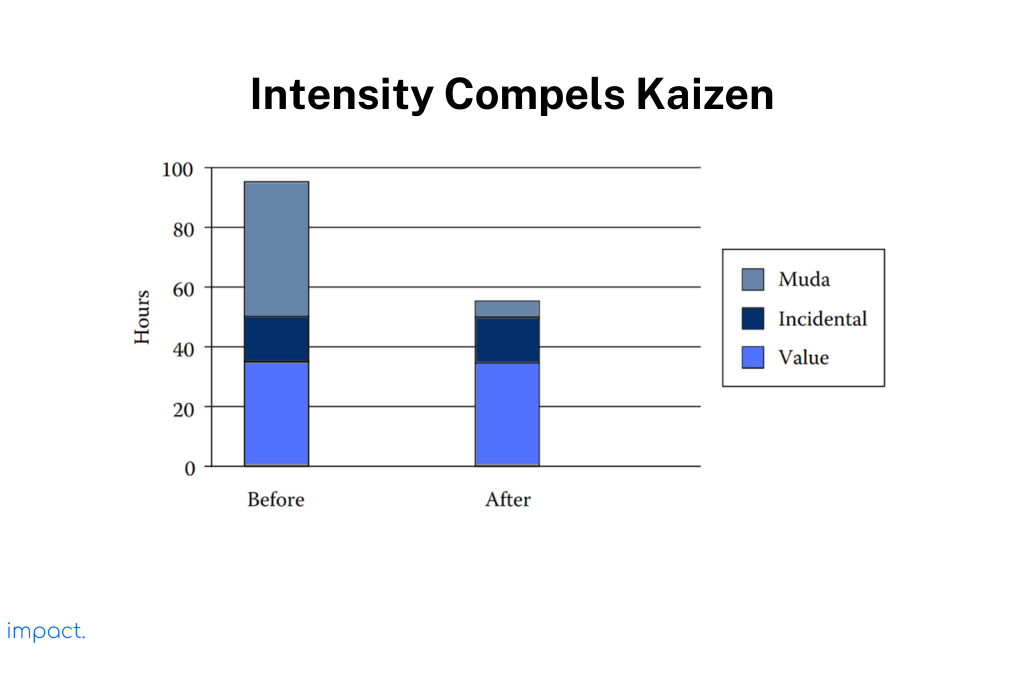

PDCA, standardization, and visual management build a solid lean culture. This culture promotes Kaizen, a continuous improvement process that aims to reduce waste in manufacturing through minor ongoing improvements.

Without Kaizen, a Lean manager may work 90 hours per week. However, with a culture of intensity, managers can easily spot areas for improvement and value, which helps reduce their working hours.

Managers must stay close to their teams and provide support when needed while keeping the intensity high. As the company eliminates inefficiencies over time, work becomes more efficient.

A lean culture is all about focusing on customers and constantly improving. Six critical factors support a lean culture: PDCA, standardization, visual management, teamwork, intensity, and paradox.

Everyone in the company needs to participate actively to create a lean culture. Managing human resources within the company has become simpler using HCM Impact. It’s a tool that automates HR management processes.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

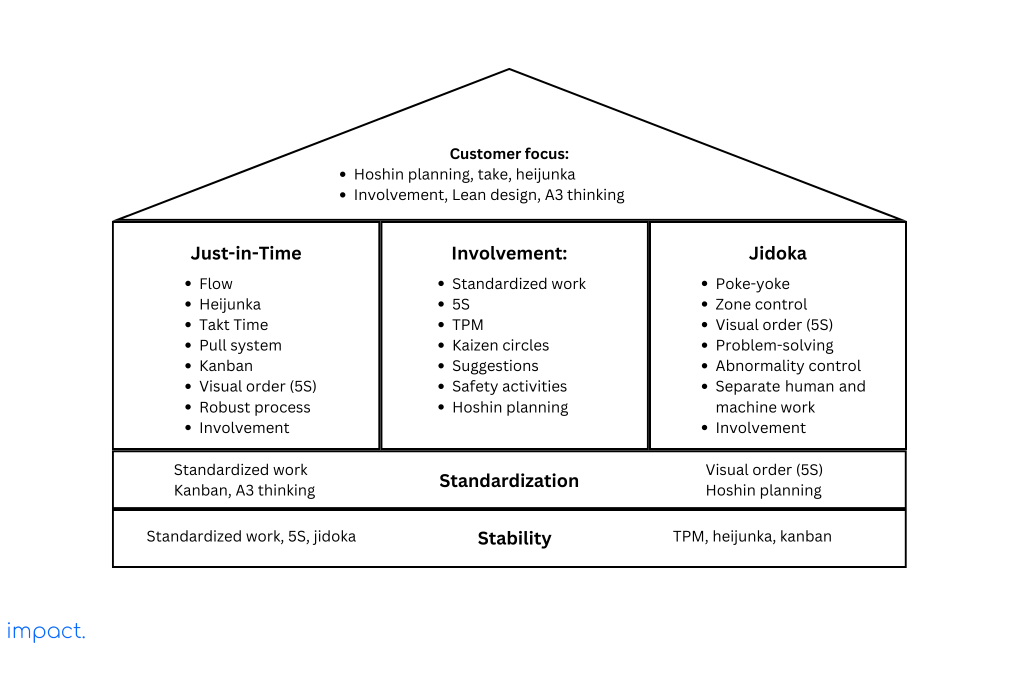

Hoshin kanri, or Hoshin planning, is an integral part of the House of Lean Production that encourages employees to be involved in company planning.

Every company needs clear goals and a well-thought-out plan to achieve them. Hoshin Kanri helps companies by identifying goals, figuring out the best ways to reach those goals, and supporting the actions required.

Let’s dive deeper into Hoshin Kanri, starting with what it is and the four phases of its application.

Planning is figuring out how to gain an advantage and achieve goals by making a strategy. It involves answering two critical questions: (1) Where are we going? and (2) How do we get there?

There are four types of planning commonly used in modern organizations:

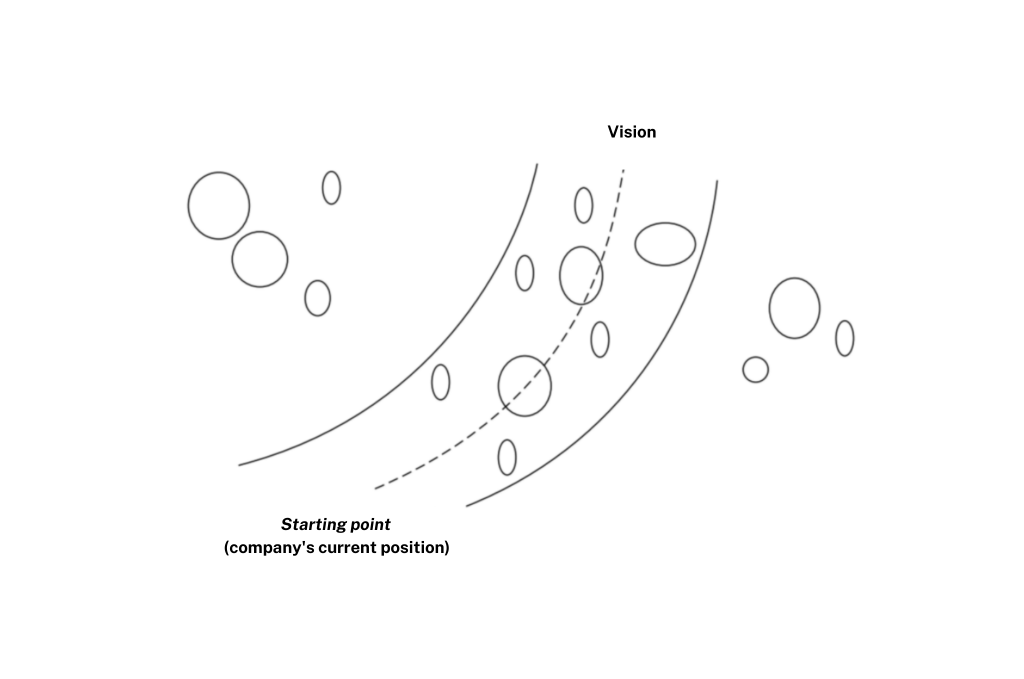

This chapter emphasizes strategic planning, focusing on goals and their methods. To create an effective plan, the company must grasp critical aspects, including its current position, the desired goals (vision), the plans to attain those goals, and potential problems and obstacles.

Here is a visualization of a company’s planning process as it progresses toward its goals:

Source: Dennis, P. (2017). Lean production simplified; Road Metaphor.

Planning is essential for companies because it helps them create a shared vision of where they want to go and how to get there. In Lean manufacturing, planning works like a pull system, where the idea is so convincing that it pulls the company into the future.

Planning also helps improve the abilities of individuals and the company. It encourages new ideas and innovation and helps the organization learn and grow.

It’s essential to consider the company’s strengths and weaknesses and take action to prevent problems for an effective plan. Planning also helps keep the company motivated by setting new goals regularly and avoiding complacency.

Mintzberg’s influential work, “The Rise and Fall of Strategic Planning,” reveals some problems with traditional planning. These problems include:

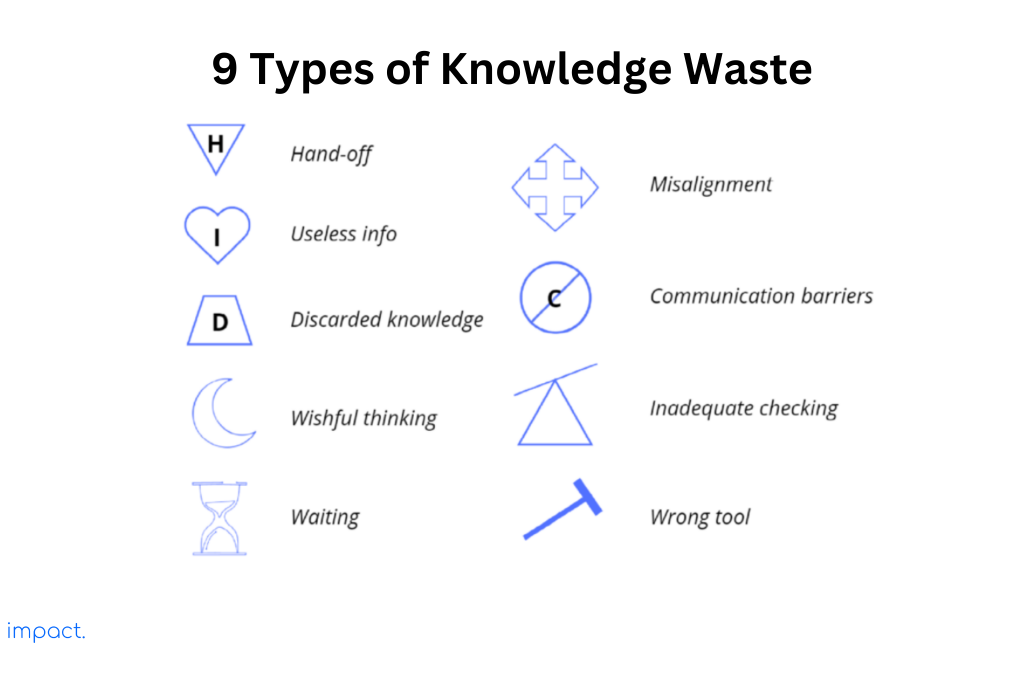

Planning problems often arise due to disconnections within departments (horizontal), between departments (vertical), and over time (temporal). These disconnections result in wasted knowledge and inefficiencies. The figure below displays nine symbols representing specific types of knowledge wastage.

Most companies have a lot of energy and talented people but still struggle to reach their goals. To overcome this challenge, companies can create a smooth knowledge flow, experience, and creativity within the organization.

By using Hoshin Kanri or Hoshin planning, companies can involve everyone in the company and effectively solve strategic problems.

Hoshin Kanri is how a company manages its goals and ensures it goes in the right direction. “Hoshin” means direction or purpose, and “Kanri” means management or managing. In simple terms, Hoshin Kanri is the company’s way of setting and achieving goals while staying on track.

Hoshin Kanri, also known as Hoshin planning, is like the nervous system of Lean manufacturing. It helps businesses figure out what they must do in the short-term (one year) and long-term (three to five years) to succeed. It’s all about identifying those needs and helping employees develop their skills.

To make it happen, Hoshin Kanri brings together all the company’s resources and ensures everyone is working towards the same goals. It uses a cycle called PDCA (Plan, Do, Check, Action) to keep things on track and get the results they want.

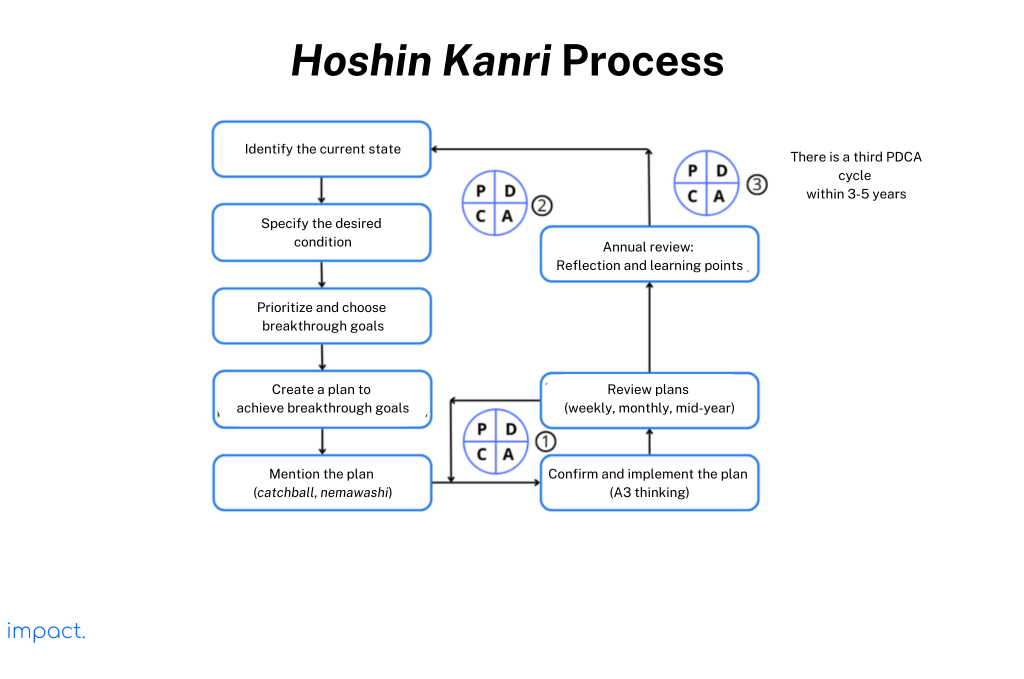

The Hoshin Kanri method follows a simple 7-step process:

Read more: Lean Manufacturing: Definition & 3 Benefits

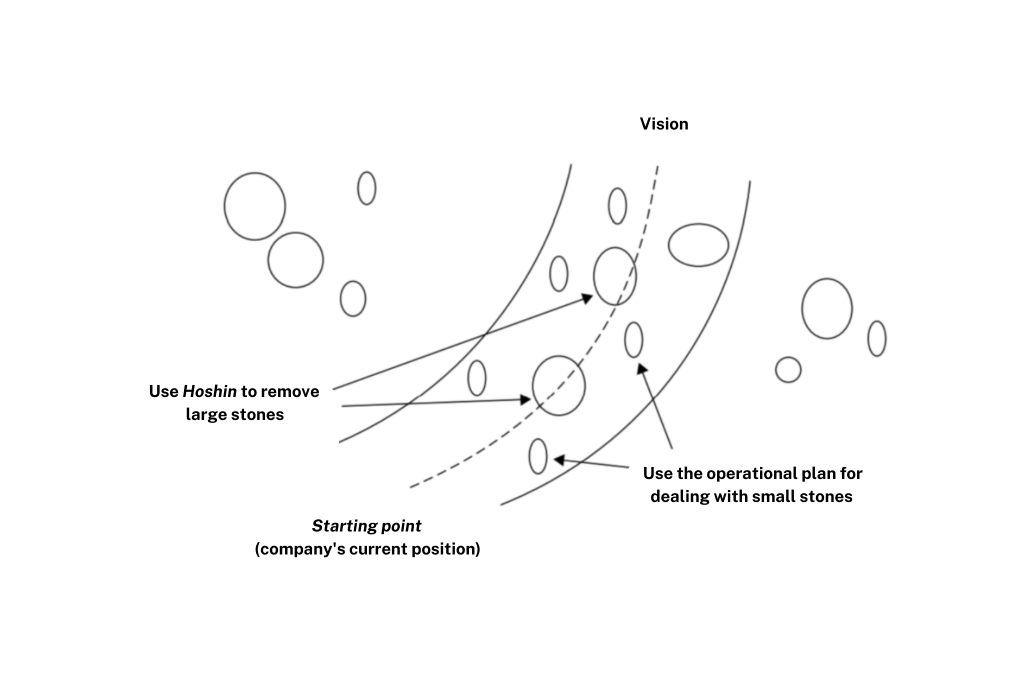

Hoshin Kanri focuses on essential issues for improvement, represented as big stones. It uses an operational plan to handle routine work like small stones. However, a common mistake in Hoshin Kanri is trying to do too much, draining energy and leading to no real achievements.

Source: Dennis, P. (2017). Lean production simplified; The road metaphor with problems targeted.

In Hoshin Kanri, companies need to align resources and promptly adapt to changes in the flexible business environment. This approach helps them stay on track and respond effectively to any shifts or challenges that come their way.

Hoshin Kanri improves upon Management by Objectives (MBO), a concept introduced by Peter Drucker in his 1954 book “The Practice of Management.” It takes MBO’s strengths and fixes its weaknesses.

Hoshin Planning system includes improvements such as Plan-Do-Check-Act (PDCA), Nemawashi, Catchball, control department concept, and A3 thinking. Let’s take a look at each of these systems:

The PDCA cycle is a crucial model in lean manufacturing for implementing changes. It provides a four-step method that helps teams improve processes and prevent repetitive mistakes. Here is a concise explanation of each PDCA step:

Hoshin Kanri incorporates multiple overlapping PDCA cycles, including:

PDCA requires a management system that shows everyone what’s going on and stops problems from happening. This system includes both formal and informal reviews.

Formal reviews should happen three times yearly: at the year’s beginning, middle, and end. The year-end review summarizes past events and assists in planning for the next year (which the management team presents in January).

Informal reviews involve the management team providing daily status reports, department heads reporting progress in weekly meetings, and conducting shop floor process reviews. These casual reviews are crucial in keeping everyone informed and detecting problems early.

Nemawashi is a way to reach an agreement and create harmony. Before putting it into action, Nemawashi involves discussing the plan with all the customers who would be affected. It also includes making changes to the program based on their feedback.

Catchball is the process of managers at different levels exchanging ideas and feedback during planning. It helps strategy and tactics to spread throughout the organization.

Catchball connects the officers’ vision with the day-to-day activities of the shop floor team members. Here’s how it works:

The control department is essential for solving the problems that many organizations face. Different groups must work together regarding important areas like productivity, quality, cost, and safety.

For instance, groups like Manufacturing, Purchasing, Production Control, Engineering, Maintenance, and Quality must collaborate to meet quality goals.

Regarding quality, the control department coordinates activities among these groups to achieve company objectives. Some of their tasks include:

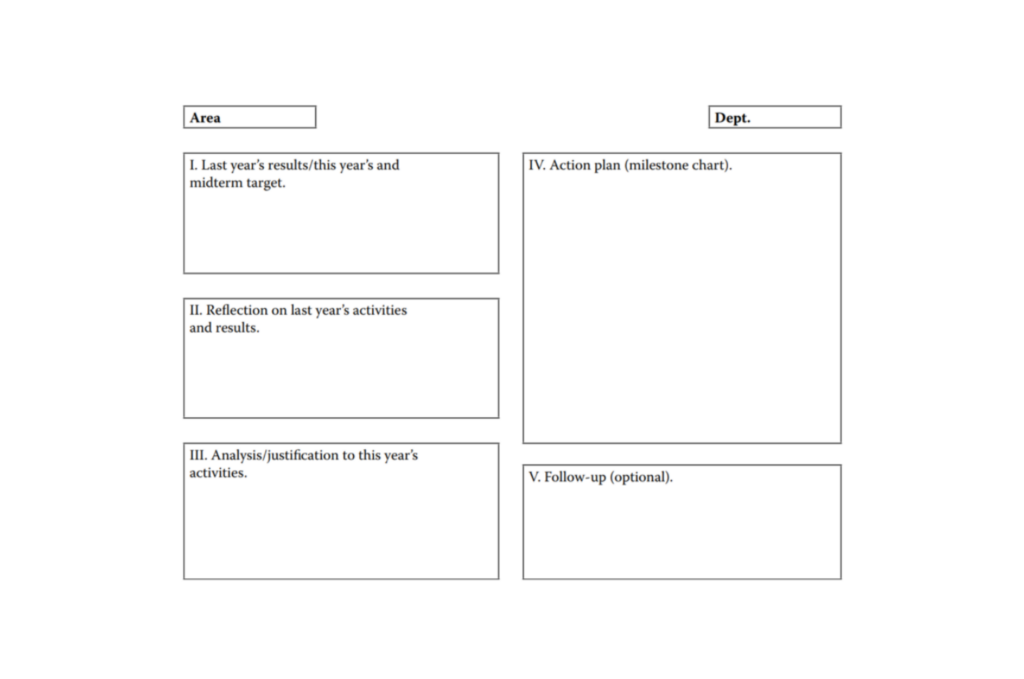

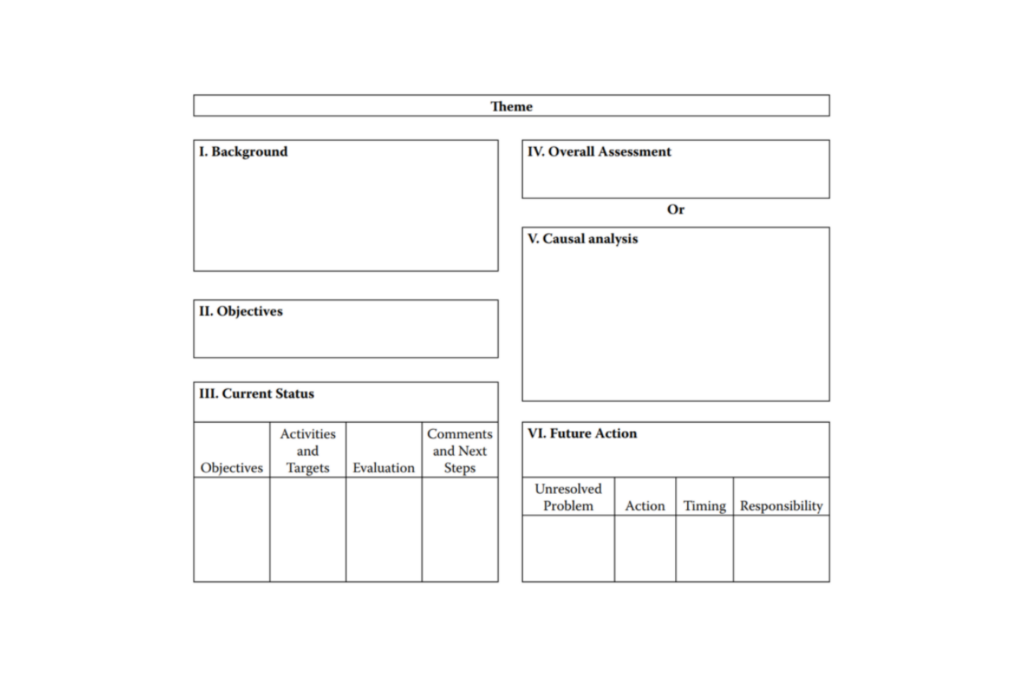

A3 is a way of thinking based on PDCA, nemawashi, and catchball. A good A3 shows that you understand the situation well and know how to use Lean tools effectively.

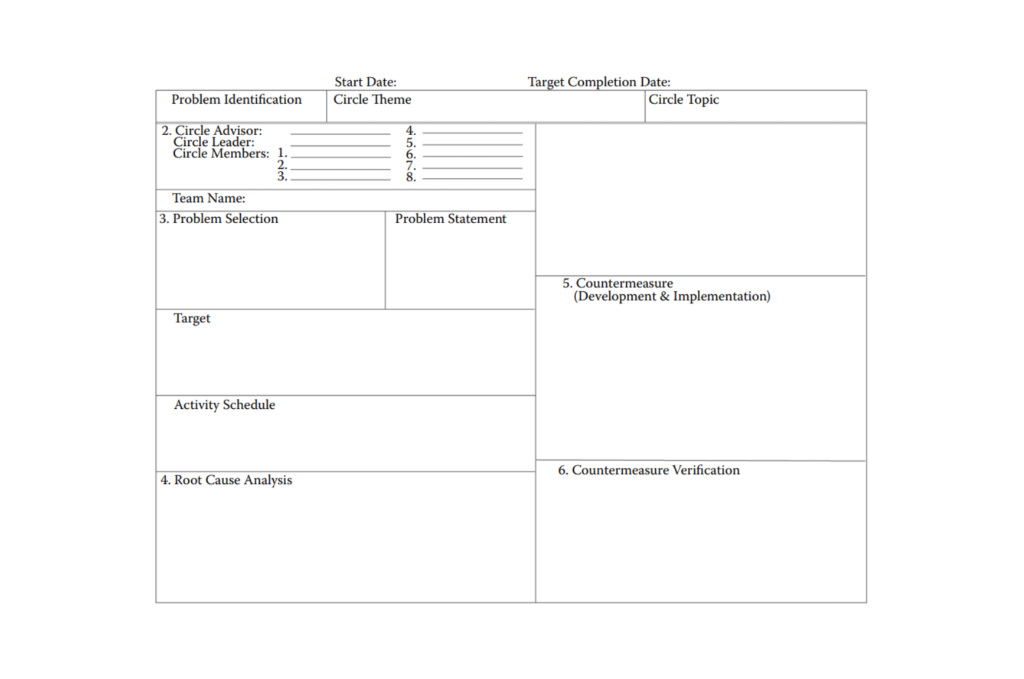

An A3 report is a simple one-page document printed on 11″×17″ paper. Toyota started using A3 in the 1960s to summarize the Kaizen Circle Activity (KCA), and it has become Toyota’s most helpful communication tool.

There are four types of A3 documents:

The main challenge in writing A3 lies in the varying report formats employed across different departments or sections. Another issue is the “better by the pound” syndrome.

Take a look at the image below. It shows the format of the Hoshin Kanri A3, which is essentially a storyboard following a standard and logical structure. You can adjust the layout to show the current situation or address any problems.

Source: Dennis, P. (2017). Lean production simplified; Hoshin Kanri A3.

The image below displays the current A3 status format for reporting hoshin progress.

Source: Dennis, P. (2017). Lean production simplified; Current status A3.

Hoshin Kanri consists of four phases: Hoshin generation, Hoshin deployment, Hoshin implementation, and final evaluation. Let’s break down each stage and see what it involves.

The first step is called “hoshin generation,” where the company sets its annual and departmental goals. Senior management collaborates with subordinates to discuss processes and outcomes to achieve this.

Let’s examine how we can apply this first step in the quality department. The goal is to reduce the overall damage rate by 20% before the year ends. We will achieve this by:

In this phase, you must set specific goals and plans at different levels within and across departments. To accomplish this, teams should discuss and share ideas (nemawashi and catchball). At each station, the focus should be on converting hoshin goals and means into practical actions.

For example, the assembly department wants to reduce defect rates by 25%. To achieve this, they will:

When you implement hoshin, you’ll get results like tree and affinity diagrams and the A3 strategic plan. These things are developed step by step through listening to everyone’s input.

In the first year of hoshin planning, each level typically takes around two weeks to reach an agreement and create a shared strategy in A3 format. However, as you move into the second year, the process becomes faster and can be completed more quickly.

This phase is about putting the developed hoshin into action through management activities. It includes carrying out several PDCA cycles. Throughout the year, there should be formal and informal reviews to keep track of the current status and countermeasures.

In the year-end assessment of each hoshin kanri, we determine if we achieved the process and outcome objectives. We analyze what we learned and identify ways to strengthen our abilities. By answering these questions, we can evaluate whether Hoshin Kanri has been implemented effectively or requires improvement.

A learning organization is about improving our actions by gaining better knowledge and understanding. It means constantly learning and growing to make our efforts more effective.

Hoshin Kanri is an integral part of Lean manufacturing that involves everyone in the company working together to create strategic plans. It helps align resources and goals effectively.

The Hoshin planning system includes PDCA, catchball, nemawashi, the control department concept, and A3 thinking. Hoshin Kanri has four phases: development, deployment, implementation, and evaluation.

In the upcoming chapter, we will delve into Lean Culture.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.

Involvement is a crucial aspect of the House of Lean Production. When all employees are involved in the company, it becomes easier to spot problems.

Active involvement is crucial in any company and requires careful management, like the production process and product quality. Before implementing it, companies must identify the appropriate method and the skills needed to establish long-lasting engagement.

This chapter will delve into the concept of involvement in more depth, including its definition, purpose, and methods.

Involvement means taking part in an activity. It is crucial to involve everyone in the company to enhance daily operations and find solutions to issues.

Managers used to question whether shop floor workers, who had limited education, could contribute to business decisions. Today, employees are more educated and skilled. That’s why it’s imperative to include them in decision-making. It helps make the company’s outcomes better.

Having a system that is respectful and free from unnecessary difficulties is crucial to maintaining employee engagement. In Lean manufacturing, teamwork involves specific procedures, activities, and behaviors that allow team members to work independently, solve problems, and improve their daily tasks.

When team members are free to work independently, they can continuously improve their skills and contribute the most to the company. This approach also helps boost employee involvement and motivation.

Read more: Lean Manufacturing: Definition & 3 Benefits

The main goal of involving employees is to improve different areas of the company, like productivity, quality, cost, delivery time, safety, environment, and morale (PQCDSM). To achieve this, the company takes the following steps:

In previous chapters, we discussed engagement tools like 5S, TPM, and standardized work. Let’s focus on three main activities supporting company involvement: Kaizen Circle Activity (KCA), Practical Kaizen Training (PKT), and suggestion programs. Here’s a description of each method:

Kaizen, also called continuous improvement, comes from Japan and is a crucial part of lean manufacturing. Its goal is to eliminate waste and inefficiency in manufacturing by regularly making minor improvements.

These improvements include streamlining manufacturing steps, optimizing inventory management, boosting productivity, and enhancing quality control. The Kaizen Circle Activity (KCA) is the most popular engagement activity linked to Kaizen.

KCA has many benefits for employee involvement. Here are a few:

Managers form the KCA and become sponsors when they encounter a problem. A circle typically comprises six to eight team members who convene weekly for at least an hour, spanning a period of six to eight weeks. The team presents their accomplishments and future strategies to management.

The table below outlines the roles and responsibilities of the Kaizen circle. Specific positions may be discretionary. For instance, an experienced team may not require a coach. A seasoned area supervisor can be a facilitator and advisor in such cases.

| Role | Responsibility |

| Circle member | Attend meetings, contribute ideas, select and analyze problems, recommend and implement solutions, and make presentations. |

| Facilitator | Attend training, guide team members through the problem-solving process, attend circle meetings, and complete & submit KCA meeting notes. |

| Advisor | Attend training, provide technical or administrative advice as needed, attend circle meetings, and help coordinate presentations to management. |

| Circle trainer | Develop and conduct training, attend circle meetings when requested, provide problem-solving exercise, and collect meeting notes and management reports. |

| Manager | Encourage circle formation and involvement, regularly check circle progress, provide suggestions, approve recommendations, and attend presentations. |

KCA training usually takes about four hours. To successfully create circles, team members need to undergo training in the following skills:

KCA requires a control department to oversee and handle administration. The main administrative tasks include:

The human resources team can function as the control department for all engagement activities. Here is the general format of a Kaizen circle report:

Source: Dennis, P. (2017). Lean production simplified; Kaizen circle activity (sample report format).

To promote KCA effectively, employ the following strategies:

Managers help promote KCA. They talk to team members daily about important company issues and problems in their area. They also share what management expects from KCA on essential topics.

KCA themes should be simple, like quality or security, when starting. As team members progress, KCA can actively focus on specific company goals, such as reducing certain quality defects or improving assembly processes.

In addition, managers must:

Practical Kaizen Training (PKT) is a one-week intensive program that aims to train team members and supervisors and improve specific processes. Each PKT consists of three to four team members, multiple teams, and PKT instructors or coaches. The training is structured as follows:

Ensure that training for small equipment is readily available and actively encourage workers to participate and develop these skills. The PKT training should specifically address the needs of youth, standardized work, and Kaizen.

Each PKT must provide clear, simple work charts for new design processes or physical changes to achieve the desired outcomes. These charts will promote a shared understanding among all participants involved in these processes.

To achieve success in implementing PKT in companies, companies must focus on the following key factors:

The primary purpose of effective suggestion programs is to involve everyone in the company by directly sending team members’ ideas to management and rewarding their initiative. Management needs to create a positive work environment with specific essential values to make this happen:

Supervisors and area managers should encourage team members to get involved. Here are some simple activities to consider:

Successful suggestion programs possess five key characteristics. These characteristics are as follows:

Make the program rules clear and straightforward. Clearly define the standards for completion time and rewards. A good approach is to assign merit points for each suggestion. Team members can redeem these points as they progress. In addition to cash, we can also give gift vouchers as rewards.

Ensure that the suggestion form is concise and fits on one page. It should include the following information:

Supervisors should assist team members in completing and submitting suggestions. Summarize the program rules and standards on the back of the form. Include both tangible and intangible recommendations.

Set clear standards for feedback, stating, “We will respond to all suggestions within one week.” Having well-defined processes and standards helps us respond quickly. Evaluators play a vital role in reviewing suggestions and recommending appropriate recognition levels.

Make sure each department has enough evaluators to meet the turnaround standards. Companies can also invite evaluators to a special dinner as part of an advisory program and present an award for the “Evaluator of the Year.”

Maintenance groups sometimes have an unfair advantage when enjoying the benefits of advisory programs. Lack of access can lead to resentment and harm the program’s reputation. To prevent this, companies should establish fair rules that treat all groups equally.

Promote advice programs through the following channels:

To measure the effectiveness of promotions, consider the following steps:

Cash and prizes are standard rewards in suggestion programs but don’t provide the strongest motivation. Psychological research suggests that other factors, called intrinsic motivators, may be even more critical. These inherent motivators include:

In suggestion programs, the fundamental principle is “prioritize quantity over quality.” A suggestion program typically takes three to five years to generate a substantial quantity, such as yearly five to ten suggestions per team member. Once the company achieves an adequate volume, it can focus on improving its quality.

We must establish a yearly hoshin culture to set goals for KCA, PKT, and suggestions. The plans for KCA may include the following:

It’s crucial to effectively manage engagement to ensure its long-term sustainability and help companies increase their profits.

Involvement is vital in Lean manufacturing. It helps team members develop their skills and increases the chances of long-term success. Three activities support successful participation in the company: kaizen circle activities, practical kaizen training, and suggestion programs.

Supervisors and managers play an essential role in keeping engagement high. Engagement activities should be fair, easy to participate in, and provide both external and internal satisfaction. To maintain attention, companies can create a hoshin culture. The next chapter will discuss hoshin planning as part of involvement.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Ask about digital transformation, our products, pricing, implementation, or anything else.

We are excited to be part of your transformation journey from day one.